Glass processing protective film capable of being directly cut and preparation method thereof

A technology of processing and protective film, which is applied in the field of film materials, can solve the problems of cutting edge strength reduction, debris, fragments and micro-cracks, etc., and achieve the effect of ensuring cutting accuracy, fast hardening, and good crushing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

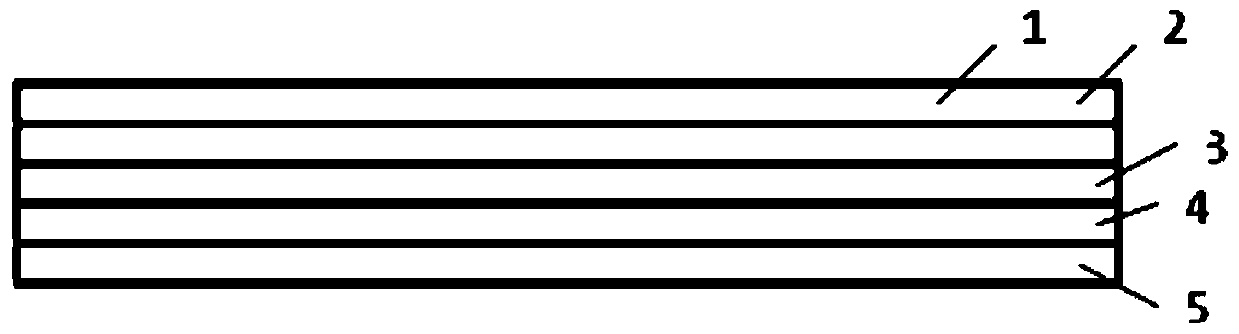

[0025] A method for preparing a directly cuttable glass processing protective film, comprising the following steps:

[0026] (1) A layer of acrylic pressure-sensitive adhesive is coated on the surface of 20um PET film 1 to form a glue layer 2 of 5um, with 110 parts of aliphatic urethane acrylate oligomer, 35 parts of cyclohexyl acrylate, 15 parts of more Ether amine, pour 350 parts of ethanol into the mixer, add 0.03 parts of photoinitiator, fully stir for 20 minutes to disperse, apply it on the glue layer 2 by scraping, and dry it to form a 20um The photohardening layer 3 is standby; the molecular weight of the polyetheramine is 230;

[0027] (2) Put 15 parts of polyvinyl alcohol, 1.5 parts of nano-alumina, 15 parts of natural latex, and 15 parts of methacrylate copolymer in a high-speed mixer, and after fully stirring for 7 hours, coat it on the photohardening surface. A 10um elastic adhesive layer 4 is formed on the layer 3, and the bottom paper layer 5 can be pasted; the ...

Embodiment 2

[0029] A method for preparing a directly cuttable glass processing protective film, comprising the following steps:

[0030] (1) A layer of acrylic pressure-sensitive adhesive is coated on the surface of 20um PET film 1 to form a glue layer 2 of 5um, with 100 parts of aliphatic urethane acrylate oligomer, 40 parts of cyclohexyl acrylate, more than 10 parts Ether amine, pour 400 parts of ethanol into the mixer, add 0.01 part of photoinitiator, fully stir for 20 minutes to disperse, apply it on the glue layer 2 by scraping, and dry it to form a 20um The photohardening layer 3 is standby; the molecular weight of the polyetheramine is 230;

[0031] (3) Put 20 parts of polyvinyl alcohol, 1 part of nano-alumina, 20 parts of natural latex, and 10 parts of methacrylate copolymer in a high-speed mixer, and after fully stirring for 8 hours, coat it on the photohardening surface. A 10um elastic adhesive layer 4 is formed on the layer, and the bottom paper layer 5 can be pasted; the poly...

Embodiment 3

[0033] A method for preparing a directly cuttable glass processing protective film, comprising the following steps:

[0034] (1) A layer of acrylic pressure-sensitive adhesive is coated on the surface of 20um PET film 1 to form a glue layer 2 of 5um, with 120 parts of aliphatic urethane acrylate oligomers, 30 parts of cyclohexyl acrylate, 20 parts of more For ether amine, pour 300 parts of ethanol into the mixer, add 0.05 parts of photoinitiator, fully stir for 20 minutes to disperse, apply it on the glue layer by scraping, and dry it to form a 20um The photohardening layer 3 is ready for use; the molecular weight of the polyetheramine is 230;

[0035] (3) Put 10 parts of polyvinyl alcohol, 2 parts of nano-alumina, 10 parts of natural latex, and 20 parts of methacrylate copolymer in a high-speed mixer, and after fully stirring for 6 hours, coat it on the photohardening surface. A 10um elastic adhesive layer 4 is formed on the layer 3, and the bottom paper layer 5 can be paste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com