Screw-type straightening method for tap bolt of slender rod

A slender rod and spiral technology, applied in the field of spiral straightening, can solve problems such as poor straightening effect, microcracks or fractures, and achieve good straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

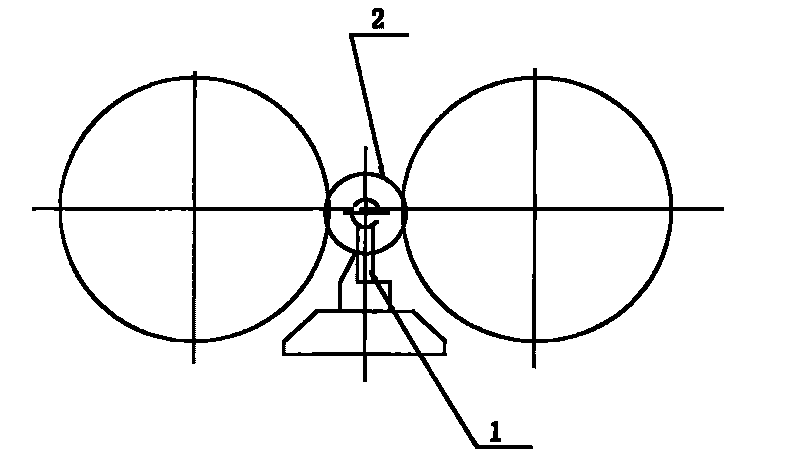

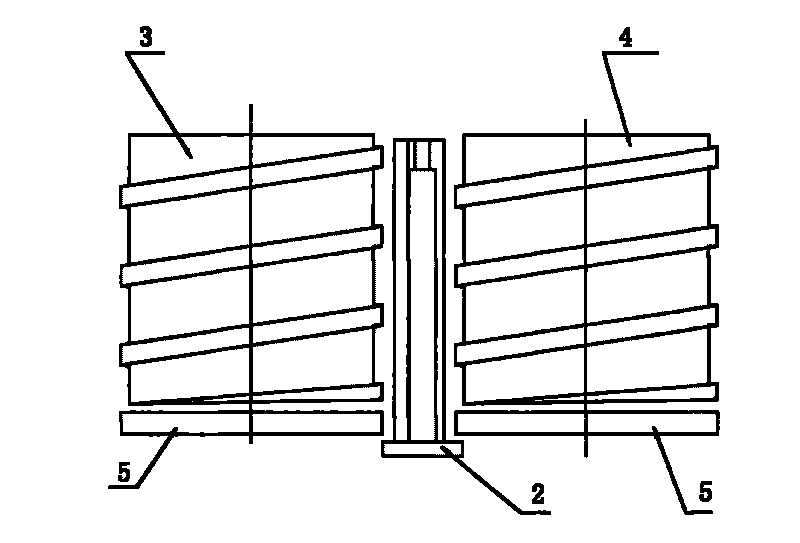

[0010] Combine below figure 1 , 2 As shown, the present invention is further described as follows: a spiral straightening method of a slender rod headed bolt, comprising a pair of straightening rollers 3,4 and auxiliary rollers 5, and the outer circle of the straightening rollers 3,4 is provided with a convex For the single-head helical surface, the width of the auxiliary roller 5 is the same as the thread pitch of the straightening rollers 3 and 4; a pair of straightening rollers 3 and 4 and the auxiliary roller 5 are respectively fixed on a pair of rotating shafts rotating in the same direction. After fixing, the stagger angle of the helical surfaces of the straightening roller 3 and the straightening roller 4 is 180 °, and the auxiliary roller 5 is corresponding to the root of the rod portion of the slender rod with the head bolt 2, and is set between the straightening rollers 3 and 4. There is a support block 1, and the height of the support block 1 should ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com