A kind of water-based thick coating type water-based acrylic hybrid epoxy floor paint and preparation method thereof

A technology of water-based acrylic and epoxy floor paint, which is applied in the coating and other directions. It can solve the problems that the appearance effect is not as good as that of the solvent ring pull floor, the film-forming effect of the floor paint is poor, and the water-based volatilization is accelerated to achieve excellent drying speed. Good chemical resistance and the effect of improving drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

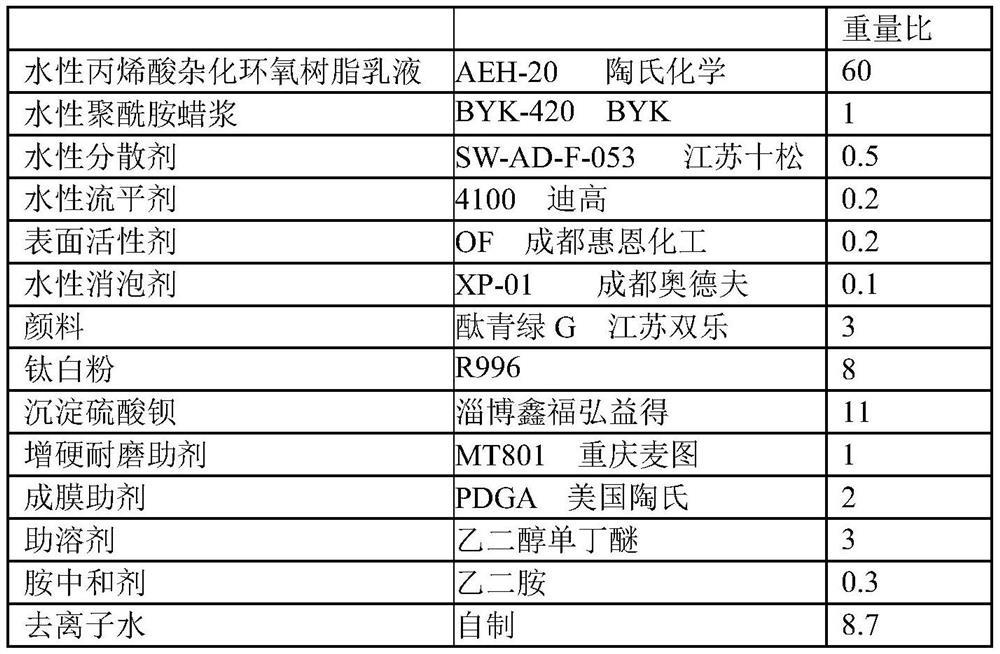

Embodiment 1

[0039]

[0040]

[0041]Adopt the weight proportion of above-mentioned raw material, preparation method is:

[0042] S1: Add water-based acrylic hybrid epoxy resin emulsion into the production tank;

[0043] S2: Dilute the water-based dispersant, water-based defoamer, water-based leveling agent, and surfactant with deionized water, then add it to the production tank, and stir at 300-400 rpm for 5-10 minutes;

[0044] S3: Add phthalocyanine green, titanium dioxide, precipitated barium sulfate, hardening and wear-resistant agent, and water-based polyamide wax slurry and stir at 800-1000 rpm for 15-20 minutes;

[0045] S4: use a sand mill to grind the fineness to 30 microns.

[0046] S5: Add film-forming aids, co-solvents, and water-based graphene slurry, and after stirring evenly, use a paint neutralizer to adjust the pH value to between 8 and 8.5.

