Preparing method for high-heat-conduction copper-based brake pad with orientation structure

A brake pad, high thermal conductivity technology, applied in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve the problems of poor thermal conductivity, poor bonding force, interface defects and other problems of copper-based brake pads, so as to improve mechanical performance, Interfacial forces increase, reduce defects and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

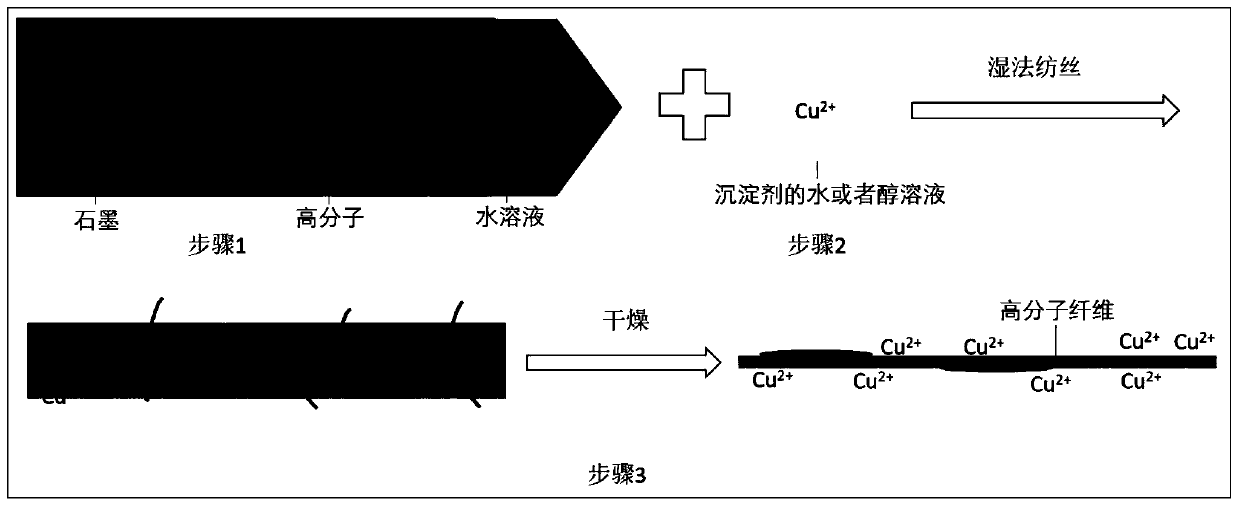

[0044] In this embodiment, the preparation method of the high thermal conductivity copper-based brake pad with an orientation structure is as follows:

[0045] (1) 18wt% of flake graphite, 3wt% of sodium carboxymethyl cellulose, and 79wt% of water were mixed uniformly, and ultrasonically dispersed after stirring;

[0046] (2) prepare the copper sulfate aqueous solution of concentration 2wt%;

[0047] (3) Using monofilament spinning equipment, the propulsion speed is 0.5ml / min, and the spinning solution in step 1 is precipitated in the coagulation solution in step 2 to prepare fibers;

[0048] (4) Dry the prepared fiber at room temperature after winding, and then place it in an oven at 80°C for 24 hours;

