Compact titanium diboride coating, preparation method of compact titanium diboride coating and application of compact titanium diboride coating

A titanium diboride and coating technology, applied in the field of dense titanium diboride coating and its preparation, can solve the problem of poor high temperature friction and wear performance of the coating, insufficiently dense grain structure of the coating, and adhesion between the coating and the substrate. It can reduce friction and wear, promote equiaxed crystal growth, and reduce metal adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

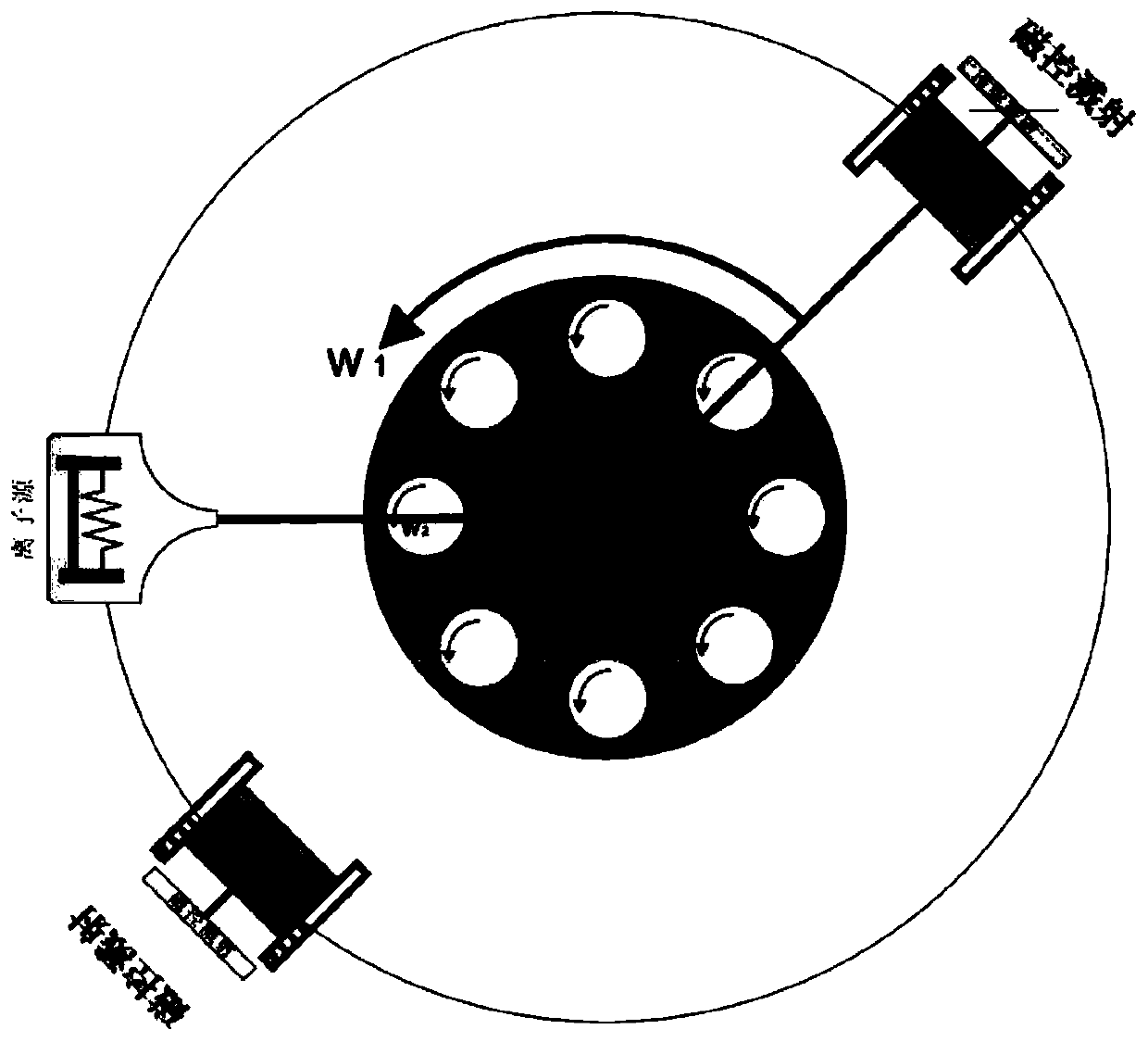

[0037] S1. Preparation of composite coating machine: In this implementation, an ion beam composite magnetron sputtering coating machine is selected, including a vacuum chamber, a magnetron sputtering source, an ion source and a workpiece support that can be rotated at the same time. Magnetron sputtering source loaded with 99.8% pure TiB 2 target;

[0038] S2. Substrate YT15 tungsten-cobalt-titanium alloy (WC-TiC-Co) pre-cleaning treatment: use alcohol to ultrasonically clean the sample (substrate) to be coated, then rinse with deionized water, and dry with dry compressed air;

[0039] S3. Use ion beam etching to clean the surface of the sample in the vacuum chamber: place the base YT15 tungsten-cobalt-titanium alloy on the workpiece support of the vacuum chamber, and evacuate the vacuum chamber to 5.0×10 –3 Below Pa, turn on the ion source, pass 150sccm of argon gas into the ion source, set the ion source current to 20A, set the workpiece support bias to -650V, and the workin...

Embodiment 2

[0045] S1. Preparation of composite coating machine: In this implementation, an ion beam composite magnetron sputtering coating machine is selected, including a vacuum chamber, a magnetron sputtering source, an ion source and a workpiece support that can be rotated at the same time. Magnetron sputtering source loaded with 99.8% pure TiB 2 target;

[0046] S2. Substrate YT15 tungsten-cobalt-titanium alloy (WC-TiC-Co) pre-cleaning treatment: use alcohol to ultrasonically clean the sample (substrate) to be coated, then rinse with deionized water, and dry with dry compressed air;

[0047] S3. Use ion beam etching to clean the surface of the sample in the vacuum chamber: place the base YT15 tungsten-cobalt-titanium alloy on the workpiece support of the vacuum chamber, and evacuate the vacuum chamber to 5.0×10 –3 Below Pa, turn on the ion source, pass 120sccm argon gas into the ion source, set the ion source current to 15A, set the workpiece support bias to -600V, and the working t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com