Compound long-acting injection containing enrofloxacin and flunixin and preparation method of compound long-acting injection

A technology of enrofloxacin and flunixin, which is applied in the field of compound long-acting injection and its preparation, can solve the problems of not exceeding 40°C, the injection is not subjected to terminal sterilization, and animal stress, etc., and can promote the prognosis and prognosis, enhancing animal compliance, improving outcomes and prognosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] Enrofloxacin or its salts are ultrafinely pulverized, and 90% of the particles have a particle size of ≤15 μm, and particles above 50 μm cannot be detected.

[0036] Flunixin and flunixin meglumine in dispersed form are ultrafinely pulverized, and 90% of the particles have a particle size of ≤5 μm, and no particles larger than 25 μm can be detected.

[0037] The ultrafine pulverization process of enrofloxacin or its salt, flunixin and flunixin meglumine: a fluidized bed supersonic airflow ultrafine pulverization classification system is adopted, and the amount of material entering is controlled at 60-80g. The materials collide with each other at the speed of Mach 2.5 in the crushing chamber, and are crushed quickly. The crushed particles rise to the classification chamber with the airflow, and the qualified particles enter the cyclone separator with the airflow, and finally obtain the desired product, and the tail gas enters the dust collector to be discharged. Under t...

Embodiment 1

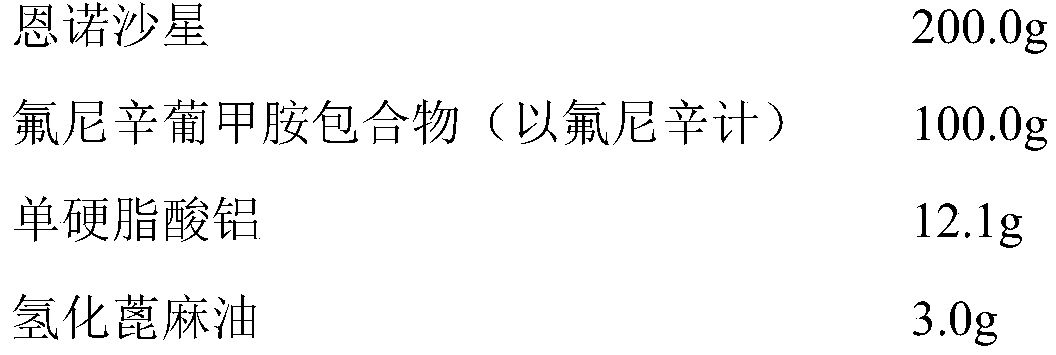

[0040] prescription

[0041]

[0042]

[0043] Preparation method: take an appropriate amount of ethyl oleate, heat it to 150-180°C, and continue for 1 hour; take 700mL of heated ethyl oleate and cool it down to 120-140°C, add aluminum monostearate and hydrogenated castor oil, and keep 1-2h to completely gel the aluminum monostearate and hydrogenated castor oil; then let cool to 40-60°C, add microcrystalline wax, Tween 80, Span 60, lecithin, enrofloxacin, enrolactate Flunixin, flunixin inclusion compound and flunixin, stir evenly, and dilute to 1000mL with ethyl oleate cooled to room temperature after heat treatment; test the particle size and content; subpackage after passing the test, and sterilize at 115°C for 30 minutes , the compound long-acting injection containing enrofloxacin injection and flunixin was obtained, and its in vitro performance evaluation was carried out, including the determination of properties, particle size, 3h sedimentation volume ratio, redispe...

Embodiment 2

[0050] prescription

[0051]

[0052]

[0053] Preparation method: Take an appropriate amount of medium-chain fatty acid, heat it to 150-180°C, and keep it for 1 hour; take 600mL of medium-chain fatty acid after heat treatment, cool it down to 120-140°C, add aluminum monostearate and hydrogenated castor oil, and keep it for 1 hour -2h, make it completely gelled; let cool to 40-60°C, add polyvinyl alcohol, Tween 80, Span 85, hydroxylated lecithin, enrofloxacin, flunixin meglumine inclusion compound, Stir well and evenly, use the medium-chain fatty acid cooled to room temperature after heat treatment to make up to 1000mL; test the particle size and content; subpackage after passing the test, and sterilize at 115°C for 30 minutes to obtain the compound containing enrofloxacin and flunixin For long-acting injections, the in vitro performance evaluation was carried out, including the determination of properties, particle size, 3h sedimentation volume ratio, redispersibility, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com