Polytetrafluoroethylene-reinforced adhesion ceramic coating and preparation method thereof

A polytetrafluoroethylene and ceramic coating technology, used in coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of high operator requirements, difficult operation and high cost, and achieve wear resistance The effect of long life, low curing temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

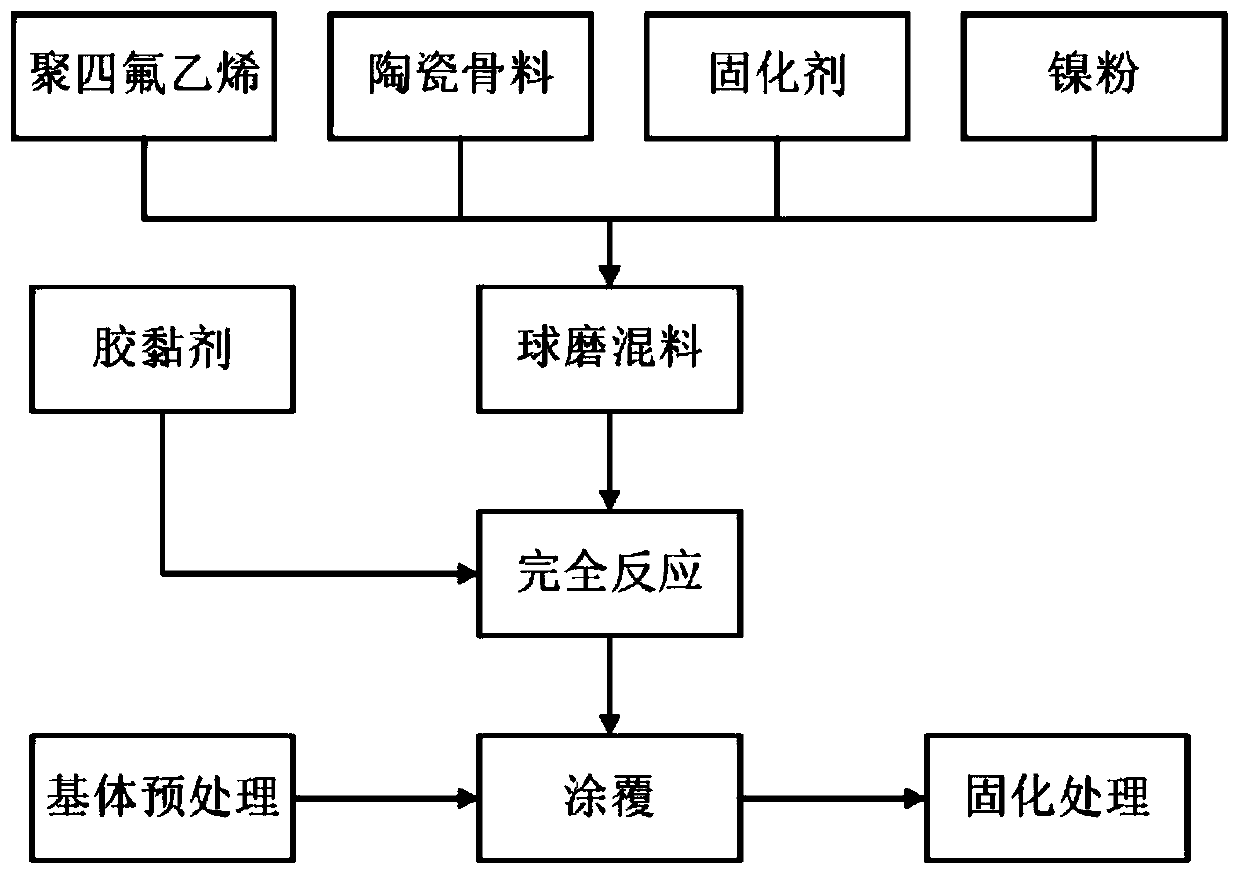

Method used

Image

Examples

Embodiment 1

[0029] (1) Substrate pretreatment: Grind the 45 steel substrate with sandpaper to remove surface rust marks, ultrasonically clean it in absolute ethanol for 15 minutes to remove surface stains, wash with deionized water, dry, and finally roughen the surface.

[0030] (2) Slurry preparation: Take by weighing 58.2wt% aggregate micro-alumina, 1wt% curing agent nano-zinc oxide, 0.6wt% nickel powder, 0.2wt% polytetrafluoroethylene according to the preparation steps, then pour Put it into a ceramic tank and perform ball milling in a planetary ball mill for 3 hours; measure 40wt% of the adhesive aluminum dihydrogen phosphate, and gradually add it dropwise to the mixture after ball milling, fully stir to form a sol, and let it stand for 1 to 2 days. ;Finally, spread the uniformly mixed slurry evenly on the pretreated 45 steel surface.

