System for testing damage to gradient composite under thermal/electric/magnetic/coupling action

A gradient material and testing system technology, applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve the problems that the testing of gradient material mechanics and electromagnetic performance indicators cannot be carried out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

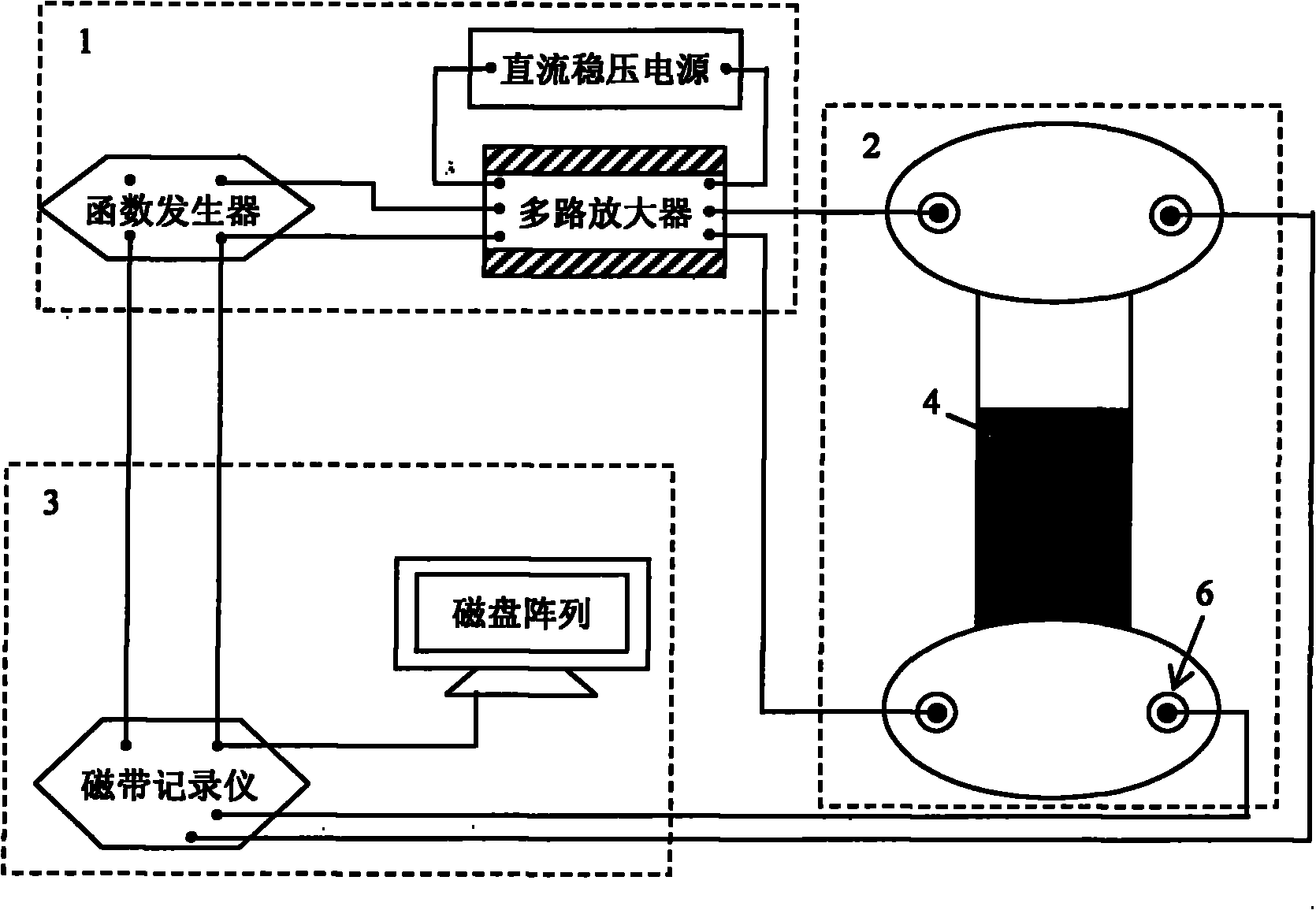

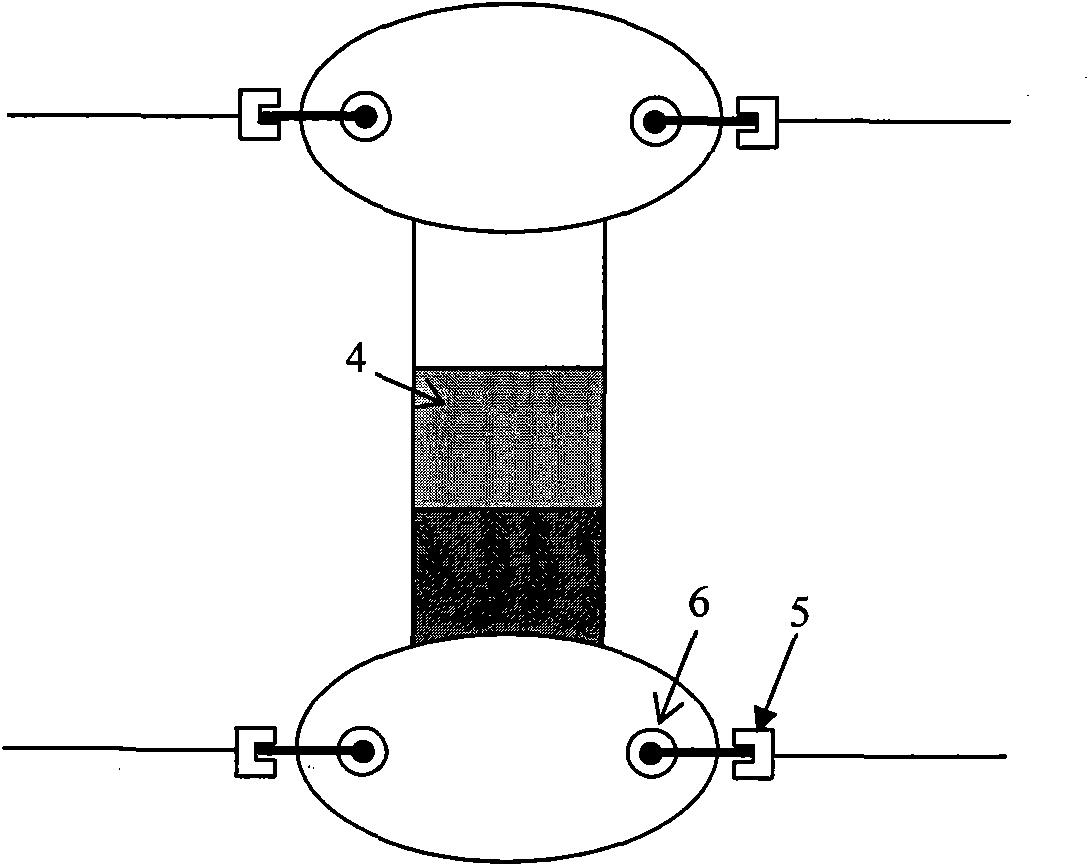

[0018] Embodiment: The electromagnetic principle diagram of the test system of the present invention is as follows figure 1 shown. A gradient layer with a thickness of 121 μm was prepared on a metal substrate by self-propagating combustion synthesis method, and a gradient material sample with a width of 20 μm and a length of 69 μm was cut. Such as figure 2 As shown, the sensor probe is fixed on the fixture, and the displacement of the fixture is controlled so that the probe of the sensor touches the gradient material, and then the current density applied to the gradient material is 82mA / cm 2 . actually built as figure 2 As shown, due to the alternating thermal stress generated by the direct current in the gradient material, the gradient material passes through 7.58×10 5 Seconds later, holes and microcracks and damages are generated, and further direct current is applied until failure occurs.

[0019] During the whole test process, the CCD probe of the scanning electron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com