Foam type tritium breeder and a preparation method thereof

A tritium breeder, foam-type technology, which is applied in the field of nuclear fusion, can solve the problems of beryllium and breeder spheres with great differences in strength and elastic modulus, different diameters and densities of breeder spheres, and shortened available temperature window. , to achieve the effect of improving tritium multiplication performance, short tritium diffusion distance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A kind of preparation method of foam type tritium multiplying agent of the present invention, comprises the following steps:

[0058] 8a. Prepare a piece of reticulated vitreous carbon foam 5 , the parameters of the reticulated vitreous carbon foam 5 , the volume fraction of solid phase, and the pore density are preset values.

[0059] 8b. Heat the material of the proliferating agent foam 1 until it melts, and inject it into the reticulated glassy carbon foam 5 under pressure, and gradually cool down to room temperature according to the preset temperature gradient to obtain the proliferating agent foam I;

[0060] 8c. At a temperature of 500° C. to 700° C., inject oxygen into the breeder foam I to oxidize and remove the reticulated glassy carbon foam 5 in the breeder foam I to obtain the desired foam-type tritium breeder.

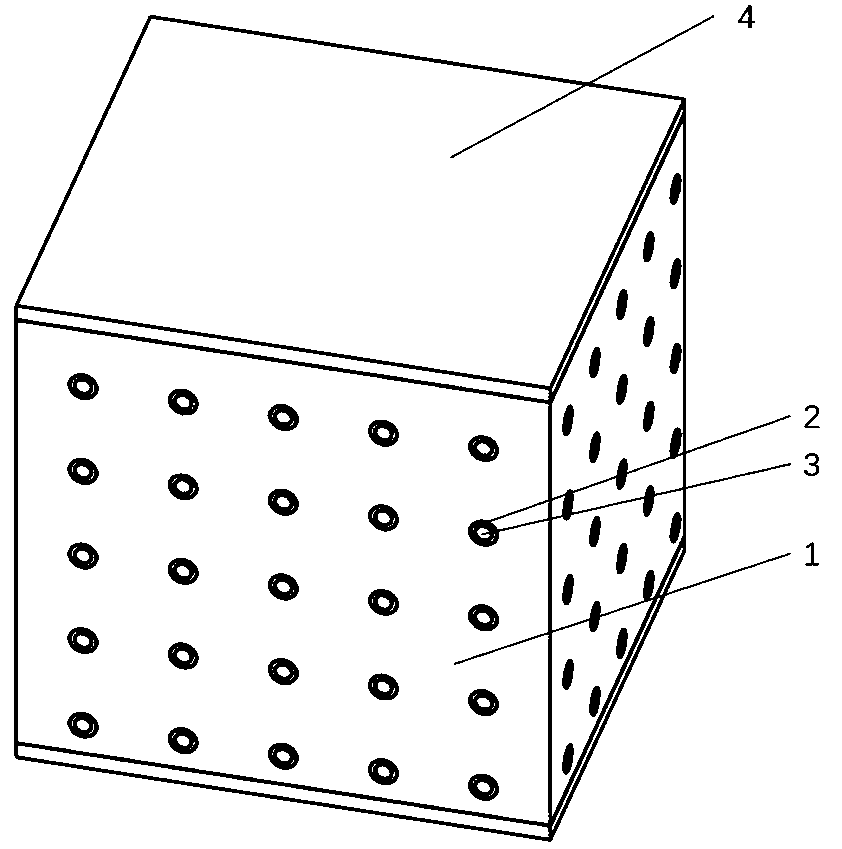

[0061] After the step 8c, there is a step 8d, and the step 8d is to generate a titanium oxide or silicon oxide skeleton 2 on the inner surface of th...

