ABS composition for improving ultrasonic welding strength, and preparation method thereof

An ultrasonic welding and composition technology, which is applied in the field of polymer modified materials, can solve problems such as affecting the processing and forming properties of materials, and achieve the effects of broadening applications, ensuring welding strength, and improving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

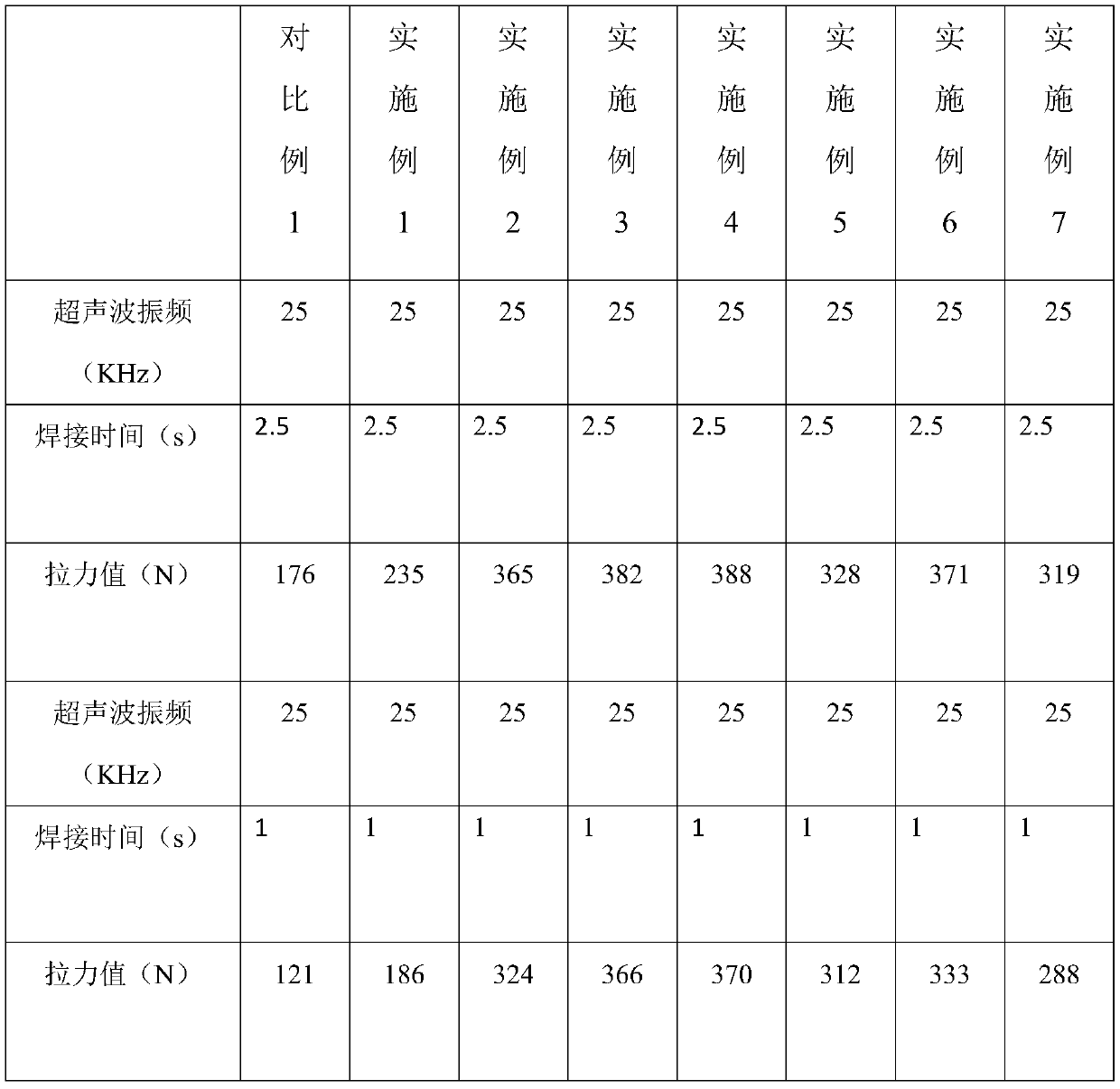

Examples

Embodiment 1

[0026] An ABS composition for improving ultrasonic welding strength and a preparation method thereof, comprising the following steps:

[0027] (1) Add 99 parts of ABS resin (melt index is 15g / 10min), 1 part of reversible reaction cross-linking agent, 10100.1 parts of antioxidant and 0.1 part of antioxidant 168 into a mixing mixer for pre-mixing, wherein, reversible reaction cross-linking agent Copolymer A in the joint agent is polymethyl methacrylate with side group containing furan functional group, copolymer B is polystyrene with side group containing maleimide, side group furan in copolymer A and side group in copolymer B The mol ratio of base maleimide is 1:1, and the control mixer rotating speed is 100r / min, and mixing time 5min;

[0028] (2) The mixture obtained in step (1) is melted, blended, extruded and granulated by a twin-screw extruder, and the extrusion temperature is controlled to be 210-250°C, the screw speed is 300r / min, and the vacuum degree is -0.06MPa, The ...

Embodiment 2

[0030] An ABS composition for improving ultrasonic welding strength and a preparation method thereof, comprising the following steps:

[0031] (1) Add 90 parts of ABS resin (melt index is 15g / 10min), 10 parts of reversible reaction cross-linking agent, 10100.1 parts of antioxidant and 0.1 part of antioxidant 168 into a mixing mixer for pre-mixing, wherein, reversible reaction cross-linking agent Copolymer A in the joint agent is polymethyl methacrylate with side group containing furan functional group, copolymer B is polystyrene with side group containing maleimide, side group furan in copolymer A and side group in copolymer B The mol ratio of base maleimide is 1:1, and the control mixer rotating speed is 100r / min, and mixing time 5min;

[0032] (2) The mixture obtained in step (1) is melted, blended, extruded and granulated by a twin-screw extruder, and the extrusion temperature is controlled to be 210-250°C, the screw speed is 300r / min, and the vacuum degree is -0.06MPa, Th...

Embodiment 3

[0034] An ABS composition for improving ultrasonic welding strength and a preparation method thereof, comprising the following steps:

[0035] (1) Add 80 parts of ABS resin (melt index is 5g / 10min), 20 parts of reversible reaction cross-linking agent, 10760.5 parts of antioxidant and 0.5 part of antioxidant 618 into a mixing mixer for pre-mixing, wherein, reversible reaction cross-linking agent In the joint agent, copolymer A is methyl methacrylate-butadiene-styrene copolymer containing furan functional group in side group, and copolymer B is styrene-maleic anhydride copolymer containing maleimide in side group, The molar ratio of the side group furan in the copolymer A to the side group maleimide in the copolymer B is 6:1, the control mixer speed is 300r / min, and the mixing time is 20min;

[0036] (2) Melt, blend, extrude and granulate the mixture obtained in step (1) through a twin-screw extruder, controlling the extrusion temperature to be 210-250°C, the screw speed to be 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com