Core-shell SiO2@rosin-based polymer microspheres and preparation method thereof

A technology of polymer microspheres and core-shell type, which is applied in the field of high performance liquid chromatography, can solve the problems of low theoretical plate number of chromatographic columns, narrow range of mobile phase selection, wide particle size distribution of microspheres, etc., and achieve pore structure Rich, good separation performance, high solvent tolerance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

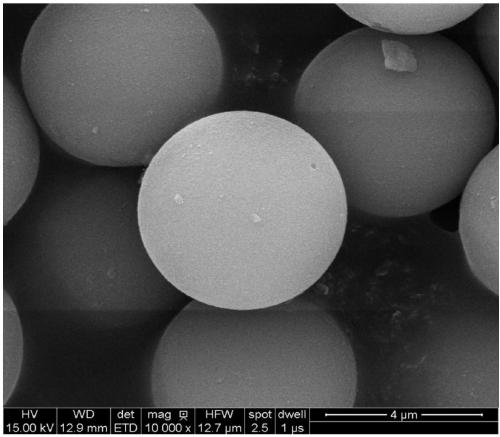

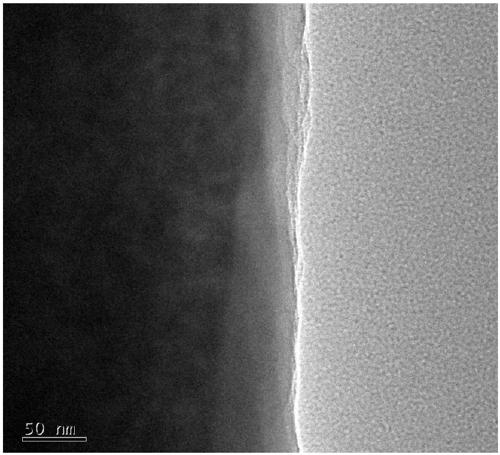

[0034] First 1.0g maleopimaric acid ethylene glycol acrylate, 1.0g methacrylic acid and 0.1g azobisisobutyronitrile are mixed uniformly to obtain the material for coating, and then the material for coating is evenly coated to 20.0 g silica gel surface, and then placed in 100 mL of 1% sodium lauryl sulfate aqueous solution for free radical polymerization for 6 hours, then Soxhlet extracted the product with absolute ethanol, and then vacuum dried to obtain the core-shell Type SiO 2 @ Rosin-based polymer microspheres.

