A kind of titanium-doped carbon-coated sodium iron phosphate material and preparation method thereof

A carbon-coated sodium iron phosphate and titanium doping technology, applied in active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of high cost, complex operation steps, high energy consumption, and achieve reduced side reactions, The effect of fast ion transport and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 0.09mol (12.96g) FeC 2 o 4 , 0.1mol (15.6g) NaH 2 PO 4 2H 2 O, 0.022mol (7.53g) sucrose and 0.01mol (0.8g) TiO 2 Put it in a ball mill jar, add 60mL of ethanol as a dispersant, mix well, ball mill at a speed of 200r / min for 4h, and then dry in an oven at 80°C for 15h to obtain a precursor; (2) Step (1) The obtained precursor is placed in a ball mill, and ground at a speed of 150r / min for 1 hour to obtain a powdery precursor; (3) The powdery precursor obtained in step (2) is calcined at 600°C under high-purity argon 8h, Ti-doped carbon-coated NaFePO was obtained 4 Material.

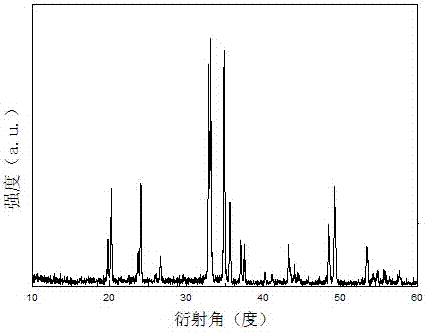

[0033] Such as figure 1 As shown, the obtained titanium-doped carbon-coated sodium iron phosphate positive electrode material has high crystallinity and complete crystal form, and what is detected is sodium iron phosphate.

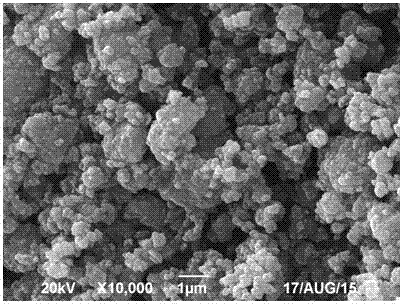

[0034] Such as figure 2 As shown, the primary particles of the obtained titanium-doped carbon-coated sodium iron phosphate positive electrode material are relati...

Embodiment 2

[0040] (1) 0.099mol (14.256g) FeC 2 o 4 , 0.1mol (15.6g) NaH 2 PO 4 2H 2 O, 0.019mol (6.5g) sucrose and 0.001mol (0.08g) TiO 2 Put it in a ball mill jar, add 120mL of ethanol as a dispersant, mix well, ball mill at a speed of 100r / min for 3h, and then dry in an oven at 60°C for 10h to obtain a precursor; (2) Step (1) The obtained precursor is placed in a ball mill, and ground at a speed of 100r / min for 0.5h to obtain a powdery precursor; (3) The powdery precursor obtained in step (2) is placed under high-purity argon at 550°C, Calcined for 6h to obtain titanium-doped carbon-coated NaFePO 4 Material.

[0041] Battery assembly: Weigh 0.24g of titanium-doped NaFePO obtained in this example 4 The material is used as the positive electrode material, adding 0.03g acetylene black (SP) as the conductive agent and 0.03g PVDF (HSV-900) as the binder, after fully grinding, add 2mL NMP to disperse and mix, mix the slurry evenly, and pull it on a 16μm thick aluminum foil Slurry was...

Embodiment 3

[0043] (1) Add 0.08mol (11.52g) FeC 2 o 4 , 0.1mol (15.6g) NaH 2 PO 4 2H 2 O, 0.0263mol (9.0g) sucrose and 0.02mol (1.6g) TiO 2 Put it in a ball mill jar, add 90mL ethanol as a dispersant, mix evenly, ball mill at a speed of 300r / min for 7h, and then dry in an oven at 90°C for 24h to obtain a precursor; (2) Step (1) The obtained precursor is placed in a ball mill, and ground at a speed of 200r / min for 2 hours to obtain a powdery precursor; (3) The powdery precursor obtained in step (2) is calcined at 650°C under high-purity argon 10h, Ti-doped carbon-coated NaFePO 4 Material.

[0044] Battery assembly: Weigh 0.24g of titanium-doped NaFePO obtained in this example 4 The material is used as the positive electrode material, adding 0.03g acetylene black (SP) as the conductive agent and 0.03g PVDF (HSV-900) as the binder, after fully grinding, add 2mL NMP to disperse and mix, mix the slurry evenly, and pull it on a 16μm thick aluminum foil Slurry was used to make the positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com