Solvent-free single-component moisture-hardening polyurethane adhesive for recreational vehicle body and preparation method of the adhesive

A polyurethane adhesive and hyperbranched polyurethane technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve problems such as adverse human health, air and ozone layer pollution, and achieve fast curing speed and good stability , good heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

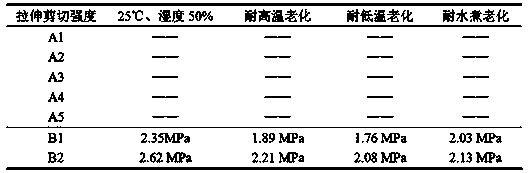

Examples

Embodiment 1

[0040] Mix 16g of phthalic acid and 57g of polyoxypropylene diol (hydroxyl value 279.5mgKOH / g) in a reactor, stir and heat under nitrogen atmosphere until completely melted, add catalyst tetrabutyl titanate, heat up to 170°C for 4 hours , continue to heat up to 230 ° C for 3 h. The acid value of the detection system is 8.23mgKOH / g, the pressure is reduced to below 0.02MPa, the reaction is maintained at 230°C, and the reaction is stopped when the acid value of the system is 0.42mgKOH / g. The hydroxyl value of the reaction product was detected to be 56.83 mgKOH / g, and the temperature was lowered to discharge to obtain polyether ester diol containing benzene rings.

[0041] Weigh 55 g of the above-prepared polyether ester diol containing benzene rings into the reactor, raise the temperature to 110° C., and vacuum dehydrate for 2 hours. Cool to 50°C, add 20.68g of carbodiimide-modified 4,4'-diphenylmethane diisocyanate, heat up to 65°C for 1 hour, add 0.62g of 1,4-butanediol, heat...

Embodiment 2

[0048] Mix 15g of phthalic acid and 48.2g of polyoxypropylene diol (hydroxyl value 282.7mgKOH / g) in a reactor, stir and heat under nitrogen atmosphere until completely melted, add catalyst tetrabutyl titanate, and heat up to 180°C for reaction 3h, continue to heat up to 230°C for 3h. The acid value of the detection system is 9.45mgKOH / g, the pressure is reduced to below 0.02MPa, and the reaction is maintained at 230°C until the acid value of the system is 0.38mgKOH / g to stop the reaction. The hydroxyl value of the reaction product was detected to be 56.48 mgKOH / g, and the temperature was lowered to discharge to obtain polyether ester diol containing benzene ring.

[0049] Weigh 55 g of the above-prepared polyether ester diol containing benzene rings into the reactor, raise the temperature to 110° C., and vacuum dehydrate for 2 hours. Cool to 50°C, add 24.09g of carbodiimide-modified 4,4'-diphenylmethane diisocyanate, heat up to 65°C for 1 hour, add 0.53g of 1,2-propanediol, h...

Embodiment 3

[0056] Mix 15g of phthalic acid and 54.2g of polytetrahydrofuran diol (hydroxyl value 281.3mgKOH / g) in a reactor, stir and heat under nitrogen atmosphere until completely melted, add the catalyst tetrabutyl titanate, and raise the temperature to 170°C for 4 hours , continue to heat up to 230 ° C for 3 h. The acid value of the detection system is 8.23mgKOH / g, the pressure is reduced to below 0.02MPa, and the reaction is maintained at 230°C until the acid value of the system is 0.47mgKOH / g to stop the reaction. The hydroxyl value of the reaction product was detected to be 57.21 mgKOH / g, and the temperature was lowered to discharge to obtain polyether ester diol containing benzene ring.

[0057] Weigh 65 g of the above-prepared polyether ester diol containing benzene rings into the reactor, raise the temperature to 110° C., and vacuum dehydrate for 2 hours. Cool to 50°C, add 30.09g of carbodiimide-modified 4,4'-diphenylmethane diisocyanate, heat up to 65°C for 1 hour, add 0.88g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com