Blackboard panel production system

A production system and panel technology, which is applied in the direction of pretreatment surface, device for coating liquid on surface, spray device, etc., can solve the problems of uneven cooling, poor air-drying effect and spraying effect, low cooling efficiency, etc. Effects of reduced human health impacts, lower equipment and personnel health, and lower acid levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

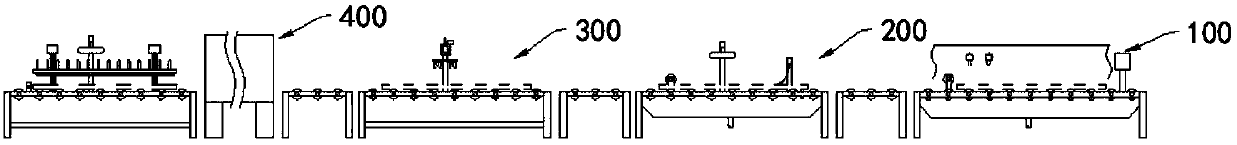

[0035] Embodiment: blackboard panel production system, constitutes as Figure 1 to Figure 10 As shown, it includes a cleaning device 100 , an air-drying device 200 , a spraying device 300 and a post-processing device 400 arranged in sequence, and the devices are sequentially connected by transport rollers.

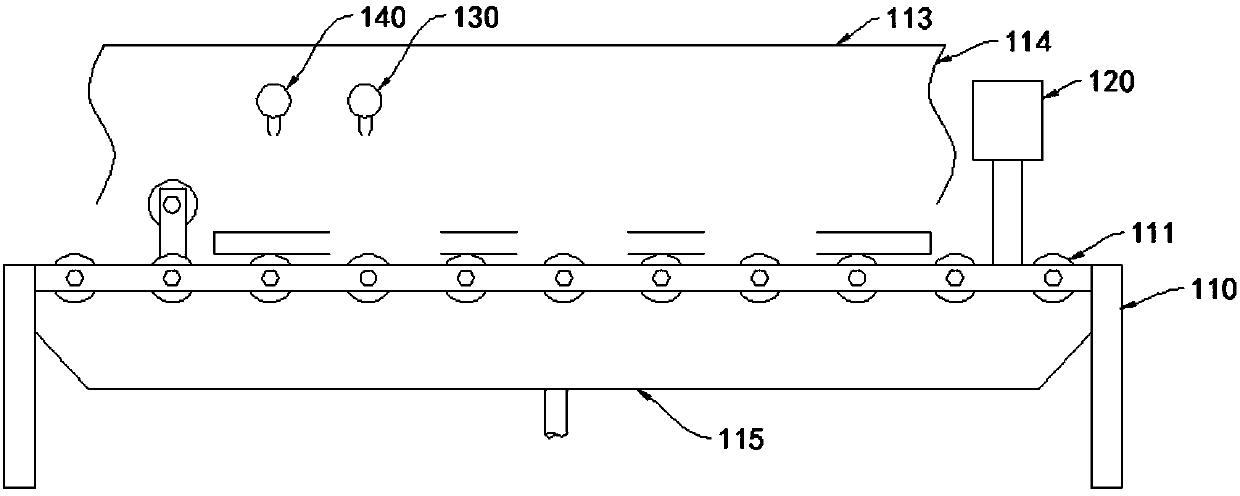

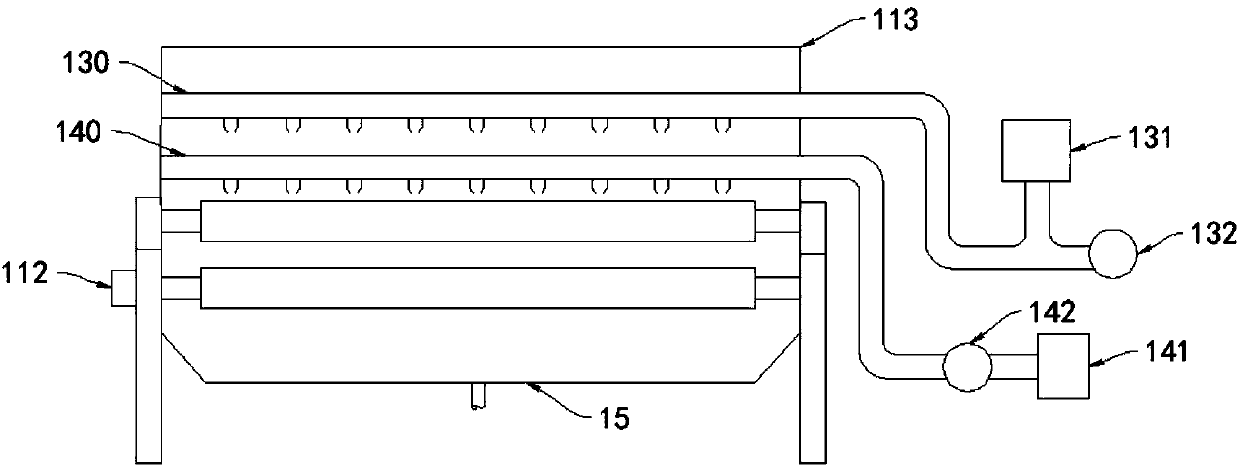

[0036] The cleaning device 100 includes a first frame 110, the first frame 110 is provided with a first roller group 111, and the side of the first frame 110 is provided with a first feed motor 112; Along the feeding direction, a degaussing device 120, a quicksand pipeline 130 and a spray pipeline 140 are successively provided with corresponding nozzles; the quicksand pipeline 130 is also connected with a storage device 131 and compressed air device 132, and quicksand pipeline 130 and compressed air device 132 are arranged on both sides of sand storage device 131 respectively; Described spray pipeline 140 is connected with cleaning agent storage device 141, spray pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com