Preparation method of anticorrosive and abrasion-resistant layer of machine barrel

An anti-corrosion and wear-resistant, barrel technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of easy corrosion of the barrel, affecting the service life of the wear-resistant layer, etc. smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

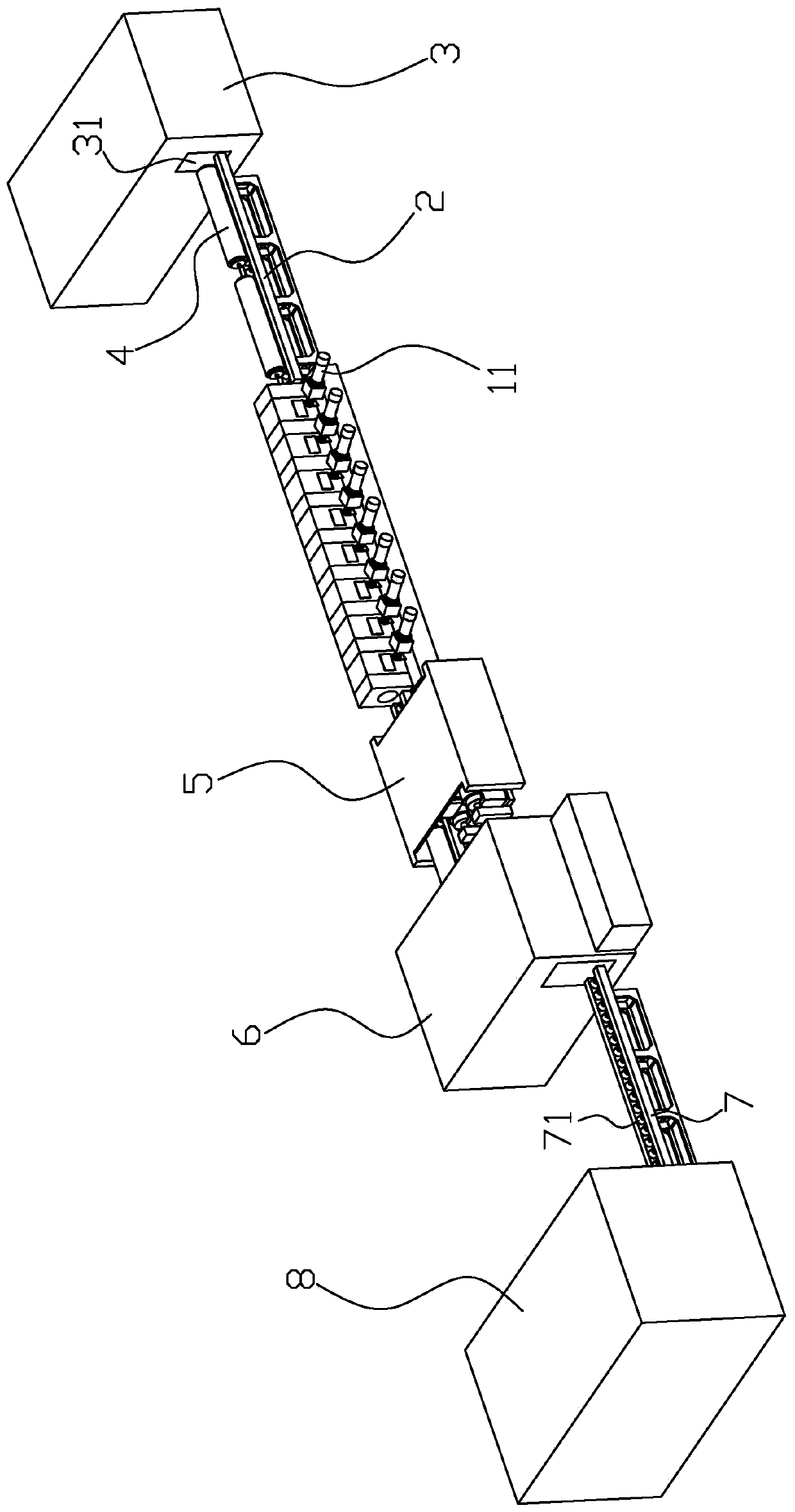

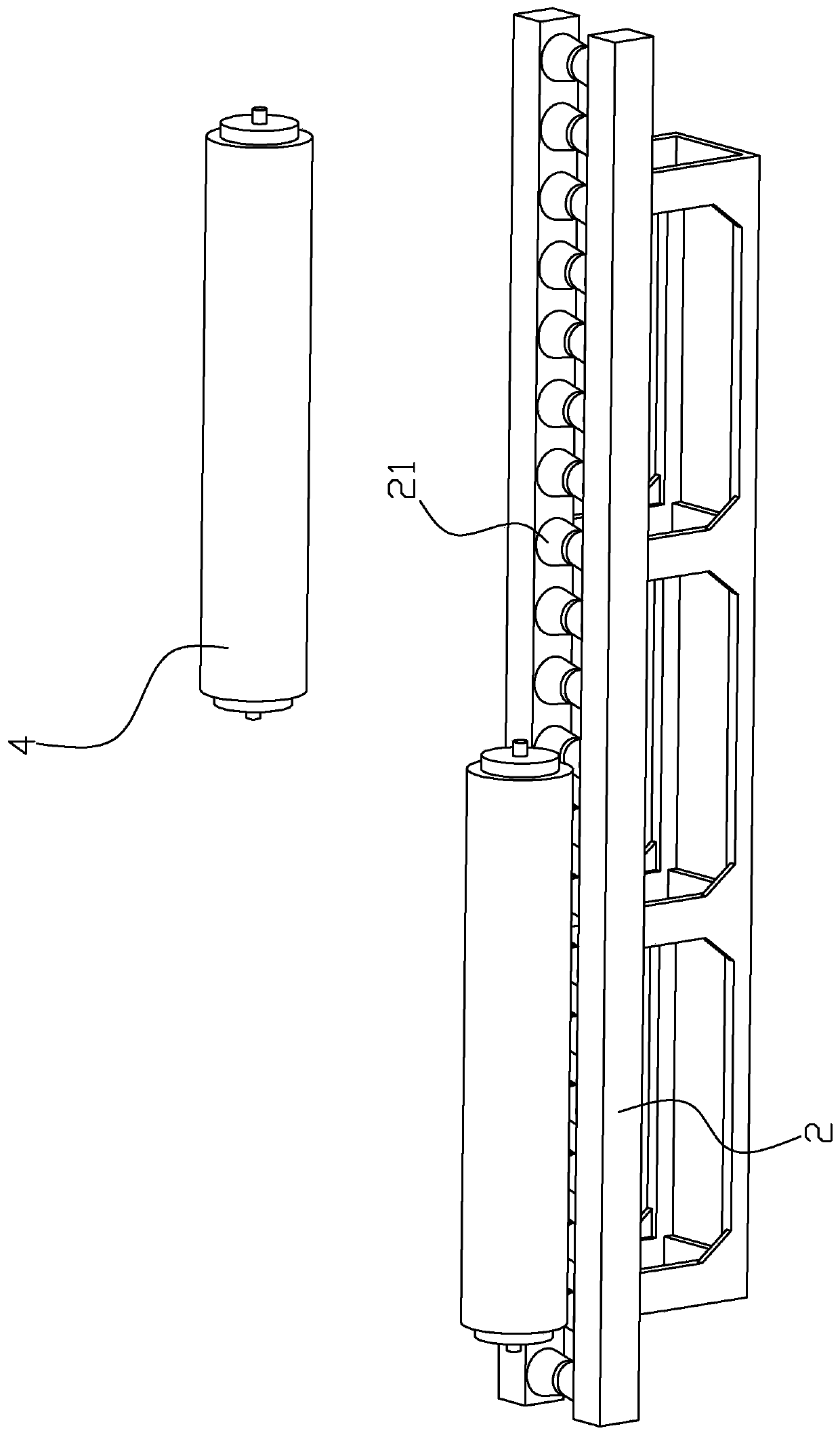

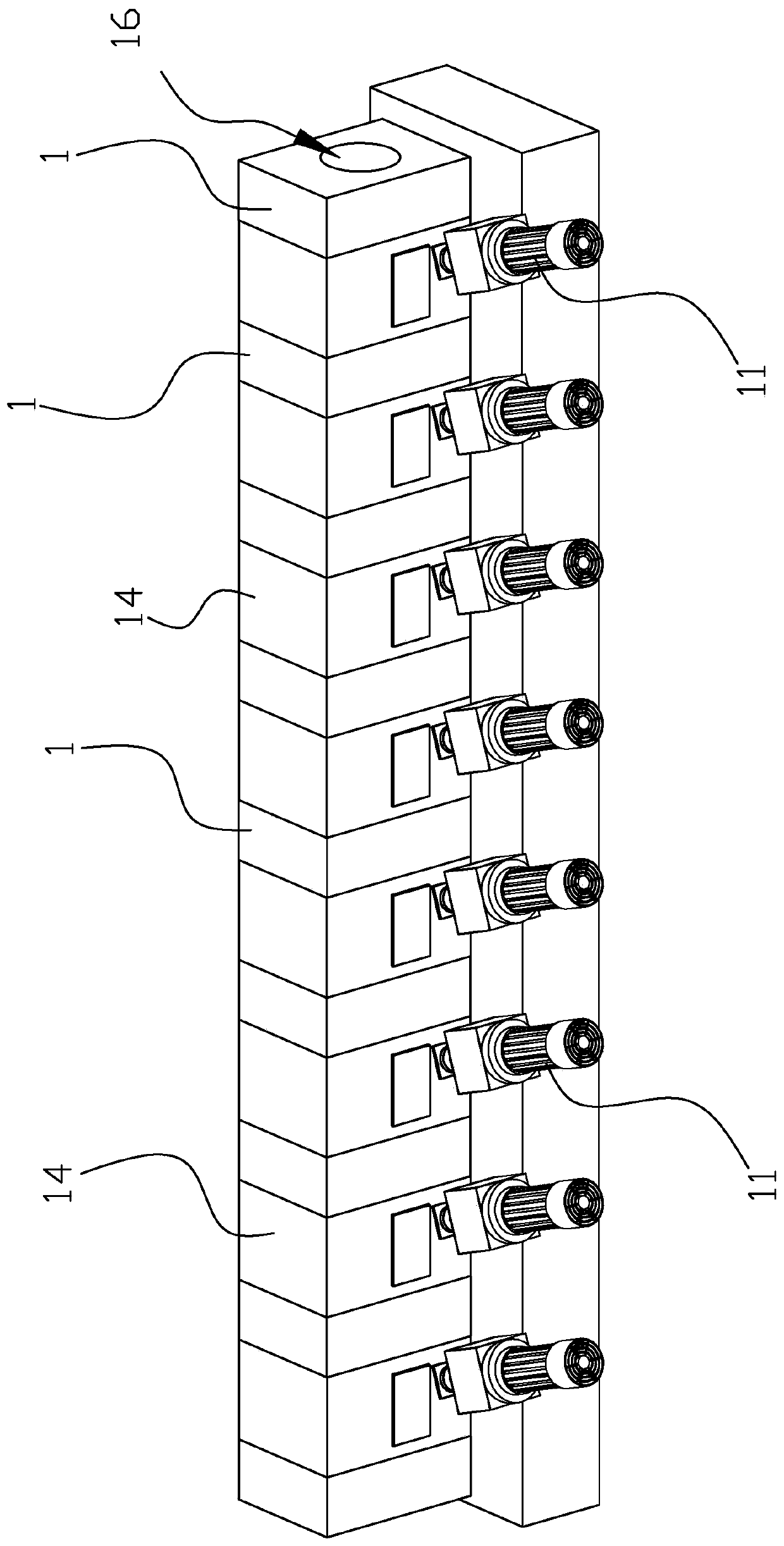

[0031] Such as Figure 1 to Figure 10 As shown, the preparation method of the machine barrel anti-corrosion and wear-resistant layer of the present embodiment comprises the following steps,

[0032] 1. Put the nickel-based spherical tungsten carbide alloy powder in the inner cavity of the machine barrel, and seal the openings at both ends of the machine barrel after the nickel-based spherical tungsten carbide alloy powder is placed;

[0033] 2. Place the barrel 4 with both ends closed in a heating furnace with a temperature of 1000-1300°C for heating. When the barrel 4 is heated in the heating furnace, keep the radial rotation and keep moving back and forth in the axial direction. When the inner cavity of the barrel After the nickel-based spherical tungsten carbide alloy powder is evenly melted in the inner cavity of the barrel, with the radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com