ABS composition easy to process in laser welding and preparation method thereof

A laser welding and easy-processing technology, which is applied in the field of laser welding and easy-processing ABS composition and its preparation, can solve problems such as poor processing performance, achieve the effects of improving heat resistance, improving welding strength, and widening the process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

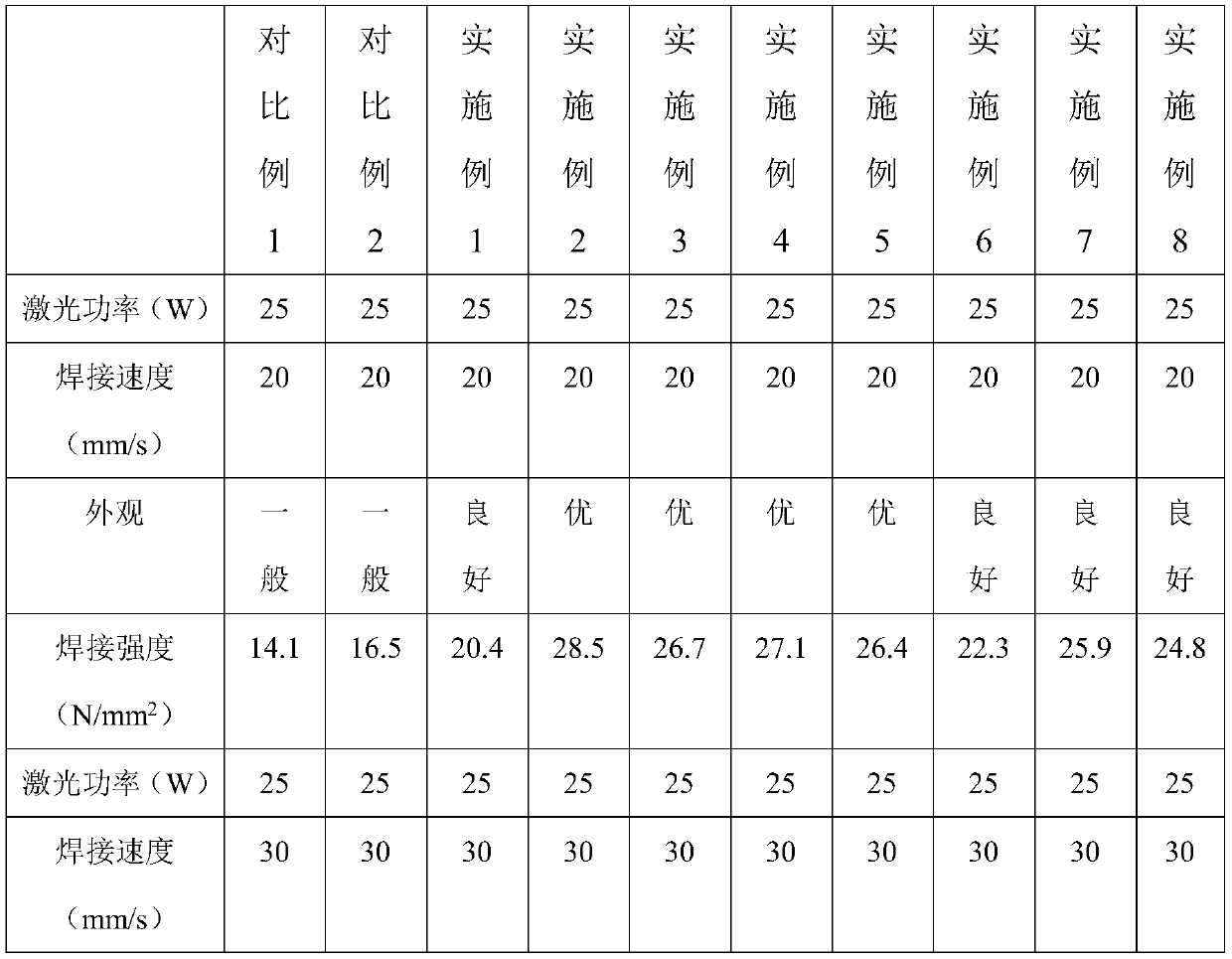

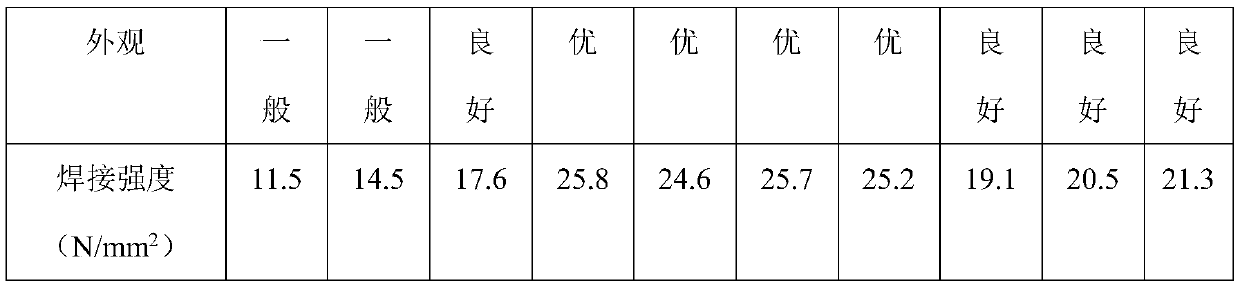

Examples

Embodiment 1

[0034] A preparation method for laser welding easy-to-process ABS composition, comprising the following steps:

[0035] (1) 99 parts of ABS resin (melt index is 15g / 10min), 1 part of reversible reaction crosslinking agent, 1 part of nano-indium tin oxide, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168 and lubricant silicone oil 0.1 Parts are added to a mixing mixer for pre-mixing, wherein, in the reversible reaction crosslinking agent, copolymer A is polymethyl methacrylate with side groups containing furan functional groups, and copolymer B is polystyrene with side groups containing maleimide , the mol ratio of the side group furan in the copolymer A and the side group maleimide in the copolymer B is 1:1, the control mixer speed is 100r / min, and the mixing time is 5min;

[0036] (2) The mixture obtained in step (1) is melted, blended, extruded and granulated by a twin-screw extruder, and the extrusion temperature is controlled to be 210-250°C, the screw speed is 30...

Embodiment 2

[0038] A preparation method for laser welding easy-to-process ABS composition, comprising the following steps:

