Laser-clad welding high-entropy alloy AlCoCrFeNi/27SiMn steel composite layer and preparing method thereof

A high-entropy alloy and laser cladding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high cost, long cycle, and increased suspended particles, and achieve low self-corrosion current density and surface shaping Good, excellent wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] A method for preparing a high-entropy alloy AlCoCrFeNi / 27SiMn steel composite layer by laser cladding welding, comprising the following steps:

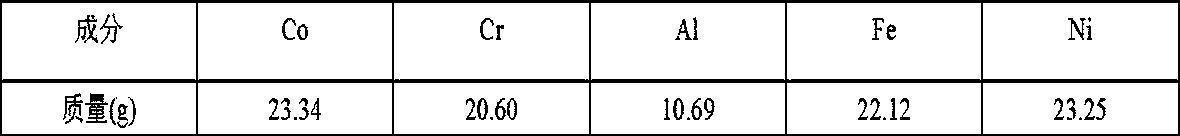

[0025] Step 1: Select the granular bulk metal with a purity of 99.99 wt. %. According to the atomic ratio of the alloy design, the total mass of the alloy is 100 g as the standard, and the processed metal particles of each element are selected as raw materials. The use accuracy can reach 4 decimal places The analytical balance weighs the required mass of each element in turn, and the specific mass is shown in Table 1;

[0026] Table 1 Composition of high entropy alloy AlCoCrFeNi

[0027]

[0028] After the raw materials are put into the crucible, keep the vacuum arc melting furnace airtight, use a mechanical pump to pre-evacuate to 20 Pa, and then use a molecular pump to evacuate the furnace until the pressure in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com