Embodiment 1

[0068] This example is used to prepare a lithium oxide foam-type tritium breeder with a size of 21mm×200mm×200mm, a pore density of 10PPI, a pore volume fraction of 5%, and a titanium oxide skeleton and an alumina buffer layer. The specific process is as follows :

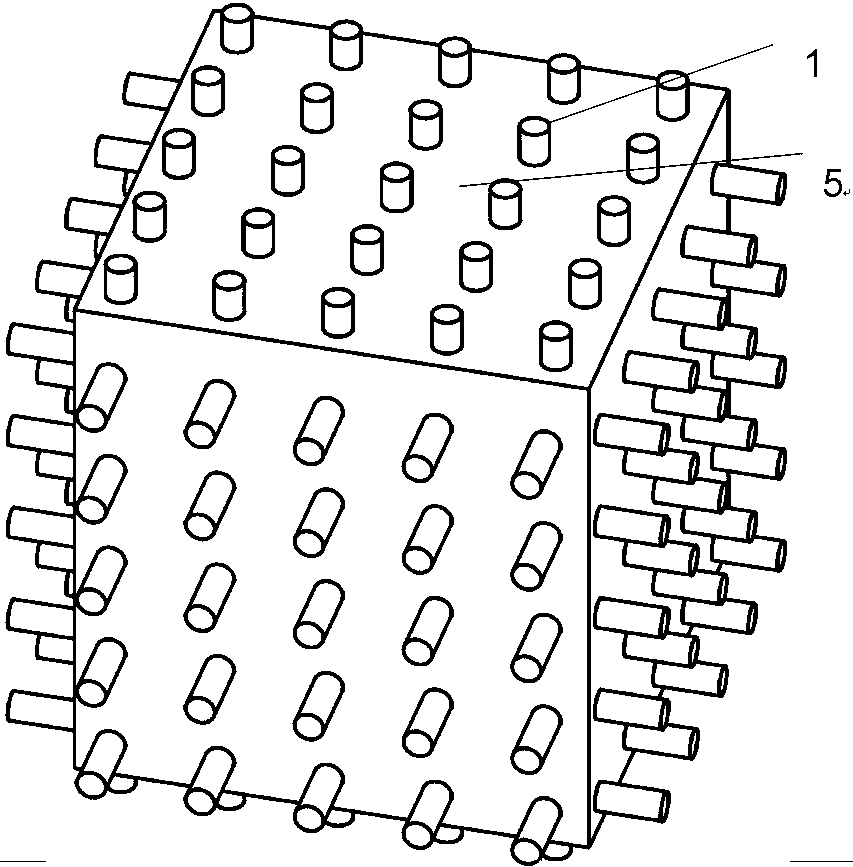

[0069] (1) Take a commercial polyurethane foam with a porosity of 10PPI, inject carbon-containing resin into it, and carbonize it at high temperature to form a reticulated glassy carbon (RVC) foam with a pore density of 10PPI and a solid phase volume fraction of 10%, such as figure 2 shown;

[0070] (2) Process the RVC foam into a cuboid of 20mm×200mm×200mm;

[0071] (3) Lithium carbonate powder with a lithium 6 abundance of 60% is heated to 1700 degrees Celsius, decomposed and melted to form liquid lithium oxide;

[0072] (4) Place the processed RVC foam in a container, then inject liquid lithium oxide into the pores of the foam through a certain pressure, and cool the lithium oxide to room temperature accordin...

Embodiment 2

[0077] This example is used to prepare a lithium oxide foam-type tritium multiplier with a size of 21mm×200mm×100mm, a pore density of 100PPI, a pore volume fraction of 40%, and a silicon oxide skeleton and a titanium oxide buffer layer. The specific process as follows:

[0078] (1) Take a commercial polyurethane foam with a porosity of 100PPI, inject a carbon-containing resin into it, and carbonize it at a high temperature to form a reticulated glassy carbon (RVC) foam with a pore density of 100PPI and a solid phase volume fraction of 35%, such as figure 2 shown;

[0079] (2) Process the RVC foam into a cuboid of 20mm×200mm×100mm;

[0080] (3) Use the chemical vapor injection method to generate a silicon oxide framework on the surface of the RVC foam, and adjust the volume fraction of the solid phase to 40%, such as Figure 8 shown;

[0081] (4) Heat lithium carbonate powder with a lithium 6 abundance of 60% to 1700 degrees Celsius, decompose and melt to form liquid lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com