Thermoplastic magnetic composite material and preparation method thereof

A magnetic composite material and thermoplastic resin technology, applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of single molding size, difficulty in batch production, complex process, etc., achieve low cost, improve electromagnetic Good performance and anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

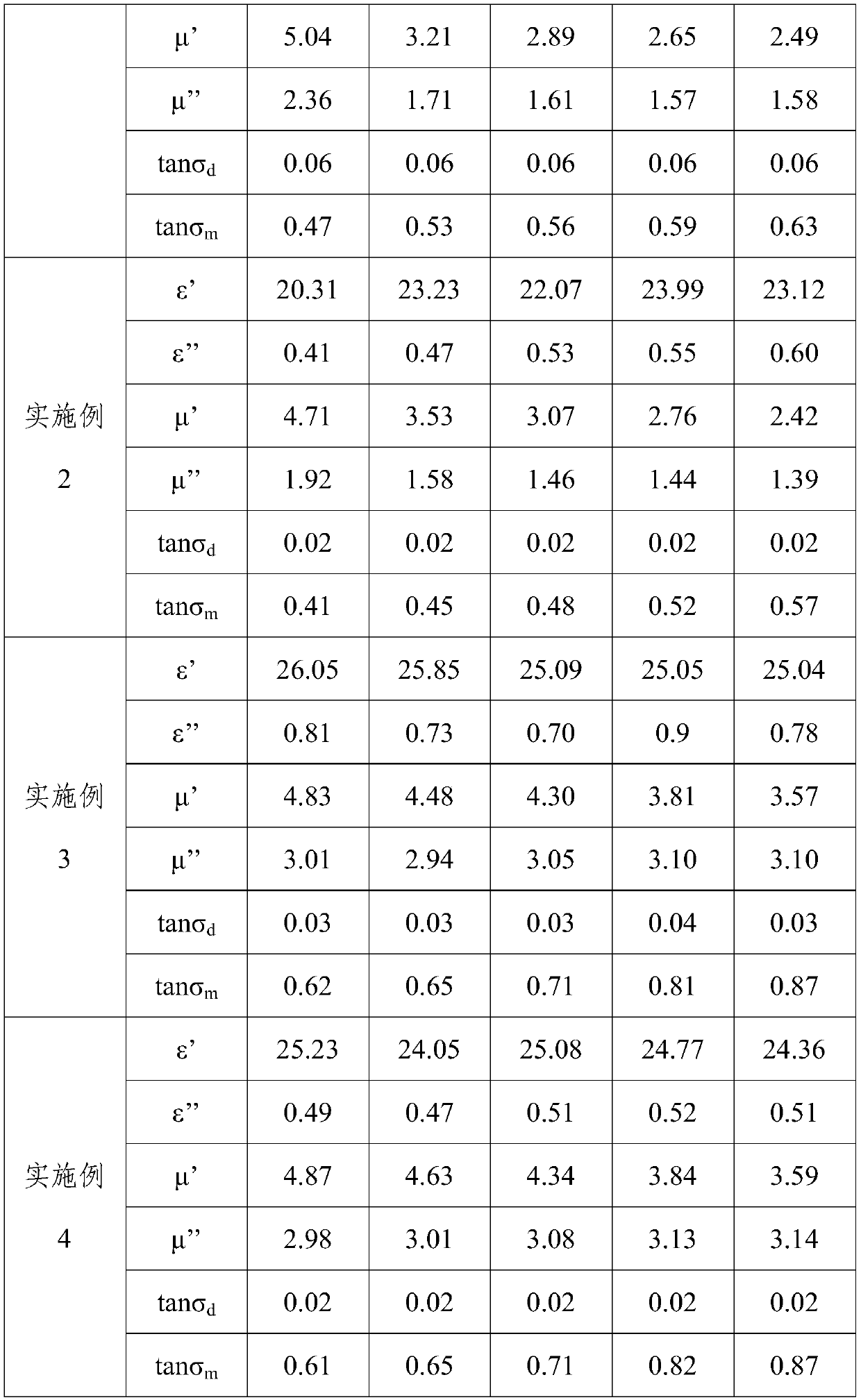

[0034] In the preparation method provided by the invention, carbonyl iron powder is coated with silicon dioxide. Silicon dioxide is a chemically inert material with good oxidation resistance and low cost. Coating a silicon dioxide film on the surface of carbonyl iron powder can increase carbonyl Antioxidant properties of iron powder. In addition, the dielectric constant and dielectric loss of the electromagnetic composite material prepared by coating silica carbonyl iron powder are both reduced, which makes the impedance matching of the composite material better, thereby improving the electromagnetic performance.

[0035] In some preferred embodiments, the first surface modifier and the second surface modifier are silane coupling agents, and the silane coupling agent is 3-(2,3-glycidoxy) propyl Trimethoxysilane, also known as KH560 or KH-560. The mass of the first surface modifier is preferably 3-4wt% of the mass of the carbonyl iron powder, and can be any value within this r...

