Flexible energy storage film and its preparation method, film capacitor

An energy storage and thin film technology, applied in the energy field, can solve the problems of insufficient flexibility of energy storage thin films, and achieve the effect of high reliability, high reliability and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

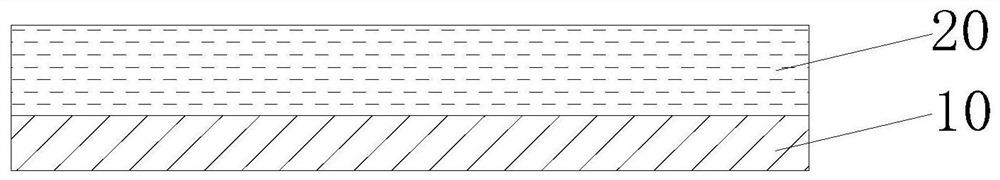

[0036] The preparation method of the flexible energy storage film provided by the present invention comprises:

[0037] S1, providing a flexible metal substrate;

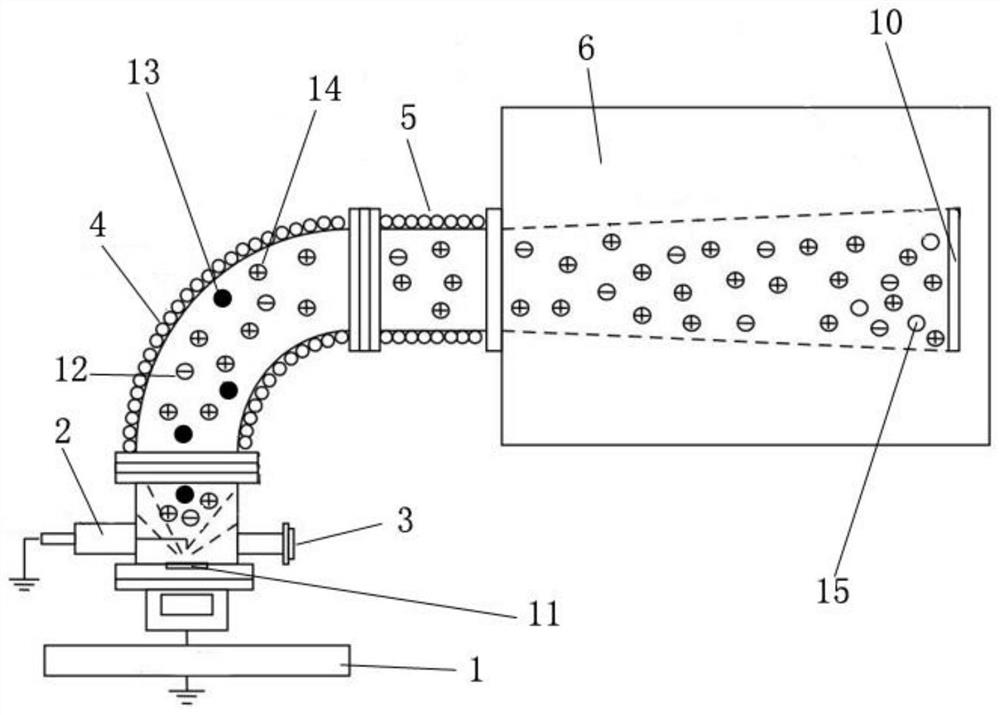

[0038] S2, using titanium metal as the target material, depositing a titanium dioxide prefabricated layer on the flexible metal substrate by using the magnetic filter multi-arc ion plating method, wherein the working atmosphere in the magnetic filter multi-arc ion plating method is argon and oxygen mixed gas;

[0039] S3, performing heat treatment on the flexible metal substrate deposited with the titanium dioxide prefabricated layer to obtain a flexible energy storage film.

[0040] In step S1, the material of the flexible metal substrate is not limited, as long as it has good flexibility, strong high-temperature oxidation resistance, electrical conductivity, and does not react with the titanium dioxide ceramic film, including copper foil, titanium foil, silver foil, One of gold foil, platinum foil, aluminum foil...

Embodiment 1

[0075] With flexible electrolytic copper foil as the substrate, the thickness is 18 μm, the surface roughness is 0.8 μm, it is placed in a vacuum chamber, and the vacuum is evacuated to 3×10 -3 Pa. The vacuum chamber is heated to 150°C, the holding time is 10min, filled with argon, the flow rate of argon is 20sccm, and the vacuum degree of the vacuum chamber is 2×10 -2 Pa, turn on the Hall ion source, set the voltage of the Hall ion source to 1000V, the current to 0.5A, and treat for 1min to make the surface tension of the copper foil reach 60 dynes.

[0076] Maintain a vacuum of 2.0×10 -2 Pa, the argon gas flow rate is 18 sccm, turn on the oxygen, make the oxygen flow rate 2 sccm, turn on the magnetic filter multi-arc ion plating power supply, adjust the arc current to 50A, draw the current to 9A, and apply a bias voltage of 5V to the flexible electrolytic copper foil. The metal is used as the target material, and the deposition time is 1min to form a titanium dioxide layer...

Embodiment 2

[0081]With flexible silver foil as the substrate, the thickness of the silver foil is 12 μm, the surface roughness is 0.5 μm, placed in a vacuum chamber, and vacuumed to 3×10 -3 Pa. The vacuum chamber is heated to 100°C, the holding time is 20min, filled with argon, the flow rate of argon is 30sccm, and the vacuum degree of the vacuum chamber is 3×10 -2 Pa, turn on the Hall ion source, set the voltage of the Hall ion source to 800V, and the current to 0.6A, and treat for 5min to make the surface tension of the copper foil reach 65 dynes.

[0082] Maintain a vacuum of 3.0×10 -2 Pa, the argon gas flow rate is 25 sccm, turn on the oxygen, make the oxygen flow rate 5 sccm, turn on the magnetic filter multi-arc ion plating power supply, adjust the arc current to 55A, draw the current to 10A, and apply a bias voltage of 6V to the flexible silver foil. As a target, a titanium dioxide layer with a thickness of 400 nm and a grain size of 80 nm was formed on the copper foil with a dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com