Preparation method of polypyrrole graphite-phase carbon nitride composite material for treating uranium-containing wastewater through photocatalytic reduction and application thereof

A technology of graphite phase carbon nitride and composite materials, which is applied in the fields of reduced water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc., can solve the problem of small specific surface area, high electron-hole recombination rate and low light response Application range and other issues, to achieve good photocatalytic performance, avoid cumbersome processing, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

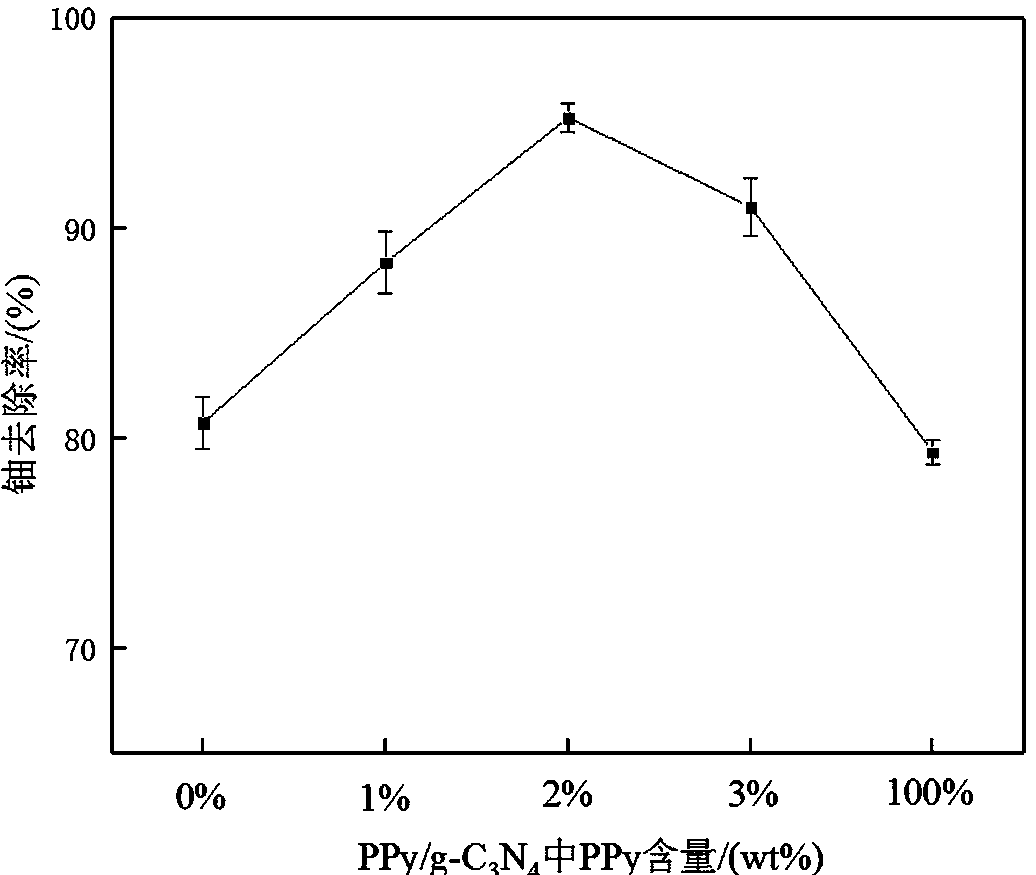

[0026] Embodiment 1, the preparation method of polypyrrole graphite phase carbon nitride composite material for photocatalytic reduction treatment of uranium-containing wastewater, comprising the following steps:

[0027] A. Weigh 20g of melamine, place it in a muffle furnace, and evenly raise it to 500°C at 2°C / min. After calcination for 4 hours, take out the yellow solid in the crucible to obtain graphite phase carbon nitride.

[0028] B, take by weighing sodium dodecylbenzenesulfonate and graphite phase carbon nitride according to the mass ratio of 1:18 and put it into the reactor, then add deionized water, place it in an ultrasonic oscillator and vibrate for 30min to obtain the first A mixed solution; wherein the mass ratio of sodium dodecylbenzenesulfonate to deionized water is 1g: 45ml.

[0029] C. Stir the first mixed solution in an environment of 0°C, and add pyrrole while stirring to obtain the second mixed solution, in which the mass of pyrrole and graphite phase car...

Embodiment 2

[0032] Embodiment 2, the preparation method of polypyrrole graphite phase carbon nitride composite material for photocatalytic reduction treatment of uranium-containing wastewater, comprising the following steps:

[0033] A. Weigh 23g of melamine, place it in a muffle furnace, and evenly raise it to 530°C at 3°C / min, and take out the yellow solid in the crucible after calcining for 3.5 hours to obtain graphite phase carbon nitride.

[0034] B, take by weighing sodium dodecylbenzenesulfonate and graphite phase carbon nitride according to the mass ratio of 1:19 and put it into the reactor, then add deionized water, place it in an ultrasonic oscillator and vibrate for 40min to obtain the first A mixed solution; wherein the mass ratio of sodium dodecylbenzenesulfonate to deionized water is 1g:48ml.

[0035] C. Stir the first mixed solution in an environment of 0°C, and add pyrrole while stirring to obtain the second mixed solution, in which the mass of pyrrole and graphite phase c...

Embodiment 3

[0038] Embodiment 3, the preparation method of polypyrrole graphite phase carbon nitride composite material for photocatalytic reduction treatment of uranium-containing wastewater, comprising the following steps:

[0039] A. Weigh 25g of melamine, place it in a muffle furnace, and evenly raise it to 550°C at 5°C / min, and take out the yellow solid in the crucible after calcining for 3 hours to obtain graphite phase carbon nitride.

[0040] B, take by weighing sodium dodecylbenzenesulfonate and graphite phase carbon nitride according to the mass ratio of 1:20 and put it into the reactor, then add deionized water, place it in an ultrasonic oscillator and vibrate for 50min to obtain the first A mixed solution; wherein the mass ratio of sodium dodecylbenzenesulfonate to deionized water is 1g: 50ml.

[0041] C. Stir the first mixed solution in an environment of 0°C, and add pyrrole while stirring to obtain the second mixed solution, in which the mass of pyrrole and graphite phase ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com