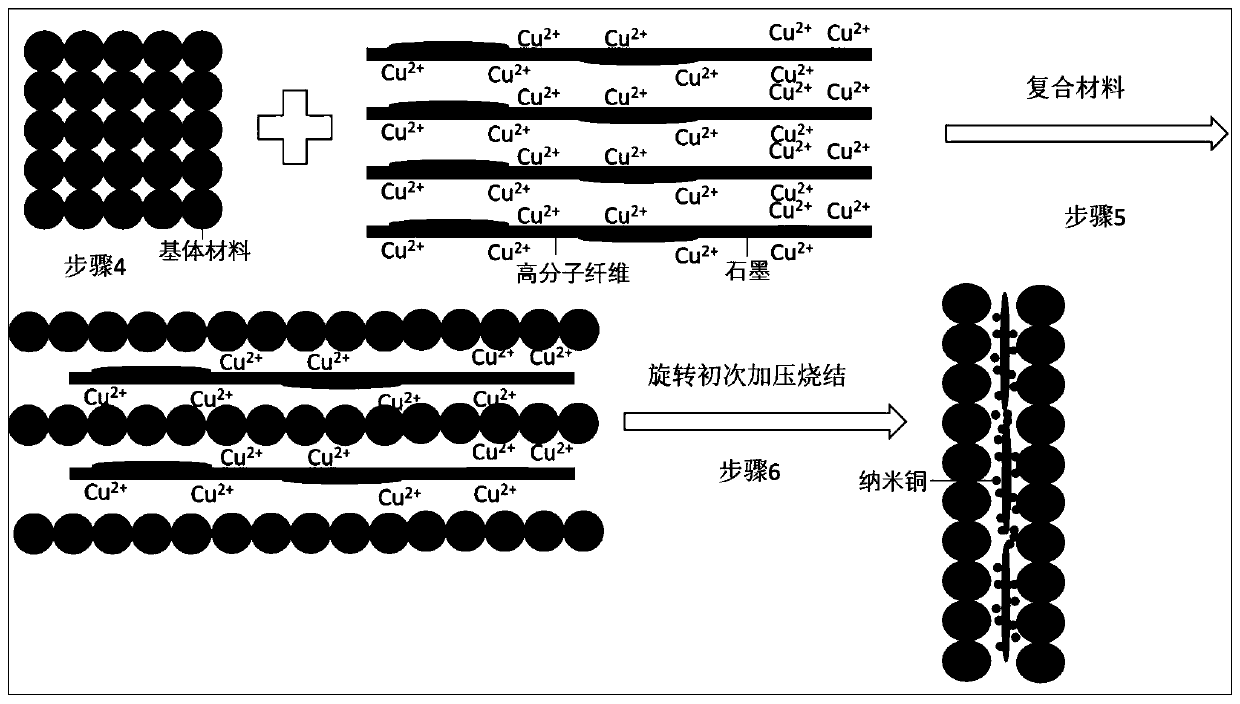

[0049] (5) The base material adopts 80wt% copper powder, 15wt% iron powder, 0.6wt% chromium powder, 1wt% nickel powder, 2wt% molybdenum disulfide, 1wt% silicon carbide, 0.4wt% glycerin, and mix them evenly Become a paste.

[0050] (6) Take 10wt% of fibers in step 4 and 90w...

Embodiment 2

[0056] In this embodiment, the preparation method of the high thermal conductivity copper-based brake pad with an orientation structure is as follows:

[0057] (1) 18wt% of flake graphite, 5wt% of polyvinylpyrrolidone, and 77wt% of water were mixed uniformly, and ultrasonically dispersed after stirring;

[0058] (2) prepare the copper acetate ethanol solution of concentration 5wt%;

[0059] (3) Using monofilament spinning equipment, the propulsion speed is 0.5ml / min, and the spinning solution in step 1 is precipitated in the coagulation solution in step 2 to prepare fibers;

[0060] (4) Dry the prepared fiber at room temperature after winding, and then place it in an oven at 80°C for 24 hours;

[0061] (5) The base material adopts 80wt% copper powder, 15wt% iron powder, 0.6wt% chromium powder, 1wt% nickel powder, 2wt% molybdenum disulfide, 1wt% silicon carbide, 0.4wt% glycerin, and mix them evenly Become a paste.

[0062] (6) Take 20wt% of fibers in step 4 and 80wt% of base...

