Preparation method of nickel-chromium chromium carbide wear-resistant coating

A wear-resistant coating and chromium carbide technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of inapplicability in the production of large batches or large parts, inconvenient operation of equipment, and cracks in the coating. , to achieve the effects of ease of automation, energy concentration, and reduction of internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of nickel-chromium carbide wear-resistant coating of the present invention comprises the following steps:

[0035] In the first step, the NiCr and Cr 3 C 2The powder is mixed evenly according to the ratio, and the powder particle size is 25-30 μm. After sintering, the nickel-chromium chromium carbide powder is obtained. The sintering temperature is 1400 degrees Celsius.

[0036] The second step is to prepare nickel-chromium chromium carbide (NiCr-Cr 3 C 2 ) remelted coating:

[0037] 1) Sand blasting pretreatment of the surface of the substrate;

[0038] 2) Plasma spraying the sandblasted substrate;

[0039] 3) Preheat the coating sample after plasma spraying before remelting, then use tungsten argon arc welding machine (YC-300WX welding machine) for TIG remelting treatment, and then perform heat preservation after remelting, Finally, a nickel-chromium carbide wear-resistant remelting coating is obtained; argon is used as a protective ...

Embodiment 1

[0047] This embodiment adopts nickel chromium carbide (NiCr-Cr 3 C 2 ) powder is proportioned according to the mass distribution ratio of 3:7. 30% NiCr and 70% Cr 3 C 2 The powders were mixed in a ball mill mixer for 24 hours, dispersed and bonded in a mixing tank after mixing, and then spray-dried. 30% NiCr-Cr after drying 3 C 2 The powder particles were sintered at 1400°C for 2 hours in an atmosphere protection furnace, taken out and crushed, and sieved with a 500-mesh standard sieve. Get 25-30μm nickel-chromium chromium carbide (30%NiCr-Cr 3 C 2 )powder.

[0048] Nickel-chromium carbide (NiCr-Cr 3 C 2 ) The main steps of coating preparation include: Spraying corundum sand on the substrate 45 steel so that the surface roughness (Ra) of the substrate is 3.2-6.4μm → feeding in the arcing ion gas → power supply to the spraying equipment → arcing of the plasma spray gun → arcing to the The spray powder is sent into the plasma stream to spray the surface of the workpie...

Embodiment 2

[0061] This embodiment also adopts nickel-chromium carbide (NiCr-Cr 3 C 2 ) powder with a particle size of 25-30 μm. Relative to embodiment 1, change powder NiCr and Cr 3 C 2 The composition ratio of NiCr is adjusted from 30% to 25%, while Cr 3 C 2 The proportion is adjusted from 70% to 75%.

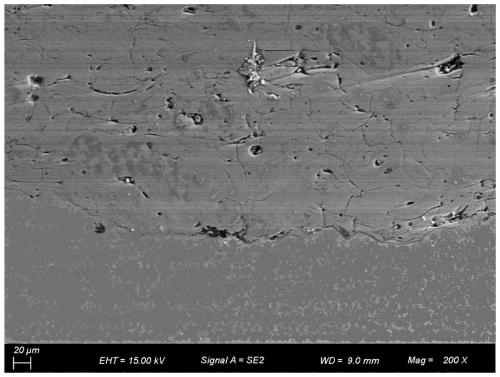

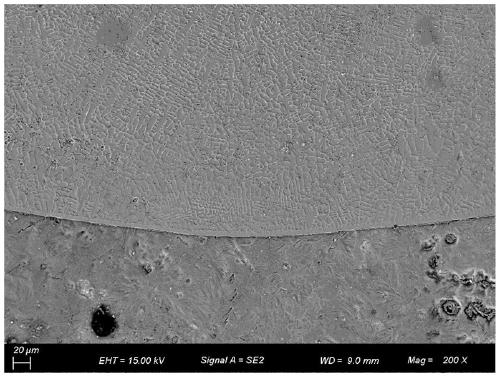

[0062] The other steps are the same as in Example 1, and the resulting coating has more internal cracks. The metallographic images of the coating section of embodiment 1 and embodiment 2 are as follows: Figure 10 As shown in (a) and (b), the increase in cracks in Example 2 is due to the high content of ceramics, which makes the coating easy to crack, but the overall is still metallurgical bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com