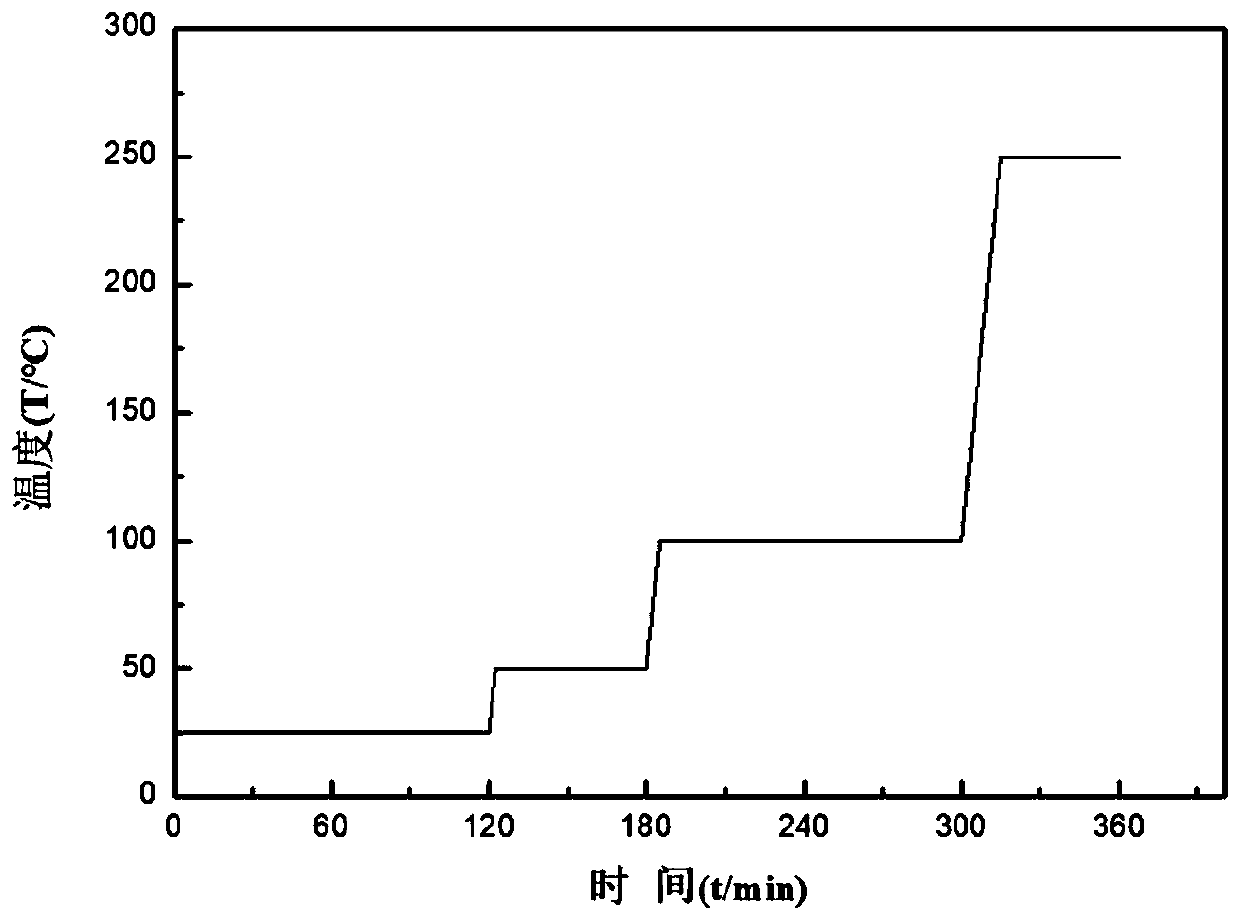

[0031] (3) Curing treatment: firstly cure at room temperature for 2 hours; then put it in a drying oven to raise the temperature to 50°C at a constant...

Embodiment 2

[0033] (1) Substrate pretreatment: Grind the 45 steel substrate with sandpaper to remove surface rust marks, ultrasonically clean it in absolute ethanol for 15 minutes to remove surface stains, wash with deionized water, dry, and finally roughen the surface.

[0034] (2) Slurry preparation: according to the preparation steps, weigh 58.0wt% aggregate micron alumina, 1wt% curing agent nano-zinc oxide, 0.6wt% nickel powder, 0.4wt% polytetrafluoroethylene, then pour Put it into a ceramic tank and perform ball milling in a planetary ball mill for 3 hours; measure 40wt% of the adhesive aluminum dihydrogen phosphate, and gradually add it dropwise to the mixture after ball milling, fully stir to form a sol, and let it stand for 1 to 2 days. ;Finally, spread the uniformly mixed slurry evenly on the pretreated 45 steel surface.

[0035] (3) Curing treatment: firstly cure at room temperature for 2 hours; then put it in a drying oven to raise the temperature to 50°C at a constant speed, a...

Embodiment 3

[0037] (1) Substrate pretreatment: Grind the 45 steel substrate with sandpaper to remove surface rust marks, ultrasonically clean it in absolute ethanol for 15 minutes to remove surface stains, wash with deionized water, dry, and finally roughen the surface.

[0038] (2) Slurry preparation: Take by weighing 57.8wt% aggregate micron alumina, 1wt% curing agent nano-zinc oxide, 0.6wt% nickel powder, 0.6wt% polytetrafluoroethylene according to the preparation steps, then pour Put it into a ceramic tank and perform ball milling in a planetary ball mill for 3 hours; measure 40wt% of the adhesive aluminum dihydrogen phosphate, and gradually add it dropwise to the mixture after ball milling, fully stir to form a sol, and let it stand for 1 to 2 days. ;Finally, spread the uniformly mixed slurry evenly on the pretreated 45 steel surface.

[0039] (3) Curing treatment: firstly cured at room temperature for 2 hours; then placed in a drying oven to raise the temperature to 50°C at a consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com