High-temperature-resistant antibacterial plastic and preparation method thereof

An antibacterial plastic and high temperature resistant technology, which is applied in the field of high temperature resistant antibacterial plastic and its preparation, can solve the problems that high temperature objects cannot be used in sealed storage, processing and molding conditions are harsh, and sealing cannot be applied, so as to improve elasticity, high elastic deformation performance, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The specific preparation process of silylated polyimide is as follows:

[0022] Step 1: Weigh 150g of tartaric acid and add it to 1L of acetone and stir to dissolve it. At the same time, add 138.3g of potassium hydroxide and 18.6g of nano-silicon dioxide powder to it, raise the temperature to 150-160°C for reflux reaction for 24h, and then carry out vacuum distillation to obtain silicon Potassium oxyalkyltetracarboxylate;

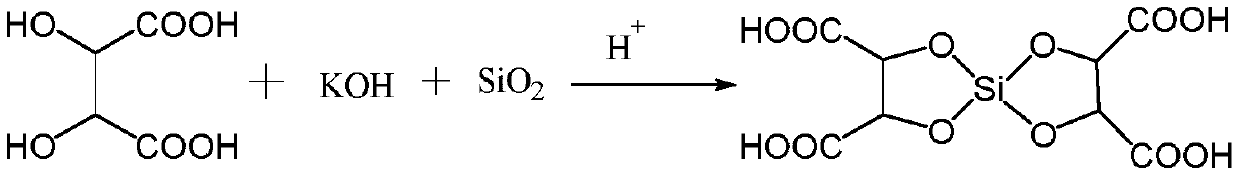

[0023] Step 2: Add 100 g of the potassium siloxane tetracarboxylate prepared in step 1 to 1.5 L of hydrochloric acid with a mass concentration of 1% and reflux at room temperature for 2-3 hours, then filter, wash and dry to obtain silanized tetracarboxylate acid, the reaction structure is as follows:

[0024]

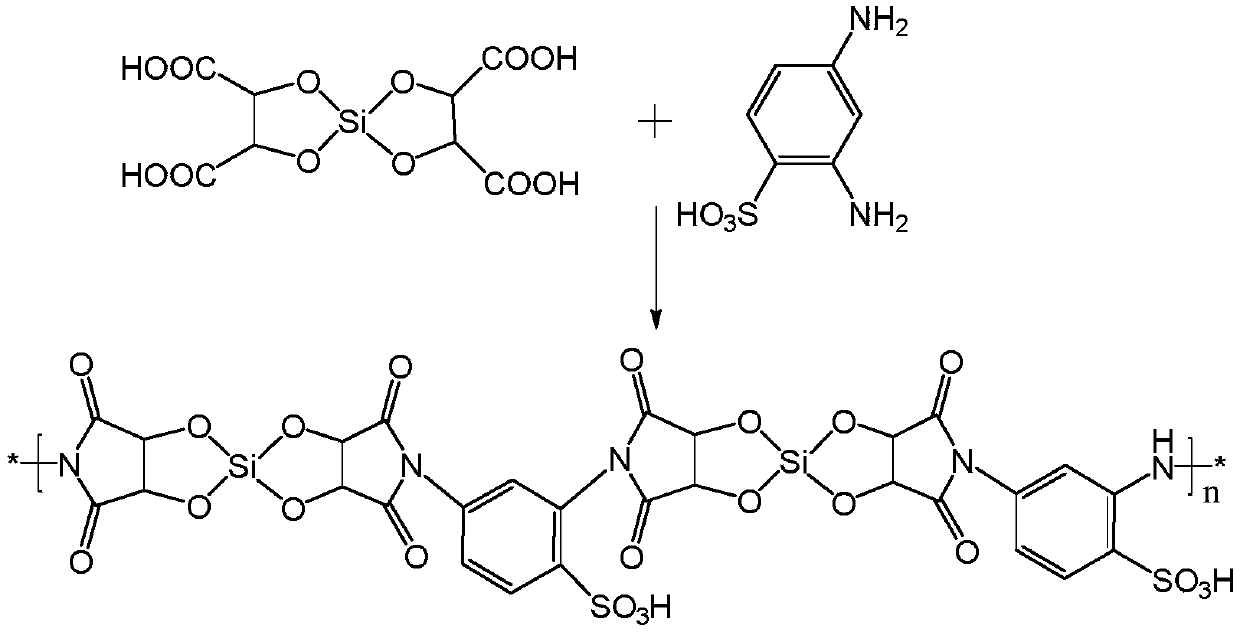

[0025] Step 3: Add 199.5g of 2,4-diaminobenzenesulfonic acid and 1.2L of anhydrous N-methylpyrrolidone into the reaction flask, then continuously feed nitrogen into the reaction flask for 20-30min, and add 320g of For the silanized tetrac...

