A kind of preparation method of high thermal conductivity composite filler and polymer-based composite material thereof

A technology of thermally conductive fillers and composite fillers, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of limited thermal conductivity of composite materials, obstacles to industrialized large-scale production, and low thermal conductivity of thermally conductive fillers, etc., to achieve broad thermal conductivity Application prospect, lower percolation threshold, and effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

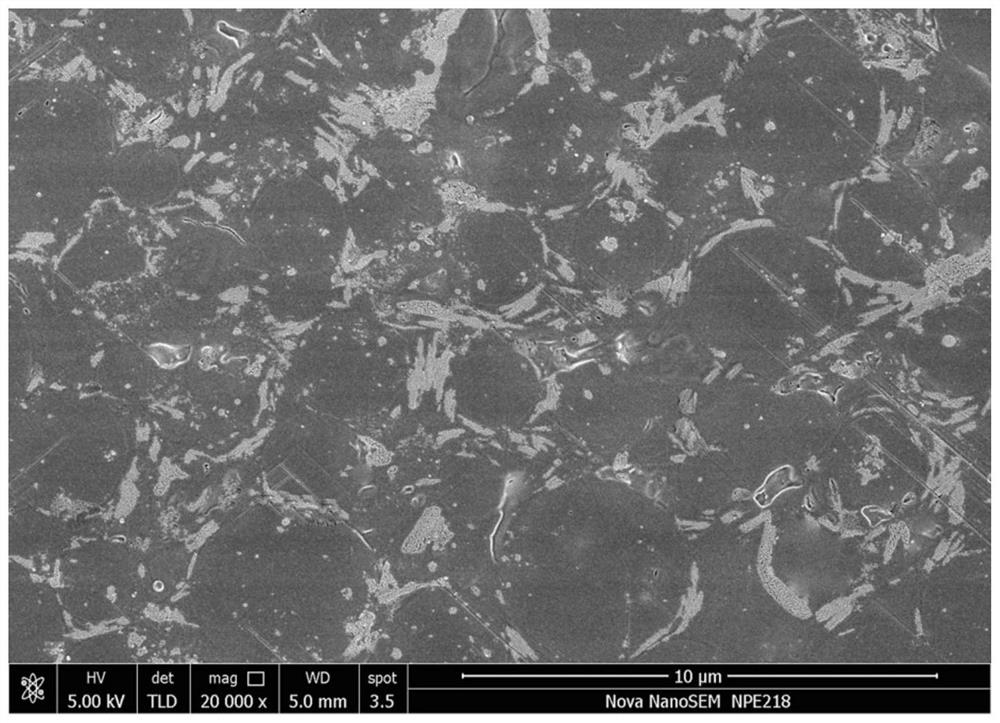

[0041] This embodiment relates to a preparation method of a high thermal conductivity composite filler and the epoxy composite material filled therein, the composite material is covered by a 35% volume fraction of an epoxy resin matrix and a 65% volume fraction of boron nitride nanosheets. Composite filler of alumina microspheres (Al 2 o 3 @BNNS) composition. where Al 2 o 3 The preparation process of @BNNS composite filler is as follows figure 1 shown in a, prepared by the following steps:

[0042] A. Liquid phase exfoliation of hexagonal boron nitride (h-BN): according to the liquid phase ultrasonic exfoliation reported in the literature (Chen, et al., Adv. Funct. Mater. 2017, 27, 1604754-1604762.) Method for preparing boron nitride nanosheets (BNNS);

[0043] B. Amination of BNNS: Add dried BNNS powder, aminosilane coupling agent APS (0.5-1wt%) and 20mL toluene solution into a 50mL round bottom flask, heat to 110-130°C and react under nitrogen protection for at least ...

Embodiment 2

[0053] This embodiment relates to a preparation method of a high thermal conductivity composite filler and the filled epoxy composite material, the composite material is covered with nitrogen by 35% volume fraction of epoxy resin matrix and 65% volume fraction of boron nitride nanosheets Composite filler (AlN@BNNS) composition of aluminum oxide microspheres. Wherein the amination preparation process of boron nitride nanosheets is the same as in Example 1, the difference is that in step C, the three-dimensional spherical filler is AlN microspheres, and a small amount of pyridine and triphenyl phosphate are also added during the epoxidation process. The ester is used as a dehydrating agent to prevent the hydrolysis reaction of AlN when it encounters water during the reaction; in step D, the aminated BNNS -APS and epoxidized AlN-GPTMS dispersed into toluene solution. Under a nitrogen atmosphere, react with gentle stirring at 120-135° C. for 4-8 hours. After the reaction, the re...

Embodiment 3

[0057] This embodiment relates to a high thermal conductivity composite filler and the silicone rubber composite material filled therewith, the composite material is covered by a 35% volume fraction of epoxy resin matrix and 65% volume fraction of graphene oxide nanosheets coated silica micro Composite filler composition of balls. Of which SiO 2 @GO composite fillers were prepared by the following steps:

[0058] A. Chemical exfoliation of graphene: According to the improved Hummer's Method reported in the literature (G.Q.Shi, et al., J.Am.Chem.Soc., 2008, 130, 5856.), graphite oxide was prepared by chemical exfoliation alkene;

[0059] B, epoxidation of graphene oxide (GO): add dried GO powder, epoxy silane coupling agent GPTMS (1~2wt%) and 20mL toluene solution in a 50mL round bottom flask, heat to 80~ The reaction was stirred at 100° C. for at least 3 h under the protection of nitrogen. After the reaction, the mixture was filtered and the solid was washed with toluene 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com