Production method and production line of whole-body large-particle stone-like ceramic thick plate

A large particle and production line technology, which is applied in the production of ceramic materials, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of easy cracking of the green body, cracking of the green body, and cracking of the production particles, so as to reduce the number of cracked particles and ensure The quality of the finished product and the effect of avoiding excessive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below through specific embodiments.

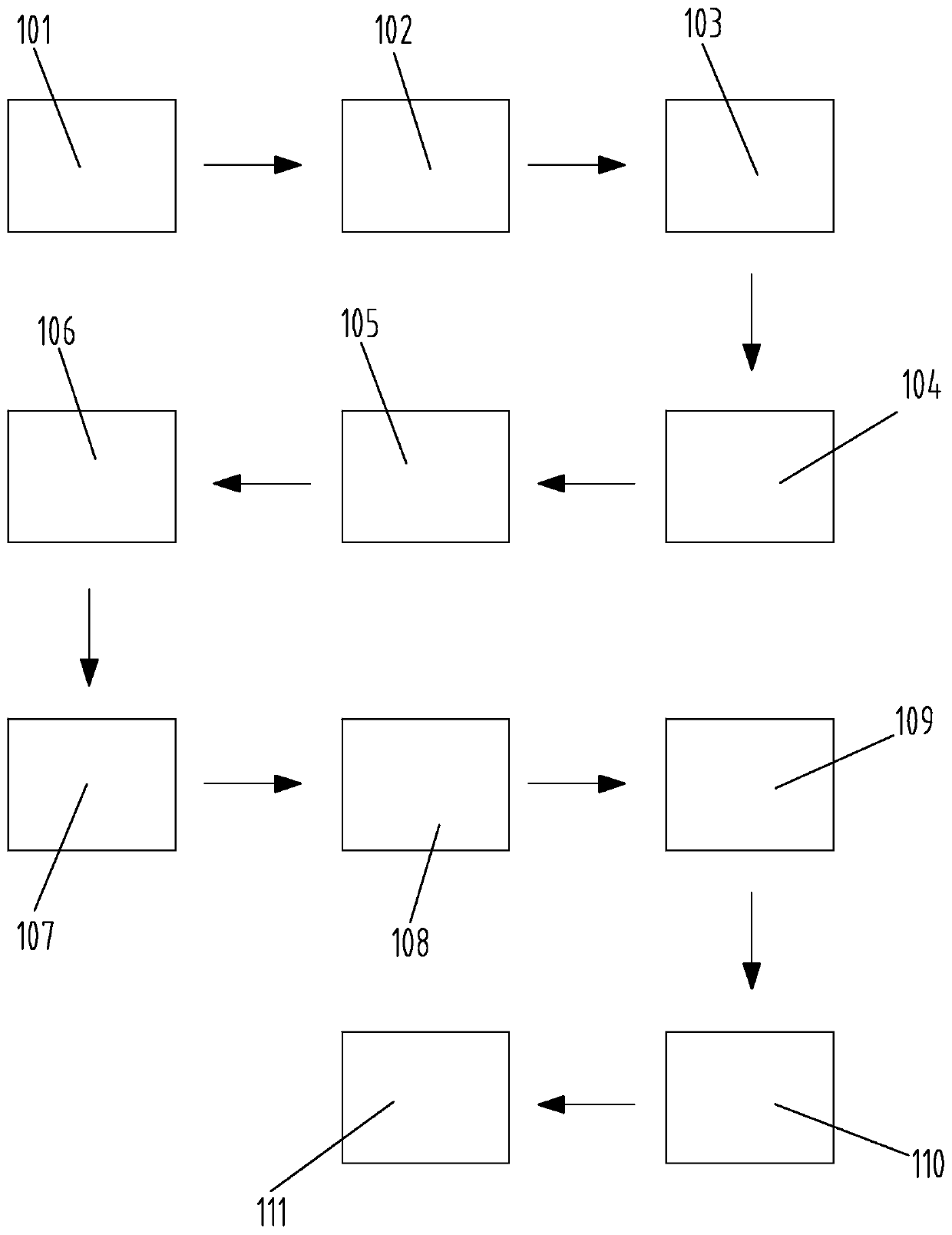

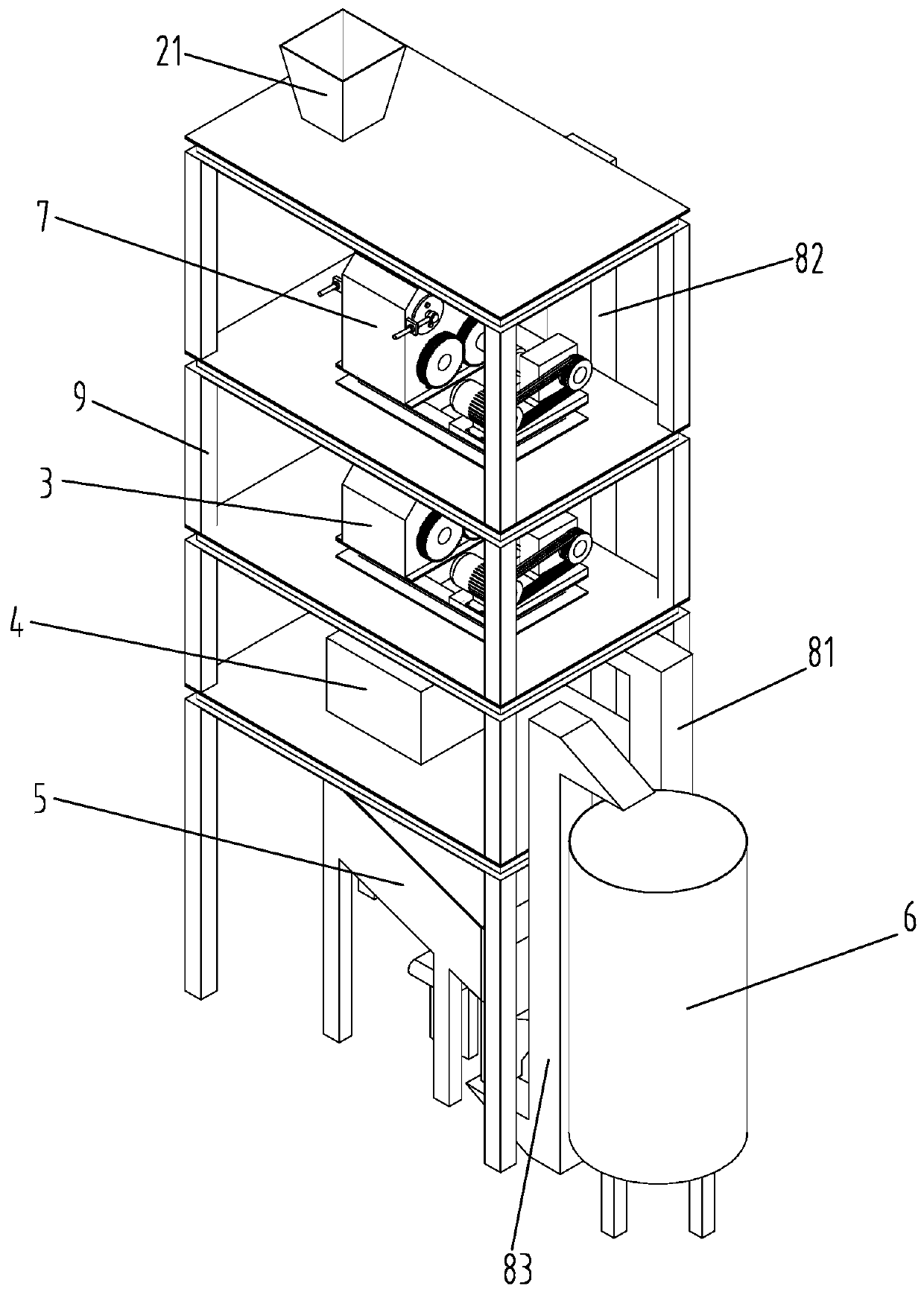

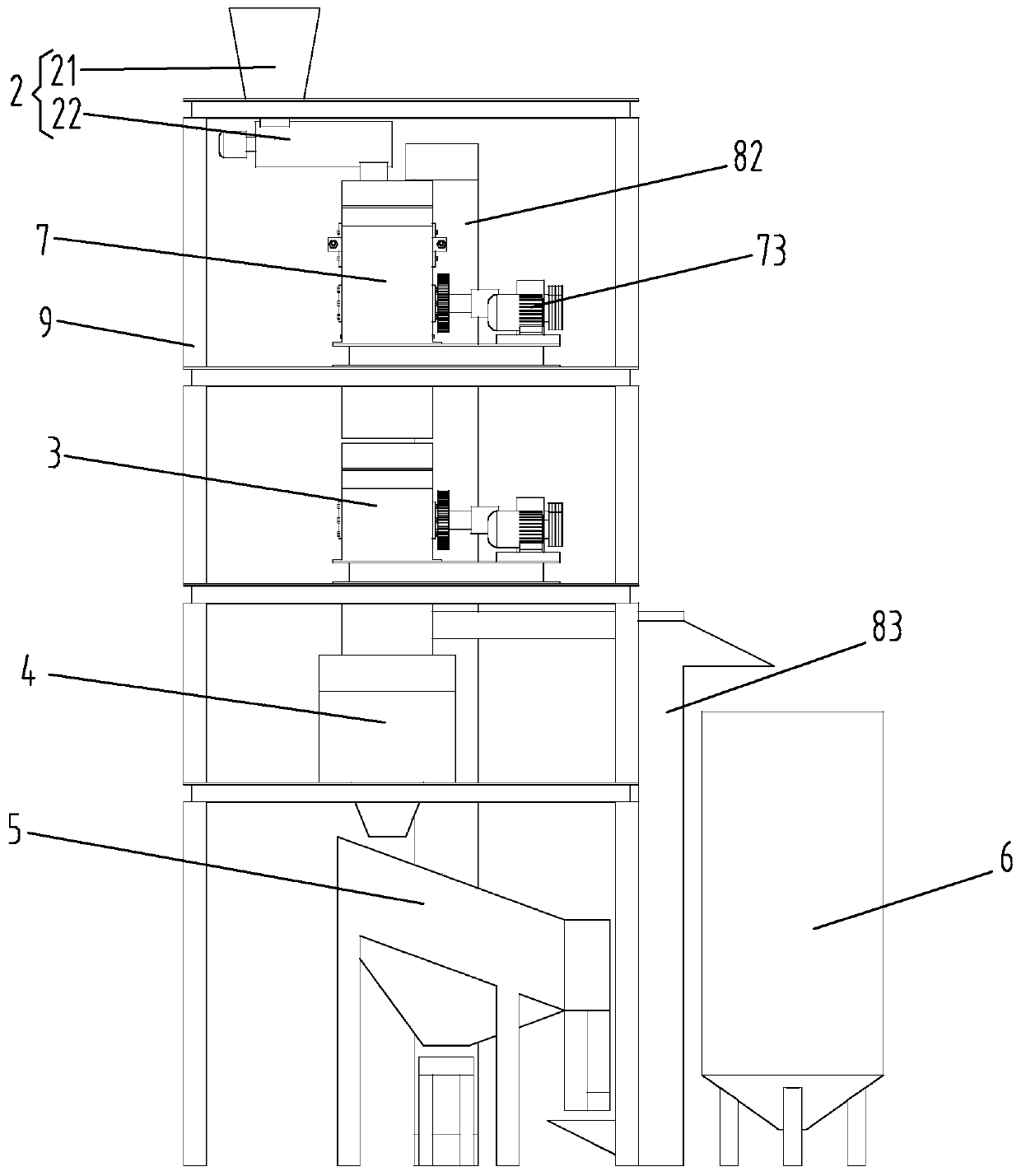

[0034] A large-grain imitation stone ceramic thick plate, the processing technology of which is as follows:

[0035] Step 1, batching, the weight components of the raw material of the large-grain imitation stone ceramic slab are as follows: 3-6 parts of Zhangpu clay, 5-10 parts of Zhangpu gray soil, 5-10 parts of washed soil, 2 parts of Zhangzhou ball soil -5 parts, 2-5 parts of magnesia soil, 5-10 parts of bentonite, 5-10 parts of potassium sand, 2-5 parts of wollastonite, 5-10 parts of Yongtai weathered fossil, 15-20 parts of Rongqiao sand, Hua'an 5-10 parts of stone rice, 15-20 parts of washed sand, 2-5 parts of pyrophyllite, 5-10 parts of high alumina stone, 2-5 parts of cooked porcelain powder, optimized, 5 parts of Zhangpu clay, 8 parts of Zhangpu lime soil , 9 parts of washed soil, 4 parts of Zhangzhou ball soil, 3 parts of magnesia soil, 8 parts of bentonite, 9 parts of potass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com