Embodiment 2

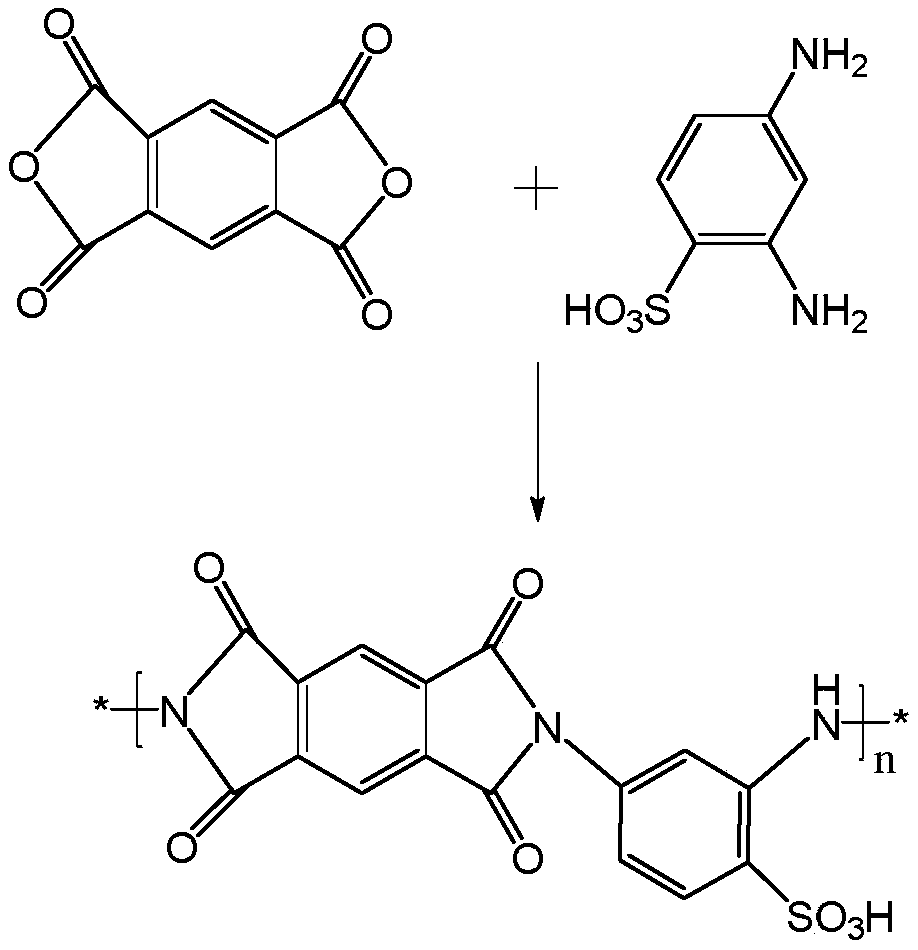

[0028] The specific preparation process of polyimide is as follows: add 199.5g of 2,4-diaminobenzenesulfonic acid and 1.2L of anhydrous N-methylpyrrolidone into the reaction flask, and then continuously feed nitrogen into the reaction flask for 20-30min, And add 218g of pyromellitic dianhydride to the reaction flask, heat up to 130-135°C for reflux reaction for 2-3h, then heat up to 180-185°C for reflux reaction for 5-6h, then centrifuge the product to obtain polyimide , the reaction structure is as follows:

[0029]

Embodiment 3

[0031] A preparation method of high temperature resistant antibacterial plastics, the specific preparation process is as follows:

[0032] In the first step, 700 g of the silanized polyimide prepared in Example 1 and 250 g of nitrile rubber are simultaneously added to the internal mixer and masticated at 120-130 ° C for 2-3 min;

[0033] In the second step, add 60g of plasticizer, 3g of sulfur and 10g of 2,8-di-tert-butyl-4-methylphenol to the internal mixer and keep the temperature constant for 5-8min;

[0034] The third step is to raise the temperature of the masticator to 200-210°C, then add 31g of sulfadiazine to it, and masticate for 10-12min to obtain plastic;

[0035]The fourth step is to add the plastic prepared in the third step into the open mill, adjust the roller distance to about 5mm to dissipate heat, and then carry out thin pass 2-3 times, turn over 1-2 times and then release the sheet, cool and park for 2-3h, Then put it into a flat vulcanizer for vulcanizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com