Method for determining manganese and titanium content in ferrophosphorus through microwave digestion ICP-AES method

A technology of ICP-AES and microwave digestion, which is applied in the field of analytical chemistry, can solve the problems of complex melting process, inability to measure, and long time consumption, and achieve the effect of avoiding environmental pollution, no impact on accuracy, and simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment is a kind of microwave digestion ICP-AES method for the determination of manganese and titanium content in ferrophosphorus, including microwave assisted digestion and dissolution, preparation of standard solution, drawing of standard curve, and determination of ferrophosphorus sample;

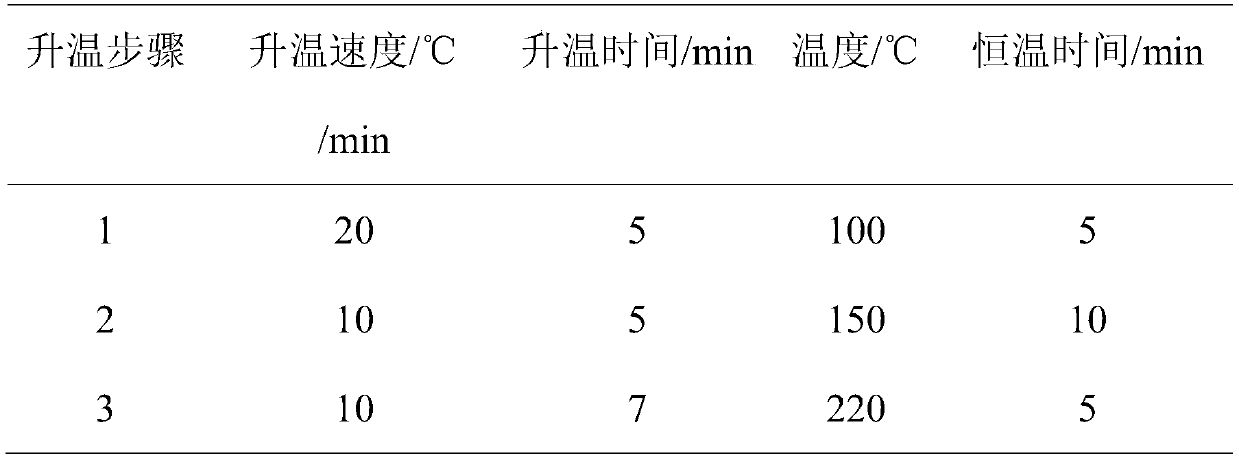

[0023] (1) Microwave-assisted digestion and dissolution of samples: Accurately weigh 0.2000g of ferrophosphorus standard sample (GBW(E)010420) into a microwave digestion tank, add 5mL of pure water, nitric acid with a concentration of 1.42g / mL and nitric acid with a concentration of 1.19g / mL Add 5 mL of hydrochloric acid each, then add 2 mL of hydrofluoric acid with a concentration of 1.15 g / mL, shake gently, and wait until there is no reaction, then tighten the lid of the digestion tank, and perform microwave digestion according to the procedures in Table 1; , add 2mL saturated boric acid solution, cool the test solution, transfer it to a volumetric flask and make ...

Embodiment 2

[0038] The present embodiment is a kind of microwave digestion ICP-AES method for the determination of manganese and titanium content in ferrophosphorus, including microwave assisted digestion and dissolution, preparation of standard solution, drawing of standard curve, and determination of ferrophosphorus sample;

[0039] (1) Microwave-assisted digestion and dissolution of samples: Accurately weigh 0.1000g of ferrophosphorus standard sample (ZBT384)

[0040] Yu Microwave

[0041] In the digestion tank, add 5mL of pure water, 5mL of 1.42g / mL nitric acid and 1.19g / mL hydrochloric acid each, then add 1mL of 1.15g / mL hydrofluoric acid, shake gently, and wait for After the reaction, tighten the lid of the digestion tank, and carry out microwave digestion according to the procedure in Table 5; after the digestion is completed, add 2 mL of saturated boric acid solution, cool the test solution, transfer it to a volumetric flask and make it to volume;

[0042] Table 5 Microwave diges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com