Method of forming TiB2 particle-reinforced high-entropy alloy coating on titanium alloy

A particle-enhanced, high-entropy alloy technology, applied in metal material coating process, coating, superimposed layer plating, etc., can solve the problems of blank technology and method, less research work, poor oxidation resistance, etc. The effect of improving hardness and oxidation resistance, improving wear resistance and oxidation resistance, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

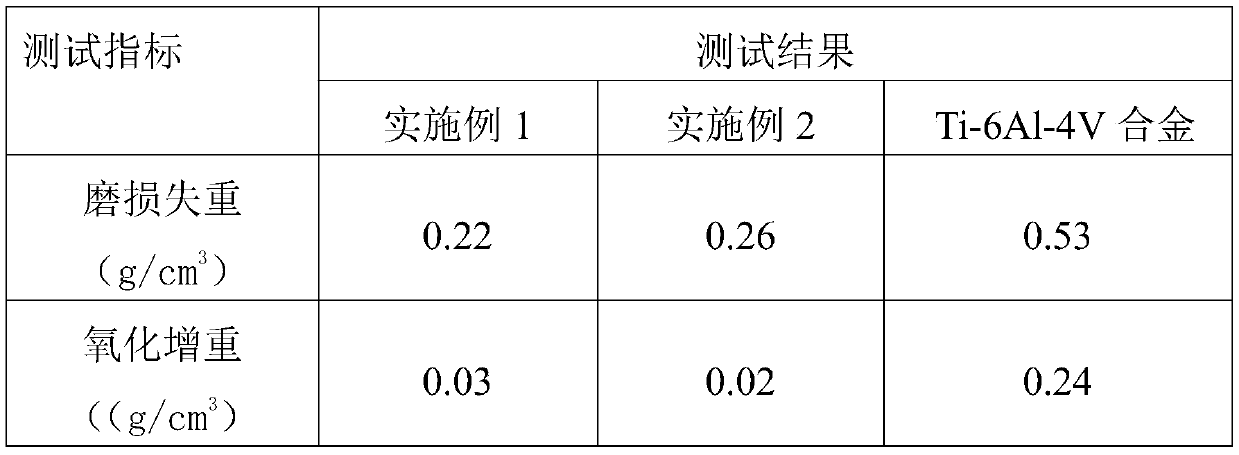

Examples

Embodiment 1

[0027] A Ti-6Al-4V alloy with a size of 150×100×10 mm was subjected to TiB 2 Particle Reinforced CoCrCuFeNiMoMn High Entropy Alloy Coating

[0028] Polish the surface of the base metal with 2500 mesh sandpaper, clean it with ultrasonic waves for 30 minutes, and then dry it in a resistance furnace at 40°C. Use magnetron sputtering equipment to first use Co as the target material, and coat a Co film on the Ti-6Al-4V alloy, with a thickness of Then use Ni as the target material to coat Ni film on the basis of Co film with a thickness of 35nm, and finally use Cr as the target material to plate Cr film on the basis of Co and Ni film with a thickness of 45nm. Co, Cr, Cu, Fe, Ni, Mo, Mn, TiB with a particle size of 25 microns 2 The powder is uniformly mixed by a ball mill, and the molar ratio of the mixed powder is Co:Cr:Cu:Fe:Ni:Mo:Mn:TiB 2 = 1:1:1:1:1:1:1:0.3. Add the mixed powder to the feeding system of the plasma cladding equipment, feed 99.9% argon gas, and spray the mixed p...

Embodiment 2

[0030] Industrial pure titanium (purity 99.7%) alloy with dimensions 180×100×15 mm for TiB 2 Particle Reinforced CoCrCuFeNiMoMn High Entropy Alloy Coating

[0031] The surface of the base metal was polished with 3000-grit sandpaper, cleaned ultrasonically for 30 minutes, and then dried in a resistance furnace at 30°C. Use magnetron sputtering equipment to first use Co as the target material, coat Co film on the alloy with a thickness of 70nm, then use Ni as the target material, coat Ni film on the basis of the Co film with a thickness of 70nm, and finally use Cr as the target Material, on the basis of Co and Ni film, Cr film is plated, the thickness is 70nm. Co, Cr, Cu, Fe, Ni, Mo, Mn, TiB with a particle size of 10 microns 2 The powder is uniformly mixed by a ball mill, and the molar ratio of the mixed powder is Co:Cr:Cu:Fe:Ni:Mo:Mn:TiB 2= 1:1:1:1:1:1:1:0.3. The mixed powder is added to the feeding system of the plasma cladding equipment, and 99.9% argon gas is introduced...

Embodiment 3

[0033] Industrial pure titanium (purity 99.9%) alloy with dimensions 180×100×25 mm for TiB 2 Particle Reinforced CoCrCuFeNiMoMn High Entropy Alloy Coating

[0034] The surface of the base metal was polished with 2000-grit sandpaper, cleaned by ultrasonic for 20 minutes, and then dried in a vacuum resistance furnace at 50°C. Use magnetron sputtering equipment to first use Co as the target material, coat a Co film on the alloy with a thickness of 10nm, then use Ni as the target material, coat a Ni film on the basis of the Co film with a thickness of 10nm, and finally use Cr as the target Material, on the basis of Co and Ni film, plate Cr film with a thickness of 10nm. Co, Cr, Cu, Fe, Ni, Mo, Mn, TiB with a particle size of 30 microns 2 The powder is uniformly mixed by a ball mill, and the molar ratio of the mixed powder is Co:Cr:Cu:Fe:Ni:Mo:Mn:TiB 2 = 1:1:1:1:1:1:1:0.3. The mixed powder is added to the feeding system of the plasma cladding equipment, and 99.9% argon gas is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com