Simulating device and method for diameter change rule of gas extraction borehole

A technology of aperture change and gas drainage, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problem of weak resistance to damage, intensified creep deformation, and no simulation device for the variation law of drilling hole diameter. and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

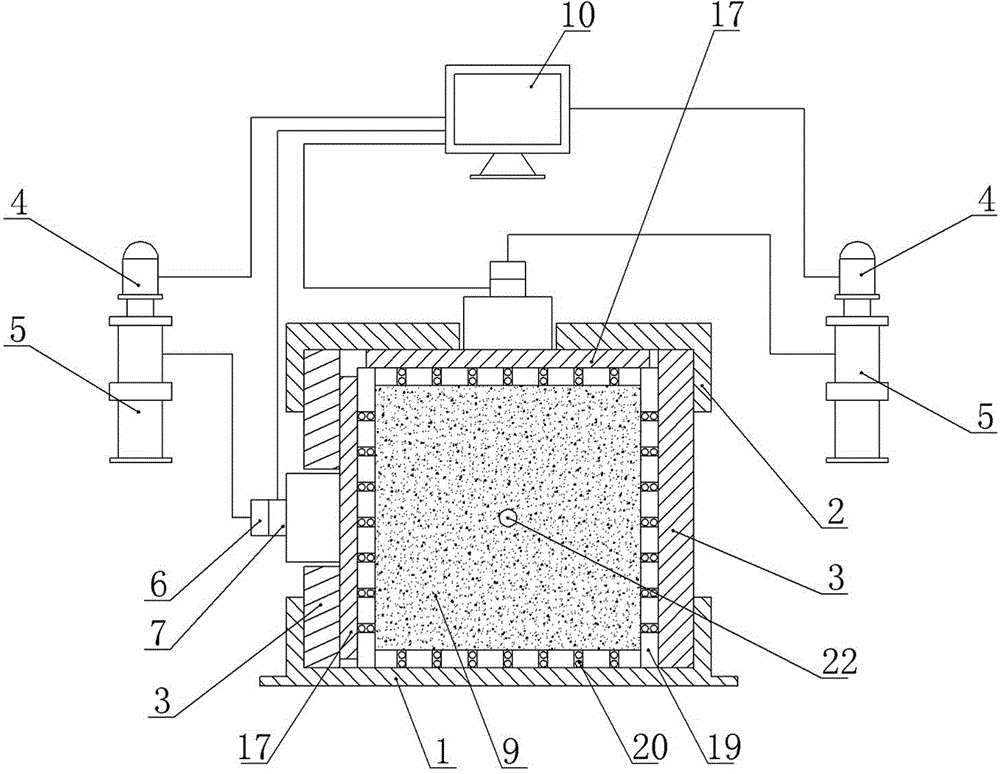

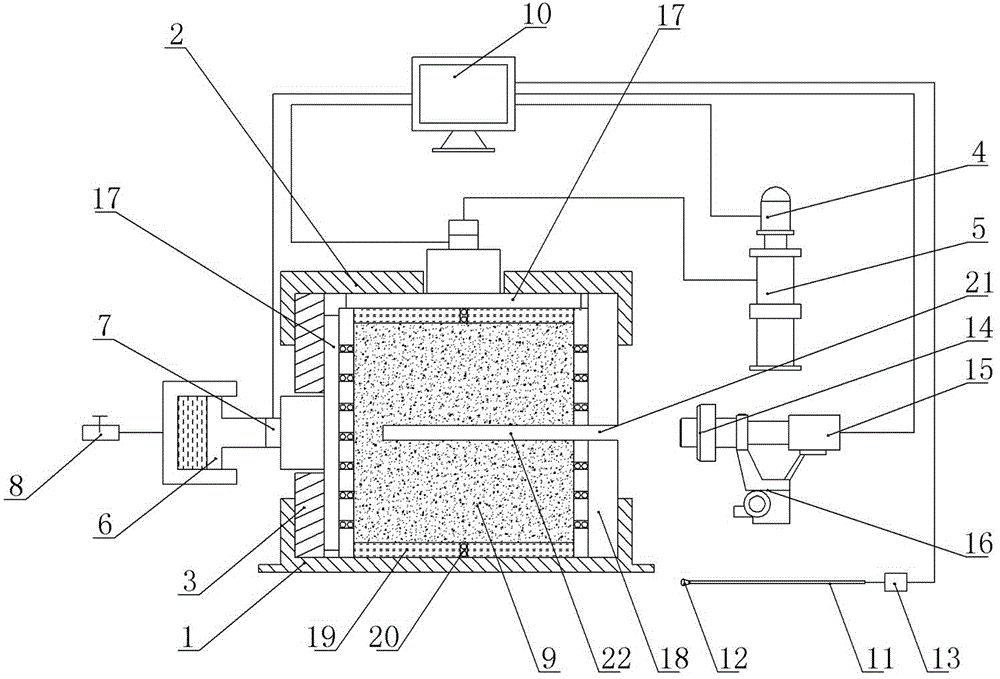

[0025] Embodiment one: see figure 1 , figure 2 , a device for simulating the change law of borehole diameter in coal seam gas drainage, comprising a true triaxial pressure test device, an optical borehole deformation observation device, a coal fracture evolution observation device and a host 10.

[0026] The true triaxial pressure test device includes a pressure cell for placing the coal body sample, three vertical pressurization mechanisms respectively arranged on the top, front and left sides of the pressure cell on three mutually perpendicular sides, and The observation hole 21 processed in the later stage on the side of the rear part of the box, when the vertical pressure mechanism applies a constant stress to the coal body sample, the corresponding observation hole 21 and pumping hole 21 are respectively opened on the side of the rear part of the pressure box and the coal body sample. Borehole 22 is used for simulated observation; the pressure box includes a base 1, an ...

Embodiment 2

[0029] Embodiment two: see figure 1 , figure 2 , the structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that: each side of the coal body sample is also provided with a stress conduction layer, and each side of the described The stress conduction layer on the top includes a plurality of aluminum plates 19 arranged in a matrix, and elastic rubber tubes 20 arranged between two adjacent aluminum plates 19, and the number of rows and columns of aluminum plates 19 on each side is at least two rows , the length and width of each of the pressure plates 17 are larger than the length and width of the sides of the corresponding coal body sample 9, and the size of each side of the pressure plate 17 beyond the coal body sample 21 is larger than that of the aluminum plate 19 The thickness of the steel body is small, the aluminum plate 19 is rigid, and can carry out good stress transmission, and the rubbe...

Embodiment 3

[0030] Embodiment three: see figure 1 , figure 2 , a method for simulating using any of the aforementioned coal seam gas drainage borehole diameter variation simulation devices, comprising the following steps:

[0031] ① Coal body collection: collect coal bodies of typical geological units underground, transport them to the ground, seal them with wax, and pack them into boxes;

[0032] ② Coal body sample production: process and cut the collected coal body into a cubic coal body sample of 300mm×300mm, apply sealant evenly on the surface of the coal body sample, and the thickness of the colloid after curing is greater than 1mm;

[0033]③Fixation and stress pressurization of the coal sample: put the coal sample into the true triaxial pressure test device, and apply different stresses in various directions by adjusting the three vertical pressurization mechanisms;

[0034] ④ After the stress exerted on the coal sample is constant, an electric drill is used to open obs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com