Embodiment 2

[0048] Adopt the raw material of proportioning as shown in the table below:

[0049] weight ratio Waterborne Acrylic Hybrid Epoxy Resin Emulsion AEH-20 Dow Chemical 69 Water-based polyamide wax paste BYK-420 BYK 0.8 water-based dispersant SW-AD-F-053 Jiangsu ten pine 0.4 Water-based leveling agent 4100 Tego 0.3 Surfactant OF Chengdu Huien Chemical 0.3 Water-based defoamer XP-01 Chengdu Aodefu 0.2 pigment Phthalocyanine G Jiangsu Shuangle 4 Titanium dioxide R996 6 Precipitated Barium Sulfate Zibo Xinfu Hongyide 6 Hardening and wear-resistant additives MT801 Chongqing Maitu 1 Coalescent PDGA American Dow 2.5 Co-solvent Ethylene glycol monobutyl ether 4 Amine neutralizer Ethylenediamine 0.6 Deionized water self made 3.9 Graphene slurry 10% B111 Jiangsu Qualcomm Technology 1 total 100 Water-based modified cycloaliphatic amine epoxy curing ag...

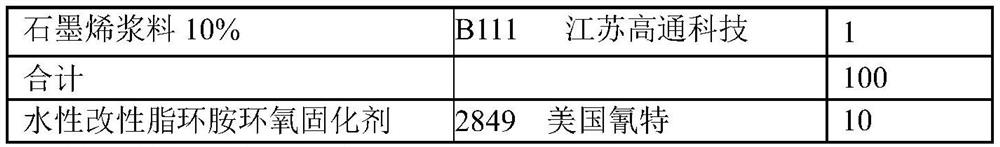

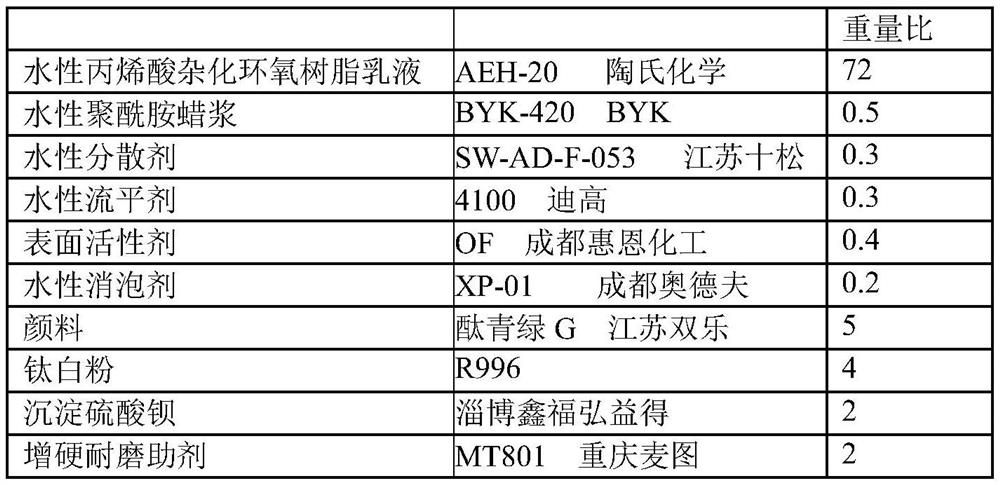

Embodiment 3

[0057] Adopt the raw material of proportioning as shown in the table below:

[0058] weight ratio Waterborne Acrylic Hybrid Epoxy Resin Emulsion AEH-20 Dow Chemical 72 Water-based polyamide wax paste BYK-420 BYK 0.5 water-based dispersant SW-AD-F-053 Jiangsu ten pine 0.3 Water-based leveling agent 4100 Tego 0.3 Surfactant OF Chengdu Huien Chemical 0.4 Water-based defoamer XP-01 Chengdu Aodefu 0.2 pigment Phthalocyanine G Jiangsu Shuangle 5 Titanium dioxide R996 2 Precipitated Barium Sulfate Zibo Xinfu Hongyide 5 Hardening and wear-resistant additives MT801 Chongqing Maitu 2 Coalescent PDGA American Dow 3 Co-solvent Ethylene glycol monobutyl ether 5 Amine neutralizer Ethylenediamine 0.4 Deionized water self made 2.9 Graphene slurry 10% B111 Jiangsu Qualcomm Technology 1 total 100 Water-based modified cycloaliphatic amine epoxy curing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com