Three-dimensional current collector for metal lithium negative electrode of primary/secondary battery, metal lithium negative electrode and primary/secondary battery

A secondary battery and current collector technology, which is applied in the field of metal lithium negative electrodes and primary/secondary batteries, can solve the problems of damage to the specific capacity performance of composite electrodes, side reactions, poor conductivity and wettability, etc., and achieve good rapid charge and discharge capabilities, High-capacity charge/discharge and high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing the metal lithium negative electrode of the primary / secondary battery, which includes the following steps:

[0052] After oxidizing the above three-dimensional current collector in a strong oxidant, it is immersed in molten lithium metal to obtain a lithium metal negative electrode.

[0053] In the present invention, the strong oxidant is selected from a mixture of dilute sulfuric acid and potassium permanganate, a mixture of concentrated sulfuric acid and concentrated nitric acid, a mixture of concentrated sulfuric acid and potassium permanganate, a mixture of concentrated sulfuric acid and potassium dichromate, or Two or more of the above mixtures.

[0054] The concentration of the dilute sulfuric acid is 1-3M, the concentrated sulfuric acid is concentrated sulfuric acid with a mass percentage of ≥70%, and the concentrated nitric acid is nitric acid with a mass percentage of 90%-97.5%;

[0055] The strong oxidant is a...

Embodiment 1

[0075] 1. Preparation and testing of lithium@carbon tube paper metal anode by electrodeposition method

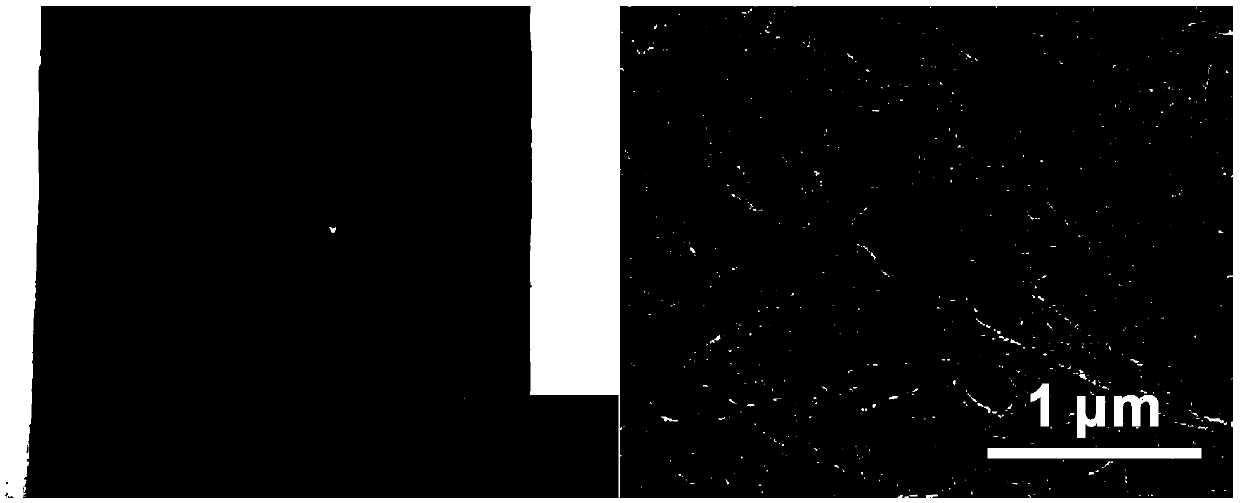

[0076] Punch the finished carbon tube paper with a punching tool with a diameter of 10mm (thickness 5-6μm, purchased from Suzhou Jidi Nano Co., Ltd.), see figure 1 , figure 1 For the optical photograph (left) and scanning electron microscope photograph (right) of the carbon tube paper in Example 1, a disc with a diameter of 10 mm was obtained. The disc is immersed in a mixed solution of ethanol and concentrated hydrochloric acid with a volume ratio of 10:1 and immersed at room temperature for 6 hours to remove surface oil and catalysts and other impurities. The soaked disc is washed twice in a mixture solution of 2:1 volume ratio of deionized water and ethanol.

