Digital X-ray image detector and preparation method thereof

An image detector and X-ray technology, applied in the field of photodetectors, can solve problems such as image contrast reduction and image quality impact, and achieve the effects of improving image quality, eliminating crosstalk and improving transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

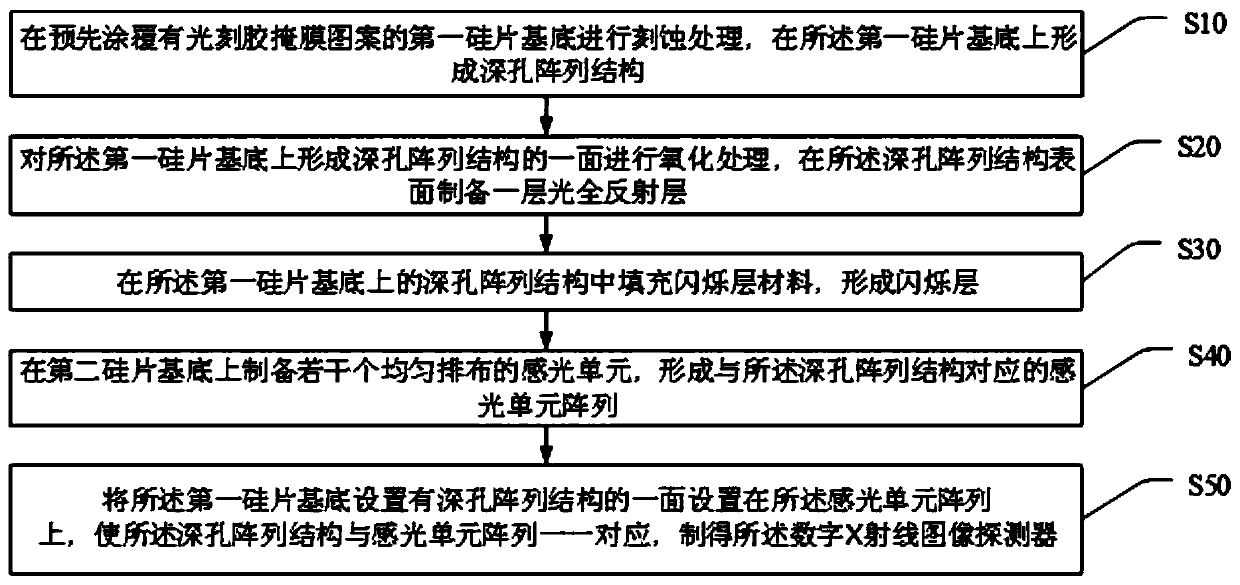

[0038] Further, the present invention also provides a method for preparing a digital X-ray image detector, wherein, as image 3 shown, including steps:

[0039] S10, performing an etching process on the first silicon substrate coated with a photoresist mask pattern in advance, forming a deep hole array structure on the first silicon substrate;

[0040] S20, processing the side on which the deep hole array structure is formed on the first silicon wafer substrate, preparing a layer of light total reflection layer on the surface of the deep hole array structure;

[0041] S30, filling the scintillation layer material in the deep hole array structure on the first silicon wafer substrate to form a scintillation layer;

[0042] S40, preparing several uniformly arranged photosensitive units on the second silicon wafer substrate to form a photosensitive unit array corresponding to the deep hole array structure;

[0043] S50. Place the side of the first silicon wafer substrate provide...

Embodiment 1

[0050] 1) Clean the double-sided polished N-type single crystal silicon wafer with acetone, absolute ethanol, and pure water to remove the stains on the surface; drop a drop of pure water on the silicon wafer, tilt the silicon wafer, and watch whether the pure water drops , if pure water drops, use a plasma cleaning machine to clean the silicon wafer again to increase the hydrophilicity of the silicon wafer;

[0051] 2) Perform coating, photolithography, and development on the cleaned silicon wafer to obtain a mask pattern;

[0052] 3) Aluminum grid structure is distilled on the back of the silicon wafer as an ohmic contact to ensure the uniformity of the electric field on the back of the silicon wafer, and the silicon wafer is immersed in an alkaline solution to form an inverted pyramid structure;

[0053] 4), silicon wafer is put into hydrofluoric acid solution, under the action of applied electric field, carry out the light-assisted electrochemical etching process in wet et...

Embodiment 2

[0059] 1), cleaning the P-type silicon wafer, uniform glue, photolithography and development, to obtain the mask pattern;

[0060] 2), etch the silicon wafer with the mask pattern obtained by dry etching, such as reactive ion etching (RIE), deep reactive ion etching (DRIE), etc., to form a deep hole array structure, and etch to obtain cleaning of the structure;

[0061] 3), process the cleaned silicon wafer with an atomic layer deposition device (ALD), and form an oxide film within 10nm on the inner wall of the deep hole structure (such as SiO 2 ,Al 2 o 3 etc.) or precious metal (e.g. nickel, rhodium, palladium, etc.) thin films;

[0062] 4), filling the deep hole array structure with a perovskite material to form a scintillation layer;

[0063] 5), remove the photoresist and make a one-to-one correspondence between the scintillation layer and the detection unit;

[0064] 6), preparing a layer of protective layer on the upper surface of the silicon chip with the deep hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Feature size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com