Aluminum-silicon-magnesium casting alloy mechanical property improving method

A technology for casting alloys and magnesium alloys, which is applied in the field of improving the mechanical properties of aluminum-silicon-magnesium casting alloys, and can solve the problems of high raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A ZL101 aluminum alloy melt is selected, and the silicon content is 7.06wt%. The iron content is 0.09 wt%. Other elements meet the alloy composition requirements. When the melt temperature is 750°C, add aluminum-lanthanum master alloy (the content of lanthanum is 10-20wt%) and aluminum-erbium master alloy (the content of erbium is 10-20wt%), the addition of lanthanum and erbium is respectively molten 0.25wt% and 0.05wt% of body weight. The melt was stirred and refined with nitrogen for 15 minutes. When the melt temperature is 690 ° C, it is quickly injected into the metal cavity, and the thickness of the casting is 10 mm. The metal mold is cooled by air, and the casting is water-cooled after demoulding. The water-cooled casting is kept at 515°C for 6 hours, cooled in 80-100°C water, and then cooled at 180°C for 12 hours. The tensile strength of the obtained alloy is 316MPa, the elongation is 11.6%, and the hardness is 82HB; the scanning electron microscope shows f...

Embodiment 2

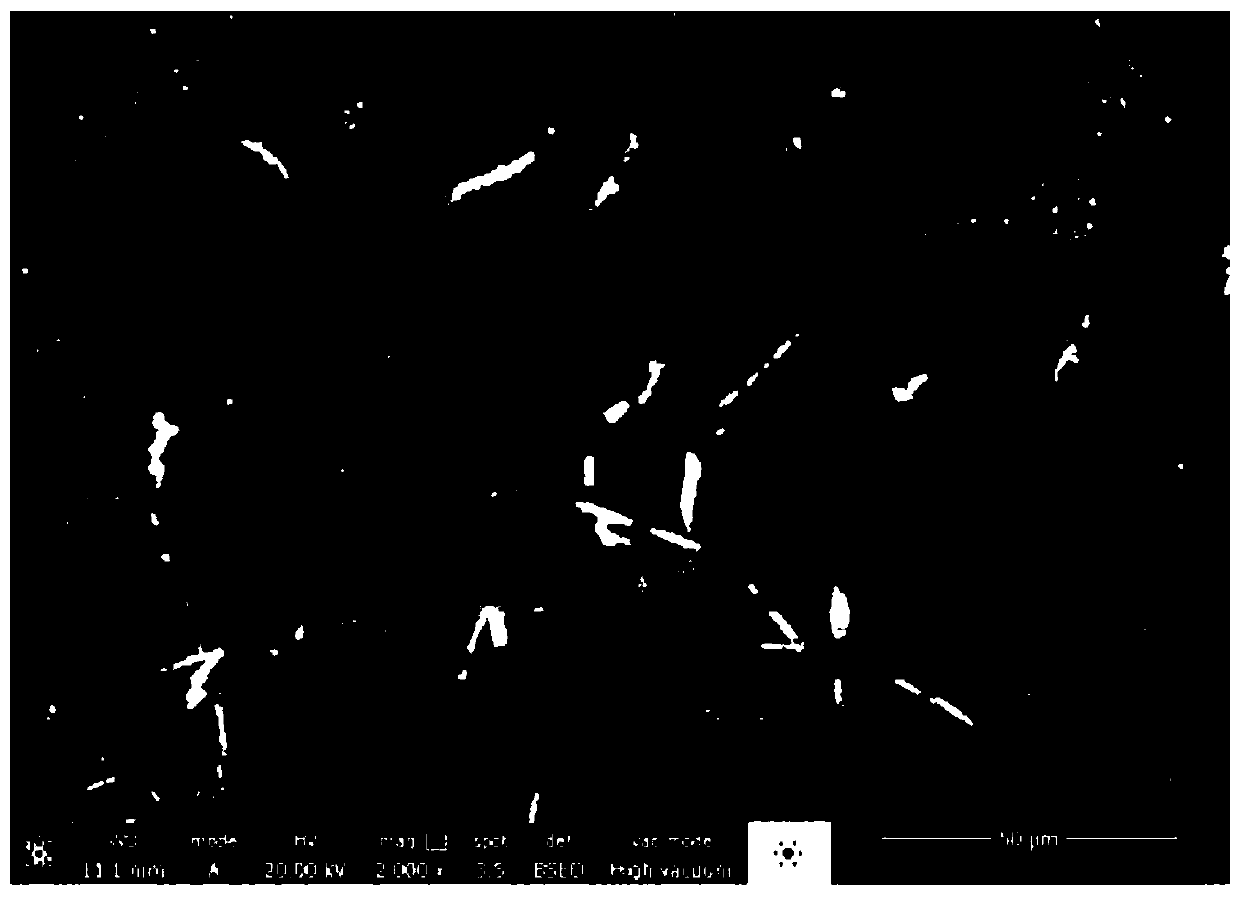

[0039] A ZL101 aluminum alloy melt is selected, and the silicon content is 7.12wt%. The iron content is 0.15 wt%. Other elements meet the alloy composition requirements. When the melt temperature is 760° C., cerium chloride and aluminum-holmium master alloy (the content of holmium is 10-20 wt %) are added, and the cerium chloride is baked for 24 hours before adding. The addition amounts of cerium and holmium are respectively 0.34wt% and 0.15wt% of the melt weight. The melt was stirred and refined with nitrogen for 10 minutes. When the melt temperature is 720 ° C, it is quickly injected into the metal cavity, and the thickness of the casting is 10 mm. The metal mold is cooled by air, and the casting is water-cooled after demoulding. The water-cooled casting is kept at 515°C for 8 hours, cooled in 80-100°C water, and then cooled at 180°C for 15 hours. The tensile strength of the obtained alloy is 280MPa, the elongation is 8.5%, and the hardness is 88HB; the scanning electro...

Embodiment 3

[0041] A ZL101 aluminum alloy melt is selected, and the silicon content is 7.10wt%. The iron content is 0.12 wt%. Other elements meet the alloy composition requirements. When the melt temperature was 740°C, a mixture of yttrium chloride and gadolinium fluoride was added, and the yttrium chloride and gadolinium fluoride were baked for 24 hours before addition. The addition amounts of yttrium and gadolinium are 0.30wt% and 0.15wt% of the melt weight, respectively. The melt was stirred and refined with nitrogen for 10 minutes. When the melt temperature is 700 ° C, it is quickly injected into the metal cavity, and the thickness of the casting is 10 mm. The metal mold is cooled by air, and the casting is water-cooled after demoulding. The water-cooled casting is kept at 515°C for 6 hours, cooled in 80-100°C water, and then cooled at 180°C for 10 hours. The tensile strength of the obtained alloy is 286MPa, the elongation is 8.6%, and the hardness is 85HB; the scanning electron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com