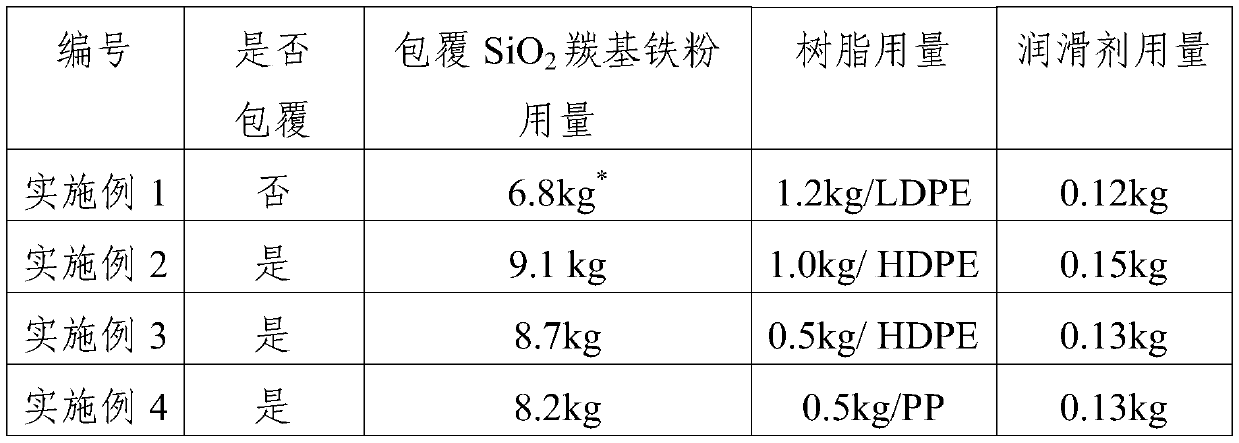

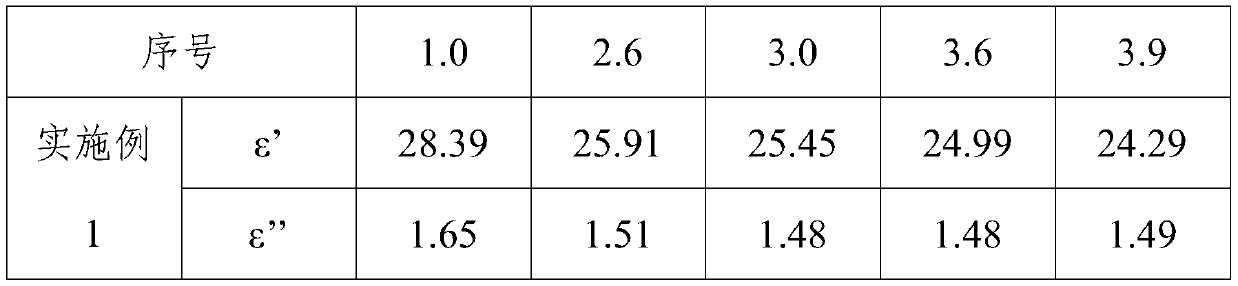

Embodiment 1

[0056] Carbonyl iron powder was directly compounded with thermoplastic resin to prepare carbonyl iron / resin composite material, and carbonyl iron was not coated with silica.

[0057] Concrete preparation method comprises the following steps:

[0058] S1. Weigh 6.8kg of carbonyl iron powder, 1.2kg of LDPE (Low Density Polyethylene), 0.21kg of KH560, and 0.12kg of triolein into the twin-screw extruder, and set the temperature of the heating zone to 105°C , 110°C, 120°C, 125°C, 130°C, 135°C, 140°C, 130°C, 130°C, 125°C, screw speed 300rpm, mixing and granulation three times to obtain carbonyl iron / resin masterbatch.

[0059] S2. Add the obtained carbonyl iron / resin masterbatch into the injection molding machine. The screw temperature zones are set to 130°C, 135°C, 140°C, 150°C, 155°C, and 145°C, the injection pressure is 113MPa, and the mold temperature is 75°C. Finally, the carbonyl iron / LDPE composite material is obtained by injection molding.

Embodiment 2

[0061] In this example, carbonyl iron powder is coated with silicon dioxide on the surface, and then compounded with thermoplastic resin to prepare carbonyl iron / resin composite material.

[0062] Concrete preparation method comprises the following steps:

[0063] S1. Weigh 10kg carbonyl iron powder, stir and mix with 300mL KH560, 1500mL ethanol, 400mL deionized water, then add ammonia water dropwise (commercially available 25% ammonia water, NH 3 The content is 25-28wt%, the density is 0.90-0.91g / cm 3 ) 60mL, TEOS (tetraethyl orthosilicate) 120mL into the mixed solution, reacted for 6h, and finally washed with alcohol and dried to obtain coated SiO 2 Carbonyl iron powder.

[0064] S2. Weigh 9.1kg coated SiO 2 Carbonyl iron powder, 1.0kg HDPE (High Density Polyethylene, high-density polyethylene), 0.27kg KH560, 0.15kg triolein were added to the twin-screw extruder, and the temperature of the heating zone was set to 160°C, 160°C, and 165°C respectively. °C, 175 °C, 185 °C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com