Low-acid-value Yunnan pine seed oil, preparation method and application thereof

A technology of pine nut oil and low acid value, which is applied in the fields of fat oil/fat refining, fat oil/fat production, medical raw materials derived from gymnosperm submenus, etc. The method is cumbersome, the required process is complicated, etc., and the effect of saving energy consumption, cost and energy consumption, and simple extraction process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

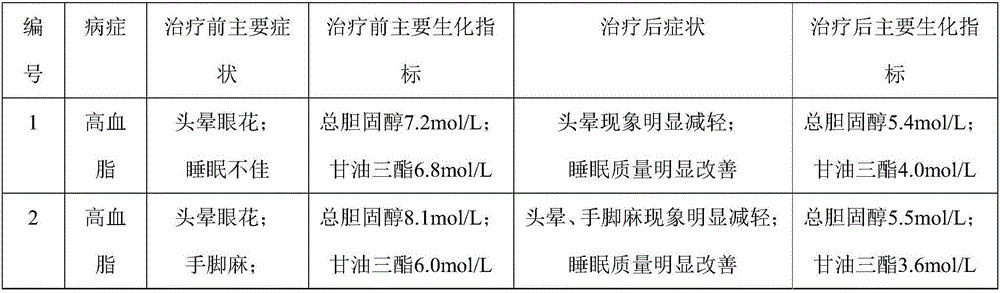

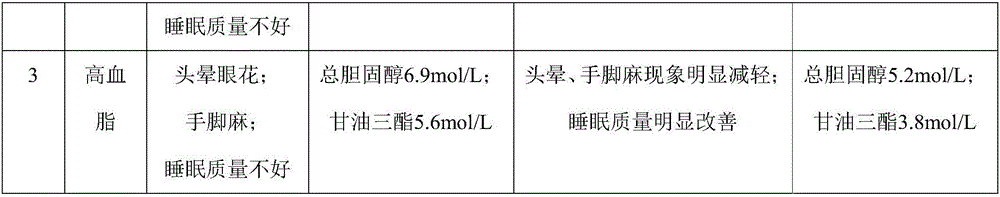

Examples

Embodiment 1

[0049] Collect 6 tons of pine nuts, after screening, winnowing, and flotation, remove impurities, earth, stones, fine sand, dust, empty shells, and tail fins, then dry them at 40°C, press them with a flaking machine, and press oil with a screw The machine repeatedly squeezes to obtain crude oil, and the oil extraction rate is above 70%. The crude oil was filtered with a plate and frame filter press to remove impurities, added a phosphoric acid solution with a mass fraction of 5% and a citric acid solution with a mass fraction of 10%, mixed evenly at 25°C and allowed to settle for 4 hours, separated the oil layer, and dried in vacuo to obtain Degummed oil; then add 7% sodium hydroxide solution, deacidify at 60°C, make the acid value reach 1.5mg KOH / g, add hot water at 50°C to wash, drain after 6 hours of precipitation; add 10% sodium hydroxide again Solution, deacidify at 60°C to make the acid value reach 1.0mg KOH / g, add hot water at 50°C to wash, drain after 6 hours of precip...

Embodiment 2

[0057] Collect 5 tons of pine nuts, remove impurities, soil stones, fine sand, dust, empty shells, and tail fins after screening, winnowing, and flotation, then dry them at 50°C, press them with a flaking machine, and press them with double pendulums. The oil machine is repeatedly squeezed to obtain crude oil, and the oil extraction rate is above 70%. The crude oil was filtered with a box-type filter press to remove impurities, added a phosphoric acid solution with a mass fraction of 5% and a citric acid solution with a mass fraction of 10%, mixed evenly at 60°C and allowed to settle for 4 hours, separated the oil layer, and dried in a vacuum to obtain Degummed oil; then add 7% sodium hydroxide solution, deacidify at 60°C, make the acid value reach 1.2mg KOH / g, add 50°C hot water to wash, drain after 6 hours of precipitation; add 10% sodium hydroxide again Solution, deacidify at 60°C to make the acid value reach 0.6mg KOH / g, add hot water at 50°C to wash, drain after 6 hours o...

Embodiment 3

[0064] Collect 5 tons of pine nuts, after screening, winnowing, and flotation, remove impurities, earth, rocks, fine sand, dust, empty shells, and tail fins, then dry them at 60°C, press them with a flaking machine, and press them with double pendulums. The oil machine is repeatedly squeezed to obtain crude oil, and the oil extraction rate is above 70%. The crude oil was filtered with a box-type filter press to remove impurities, added a phosphoric acid solution with a mass fraction of 5% and a citric acid solution with a mass fraction of 10%, mixed evenly at 60°C and allowed to settle for 4 hours, separated the oil layer, and dried in a vacuum to obtain Degummed oil; then add 7% sodium hydroxide solution, deacidify at 60°C, make the acid value reach 1.3mg KOH / g, add hot water at 50°C to wash, drain after 6 hours of precipitation; add 10% sodium hydroxide again Solution, deacidify at 60°C to make the acid value reach 0.7mg KOH / g, add hot water at 50°C to wash, drain after 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com