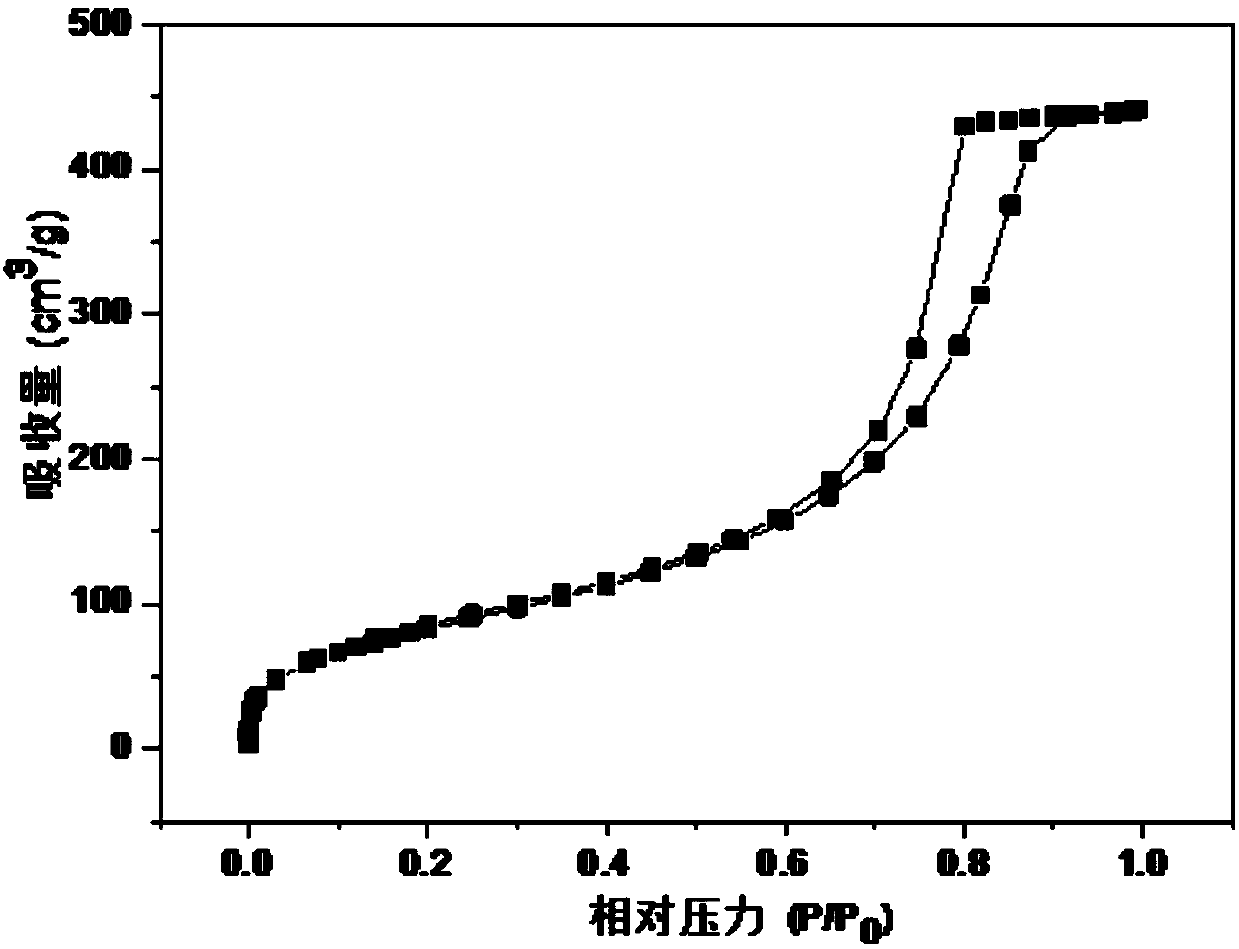

[0035] After detection and analysis, the core-shell type SiO obtained in this embodiment 2 The particle size distribution of @rosin-based polymer microspheres is concentrated in the range of 80-120μm, the average pore size is 6.5nm, and the specific surface area is 350m 2 / g.

preparation Embodiment 2

[0037] First 50g maleopimaric acid ethylene glycol acrylate, 200g acrylic acid and 5g azobisisoheptanonitrile are mixed uniformly to obtain the material for coating, then the material for coating is evenly coated on the surface of 250g silica gel, and then placed Carry out radical polymerization reaction in 1000mL of 5% sodium dodecyl sulfate aqueous solution for 7h, then Soxhlet extract the product with absolute ethanol, and then vacuum dry to obtain core-shell SiO 2 @ Rosin-based polymer microspheres.

[0038] After detection and analysis, the core-shell type SiO obtained in this embodiment 2 The particle size distribution of @rosin-based polymer microspheres is concentrated in the range of 200-250μm, the average pore size is 0.5nm, and the specific surface area is 293m 2 / g.

preparation Embodiment 3

[0040]First mix 10g ethylene glycol maleopimarate, 50g methyl methacrylate and 1.5g azobisisobutyronitrile evenly to obtain a coating material, and then evenly coat the coating material to 2000g Silica gel surface, and then placed in 1000mL of 15% sodium lauryl sulfate aqueous solution for free radical polymerization reaction for 9h, then Soxhlet extraction of the product with absolute ethanol, and then vacuum drying to obtain the core-shell SiO 2 @ Rosin-based polymer microspheres.

[0041] After detection and analysis, the core-shell type SiO obtained in this embodiment 2 The particle size distribution of @rosin-based polymer microspheres is concentrated in the range of 2-14μm, the average pore size is 26.01nm, and the specific surface area is 312m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com