Ultraviolet shielding film

An external shielding and film technology, applied in the field of UV shielding films, can solve the problems of poor stability and durability of UV shielding films, and achieve improved stability and durability, good thermal and mechanical properties, and high reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

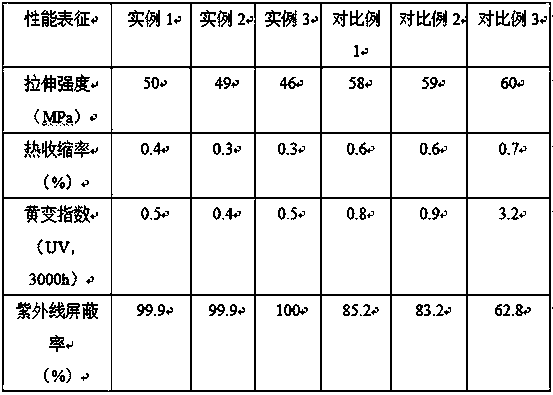

Examples

preparation example Construction

[0031] The preparation method of composite resin base material, comprises the steps:

[0032] (1) Take gallic acid, epoxidized soybean oil, and epichlorohydrin in a reaction kettle according to a mass ratio of 3:1~2:16~30, mix them in a reactor, heat up to 85~95°C, and keep stirring at a speed of 350~600r / min for 40 ~60min, to get the mixed solution, take the mixed solution and add 1~4% additives of the mixed solution mass to mix, keep stirring at 550~900r / min for 2~4h, then cool down to room temperature naturally, get the working solution, take the working solution and add mass Adjust the pH to 7.3-8.0 with a 12% NaOH solution, add 6-10% pretreated nano-materials as the working solution, mix and stir, let stand at room temperature for 1-3 hours, filter, take the filter cake and wash it with water 2-4 times to obtain resin base;

[0033] (2) Take the resin base material according to the mass ratio of 3:0.2~0.5:12~20, add auxiliary materials and reagent A, mix and stir to obta...

example 1

[0040] Pretreatment nano material: take nano TiO according to the mass ratio of 3:1:3 2 , Nano ZnO, Nano SiO 2 Mix in a mortar and grind for 1 hour at 400r / min to obtain a grinding base. Take the grinding base and add hexadecyltrimethylammonium bromide and water in a mass ratio of 5:1:12, mix it with water, and ultrasonically treat it at a frequency of 55kHz for 20min. have to pretreat nanomaterials.

[0041] Reagent A: Mix ammonium chloride solution with a mass fraction of 15% and sodium bicarbonate at a mass ratio of 12:1 to obtain reagent A.

[0042] Reagent B: Mix Tris-HCl buffer solution with a pH of 7.8 and absolute ethanol at a volume ratio of 12:5 to obtain Reagent B.

[0043] Auxiliary material: mix polyvinylpyrrolidone and nano-hydroxyapatite at a mass ratio of 3:0.1 to obtain the auxiliary material.

[0044] Additive: Mix tetrabutylammonium bromide and triphenylphosphine in a mass ratio of 5:1 to obtain the additive.

example 2

[0056] Pretreatment nano material: take nano TiO according to the mass ratio of 3:1:4 2 , Nano ZnO, Nano SiO 2 Mix in a mortar and grind for 2 hours at 550r / min to obtain a grinding base. Take the grinding base and add hexadecyltrimethylammonium bromide and water in a mass ratio of 5:2:12, mix it with water, and ultrasonically treat it at 60kHz for 32min. have to pretreat nanomaterials.

[0057] Reagent A: Mix ammonium chloride solution with a mass fraction of 15% and sodium bicarbonate at a mass ratio of 15:1 to obtain reagent A.

[0058] Reagent B: Mix Tris-HCl buffer solution with a pH of 8.0 and absolute ethanol at a volume ratio of 15:5 to obtain Reagent B.

[0059] Auxiliary material: mix polyvinylpyrrolidone and nano-hydroxyapatite at a mass ratio of 4.5:0.1 to obtain the auxiliary material.

[0060] Additive: Mix tetrabutylammonium bromide and triphenylphosphine in a mass ratio of 5:2 to obtain the additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com