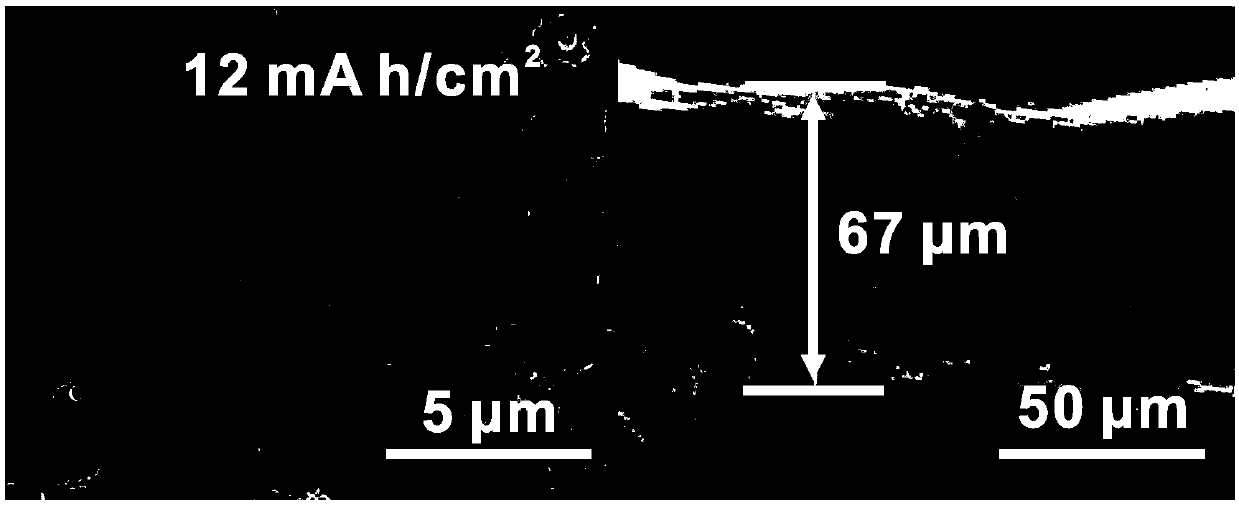

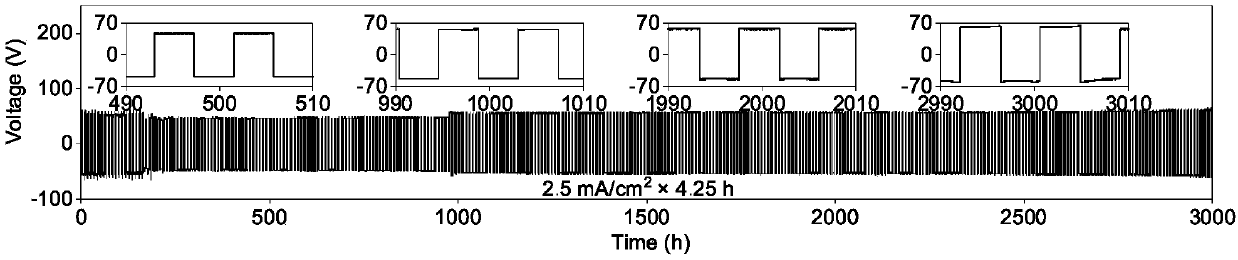

[0077] The cleaned carbon tube paper disc is used as the positive electrode, and the lithium plate is used as the negative electrode to assemble a two-electrode button battery. The electrolyte is 100uL 1,3-dioxolane / 1,...

Embodiment 2

[0083] Cut 4cm 2 Carbon tube paper (thickness 5.5±0.5μm, purchased from Suzhou Gedi Nano Co., Ltd.) is immersed in 4M concentrated sulfuric acid, then 1g potassium permanganate is added, stirred and heated in a water bath at 80°C for 6h, and wait for reaction The reaction is complete when the sidewall of the container appears brownish yellow. Take out the modified carbon tube paper and rinse it with deionized water for 15 seconds, and then soak it in a solution of ethanol and water with a volume ratio of 1:1 for 2 hours to complete the cleaning. Then, it was dried at 60° C. for 6 hours in an air atmosphere oven.

[0084] The dried modified carbon tube paper is still stamped as Put the wafer into a glove box in an argon atmosphere, and heat the lithium wafer to 260°C. The lithium wafer melts into a bright silver liquid. One end of the carbon tube paper is immersed in molten lithium, and the molten lithium reacts with the functional groups on the surface of the modified carbon tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com