Modification method for SnO2 electron selective transmission layer

A selective transmission and modification technology, applied in the field of solar cells, can solve the problems of not being suitable for flexibility requirements, increasing parasitic absorption loss, reducing transmittance, etc., to improve mobility and electron extraction ability, improve crystal quality and Stability and the effect of reducing energy level mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] in SnO 2 Add 7.4at% phosphoric acid (Sinopharm) to the sol (Alfa Aesar), 5000rpm, 30s homogeneous spin coating, dry at 100°C for 10min, anneal at 180°C for 30min in nitrogen. Thereafter spin-coated perovskite layer ((FAPbI 3 ) 0.85 (MAPbBr 3 ) 0.15 ), a hole transport layer (Spiro-OMeTAD), and a silver electrode with a thickness of 80 nm.

[0044] Fourier transform infrared spectroscopy analysis shows that phosphorus exists in the form of polyphosphate, such as figure 1 shown.

[0045] Testing monolayer SnO with a semiconductor parameter meter 2 The J-V curve of the film, the carrier mobility is calculated according to the Mott-Gurney law. It was found that after doping SnO with phosphoric acid 2 The electron mobility is changed from 1.70×10 -4 cm 2 V -1 the s -1 Increased to 5.08×10 -4 cm 2 V -1 the s -1 .

[0046] The main performance parameters of solar cells before and after doping are shown in the table below, which shows that the performance of th...

Embodiment 2

[0050] in SnO 2 Add 2at% ammonium sulfide (Sinopharm) to the sol (Alfa Aesar), 5000rpm, 30s spin coating, drying at 100°C for 10min, annealing at 180°C for 30min in nitrogen. Thereafter spin-coated perovskite layer ((FAPbI 3 ) 0.85 (MAPbBr 3 ) 0.15 ), a hole transport layer (Spiro-OMeTAD), and a silver electrode with a thickness of 80 nm.

[0051] Fourier transform infrared spectroscopy analysis showed that sulfur element combined with Sn atoms in the form of S-Sn, passivating SnO 2 surface, such as figure 2 shown.

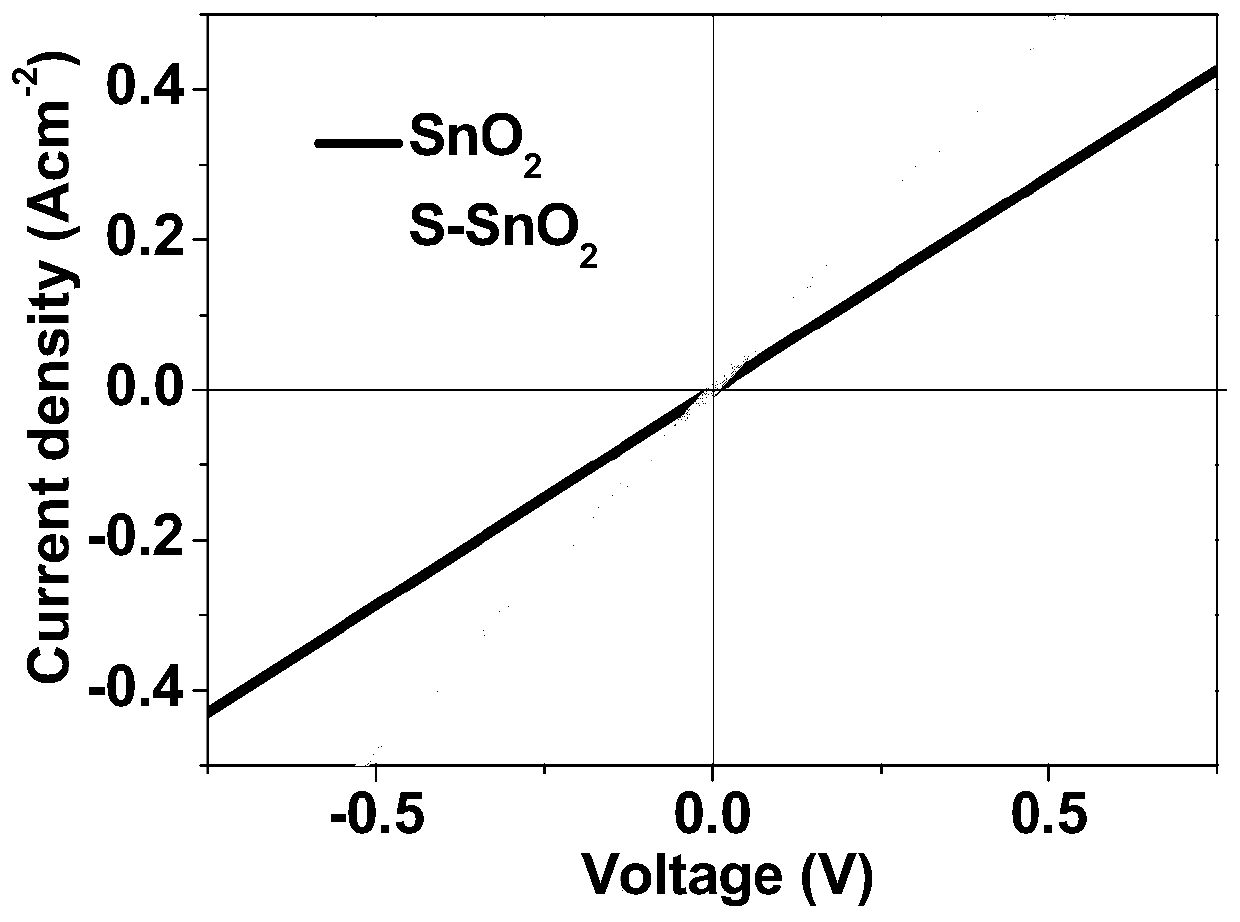

[0052] J-V curve analysis shows that the SnO after ammonium sulfide doping 2 The conductivity is greatly improved, such as image 3 shown.

[0053] The efficiency statistics of perovskite solar cells before and after doping are as follows: Figure 4 As shown, it can be clearly seen that the battery efficiency is greatly improved after doping with ammonium sulfide.

Embodiment 3

[0055] in SnO 2 Add 2at% taurine (Sinopharm) to the sol (Alfa Aesar), 5000rpm, 30s homogeneous spin coating, dry at 100°C for 10min, anneal at 180°C for 30min in nitrogen. Thereafter spin-coated perovskite layer ((FAPbI 3 ) 0.85 (MAPbBr 3 ) 0.15 ), a hole transport layer (Spiro-OMeTAD), and a silver electrode with a thickness of 80 nm.

[0056] The J-V curves of solar cells before and after doping are as follows: Figure 5 As shown, it can be seen that the short-circuit current density of the battery is significantly improved after doping with taurine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com