[0039] (1) 80 parts of ABS resin (melt index is 15g / 10min), 20 parts of reversible reaction crosslinking agent, 0.5 part of nano-indium tin oxide, 0.1 part of antioxidant 1076, 0.1 part of antioxidant 618 and 0.1 part of lubricant silicone oil Parts are added to a mixing mixer for pre-mixing, wherein, in the reversible reaction crosslinking agent, copolymer A is an ethylene-methyl methacrylate copolymer containing furan functional groups in side groups, and copolymer B is a ethylene-methyl methacrylate copolymer containing maleimide in side groups. Styrene-acrylonitrile copolymer, the molar ratio of the side group furan in the copolymer A and the side group maleimide in the copolymer B is 2:1, the control mixer speed is 100r / min, and the mixing time is 20min;

[0040] (2) Melt, blend, extrude and granulate the mixture obtained in step (1) through a twin-screw extruder...

Embodiment 3

[0042] A preparation method for laser welding easy-to-process ABS composition, comprising the following steps:

[0043] (1) 85 parts of ABS resin (melt index is 25g / 10min), 15 parts of reversible reaction crosslinking agent, 0.4 part of nano-indium tin oxide, 0.2 part of antioxidant 1098, 0.3 part of antioxidant 618 and lubricant silicone oil 1 Parts are added to a mixing mixer for pre-mixing, wherein the copolymer A in the reversible reaction crosslinking agent is the ethylene-methyl methacrylate copolymer and polymethyl methacrylate blend (ethylene-methyl methacrylate) containing furan functional groups in the side group. The mass ratio of methyl acrylate copolymer to polymethyl methacrylate is 1:1), copolymer B is a styrene-acrylonitrile-maleic anhydride copolymer containing maleimide in the side group, and in copolymer A The mol ratio of the side group furan and the side group maleimide in the copolymer B is 3:1, the control mixer speed is 250r / min, and the mixing time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com