Embodiment 3

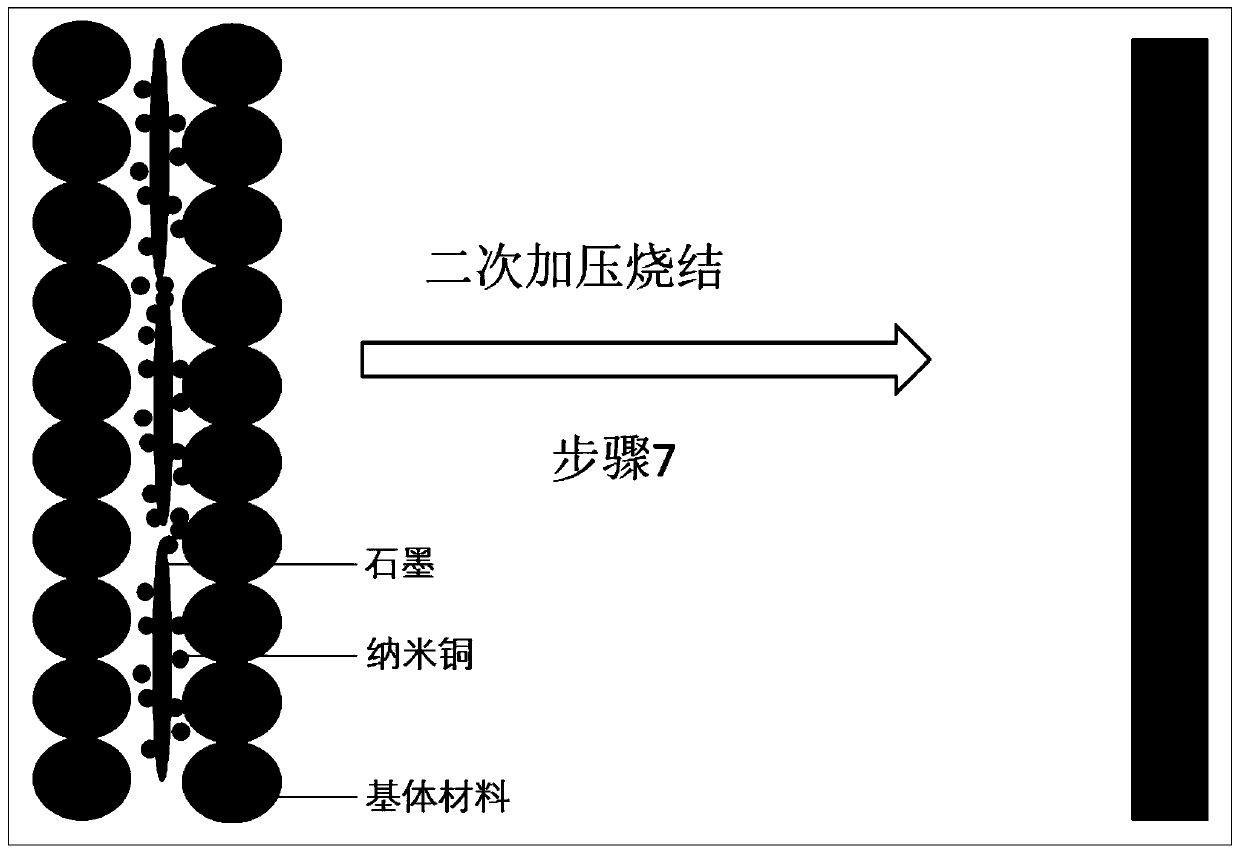

[0068] In this embodiment, the preparation method of the high thermal conductivity copper-based brake pad with an orientation structure is as follows:

[0069] (1) Mix 18wt% of flake graphite, 1wt% of dopamine hydrochloride, and 81wt% of water, and ultrasonically disperse after stirring;

[0070] (2) prepare the cupric nitrate ammonia solution of concentration 8wt%;

[0071] (3) Using monofilament spinning equipment, the propulsion speed is 0.5ml / min, and the spinning solution in step 1 is precipitated in the coagulation solution in step 2 to prepare fibers;

[0072] (4) Dry the prepared fiber at room temperature after winding, and then place it in an oven at 80°C for 24 hours;

[0073] (5) The base material adopts copper powder 85wt%, 10wt% iron powder, 1wt% chromium powder, 0.6wt% nickel powder, silicon dioxide 1wt%, aluminum oxide 2wt%, glycerin 0.4wt%, will Mix well to form a paste.

[0074] (6) Get 15wt% of fibers in step 4 and 85wt% of base paste in step 5, arrange th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com