Low-cost high-strength high-plasticity zirconium-based amorphous composite and preparation method thereof

A zirconium-based amorphous alloy and composite material technology, which is applied in the field of amorphous alloy composite materials, can solve the problems of poor room temperature plasticity and high raw material cost of zirconium-based amorphous alloys, and achieves expansion of practical application range, good repeatability, and process methods. and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

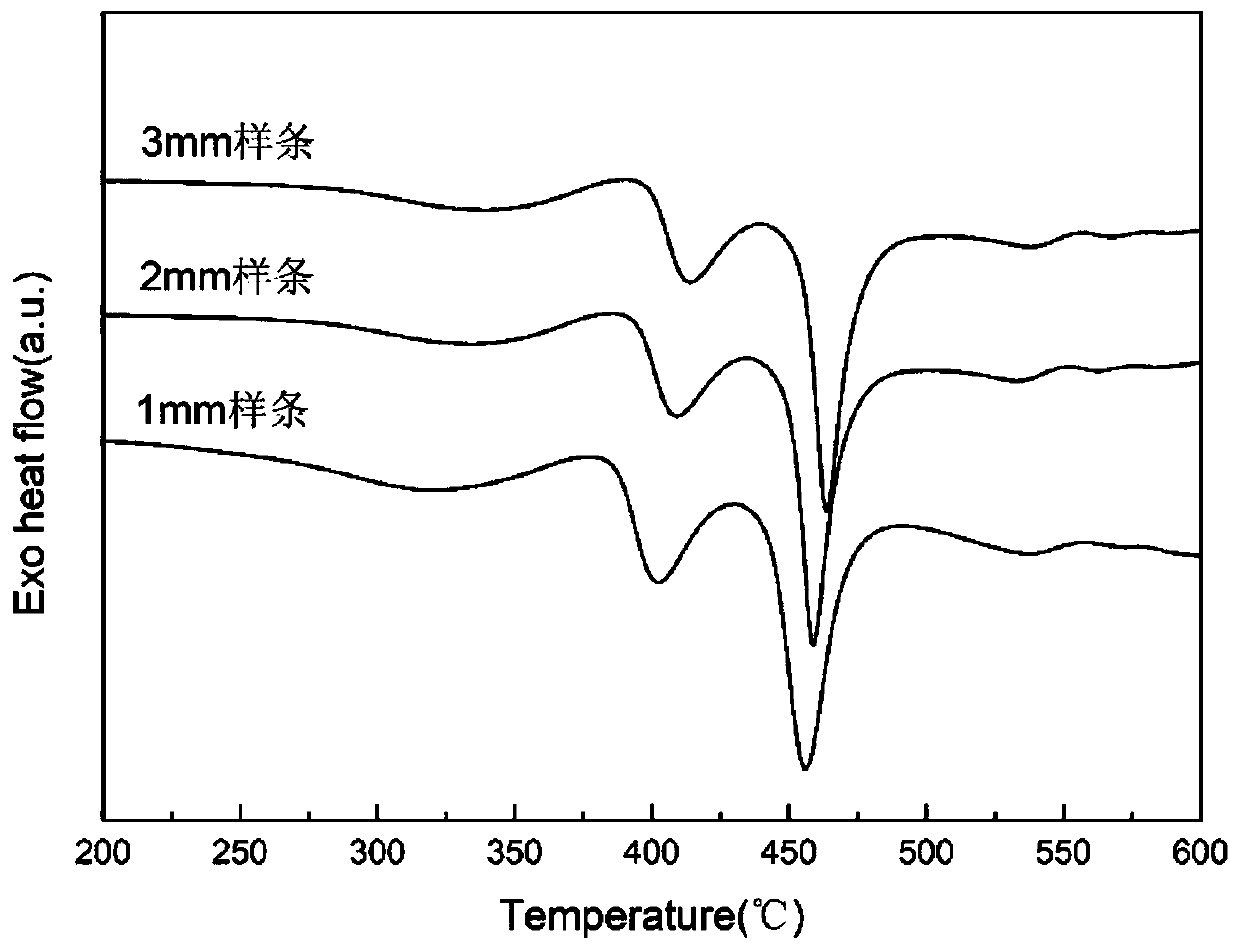

[0043] The chemical structural formula of the zirconium-based amorphous alloy composite material of the present invention is Zr 58.5 Ti 14.3 Nb 5.2 Cu 6.1 Ni 4.9 Be 11.0 , The preparation process is as figure 1 Shown:

[0044] (1-1) Ingredients: It is required that the purity of Zr, Ti, Nb, Cu, Ni, Be metal raw materials are all industrial purity, and each metal raw material needs to be pre-treated, that is, use coarse sandpaper to remove the surface oxide film, and then use Acetone and industrial alcohol are used for ultrasonic cleaning, and they are dried with a hair dryer. Zr 58.5 Ti 14.3 Nb 5.2 Cu 6.1 Ni 4.9 Be 11.0 After the atomic percentage of Zr, Ti, Nb, Cu, Ni, and Be is converted into weight percentage, the batching is carried out. For example, according to the weight of 90g of each master alloy ingot, the required quality of each metal raw material is accurately weighed by a precision electronic balance.

[0045] (1-2) Master alloy smelting: Under the protection of high-...

Embodiment 2

[0056] The chemical structural formula of the zirconium-based amorphous alloy composite material of the present invention is Zr 58.5 Ti 14.3 Nb 5.2 Cu 6.1 Ni 4.9 Be 11.0 , The preparation process is as figure 1 Shown:

[0057] (2-1) It is required that the purity of Zr, Ti, Nb, Cu, Ni, and Be metal raw materials are all industrial purity, and each metal raw material needs to be pre-treated, that is, use coarse sandpaper to remove the surface oxide film, and then use acetone and Ultrasonic cleaning with industrial alcohol and drying with a hair dryer. Zr 58.5 Ti 14.3 Nb 5.2 Cu 6.1 Ni 4.9 Be 11.0 After the atomic percentage of Zr, Ti, Nb, Cu, Ni, and Be is converted into weight percentage, the batching is carried out. For example, according to the weight of each master alloy ingot of 95g, the required quality of each metal raw material is accurately weighed by a precision electronic balance.

[0058] (2-2) Master alloy smelting: Under the protection of high-purity argon and Ti purifi...

Embodiment 3

[0069] The chemical structural formula of the zirconium-based amorphous alloy composite material of the present invention is Zr 58.5 Ti 14.3 Nb 5.2 Cu 6.1 Ni 4.9 Be 11.0 , The preparation process is as figure 1 Shown:

[0070] (3-1) It is required that the purity of Zr, Ti, Nb, Cu, Ni, Be metal raw materials are all industrial purity, and each metal raw material needs to be pre-treated, that is, use coarse sandpaper to remove the surface oxide film, and then use acetone and Ultrasonic cleaning with industrial alcohol and drying with a hair dryer. Zr 58.5 Ti 14.3 Nb 5.2 Cu 6.1 Ni 4.9 Be 11.0 After the atomic percentages of Zr, Ti, Nb, Cu, Ni, and Be are converted into weight percentages, ingredients are carried out. For example, according to the weight of 100g of each master alloy ingot, use a precision electronic balance to accurately weigh each metal raw material of the required quality.

[0071] (3-2) Master alloy smelting: Under the protection of high-purity argon and Ti purific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com