A method for preparing cubic pyrochlore structured nanoparticles based on a sol-gel process and applications of the nanoparticles

A cubic pyrochlore, nanoparticle technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low mechanical strength of fluoride, limited application of anti-laser damage, poor chemical stability, etc., and achieves a simple, feasible and simplified preparation method. Double-doping or multi-doping process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of the cubic pyrochlore structure nano-particle based on sol-gel method of the present invention, comprises the following steps:

[0033] S1, using 10-100ml acetic acid as a solvent and as solution A;

[0034] S2, under the condition of fast stirring, be (1~9):1 mass ratio bismuth nitrate and erbium nitrate to join in solution A rapidly, and obtain solution B;

[0035] S3. Under rapid stirring, tetrabutyl titanate with a mass ratio of (0.1-0.2): 1 to the above solution is quickly added to solution B to obtain solution C;

[0036] S4. Put the solution C in a water bath at a temperature of 10-18° C. and add 13-15 mL of ammonia water to adjust the pH value of the solution to neutral to obtain a milky white solution D;

[0037] S5. Control the centrifugal rate to 5000-10000 rpm, and centrifuge the milky white solution D to obtain white powder E;

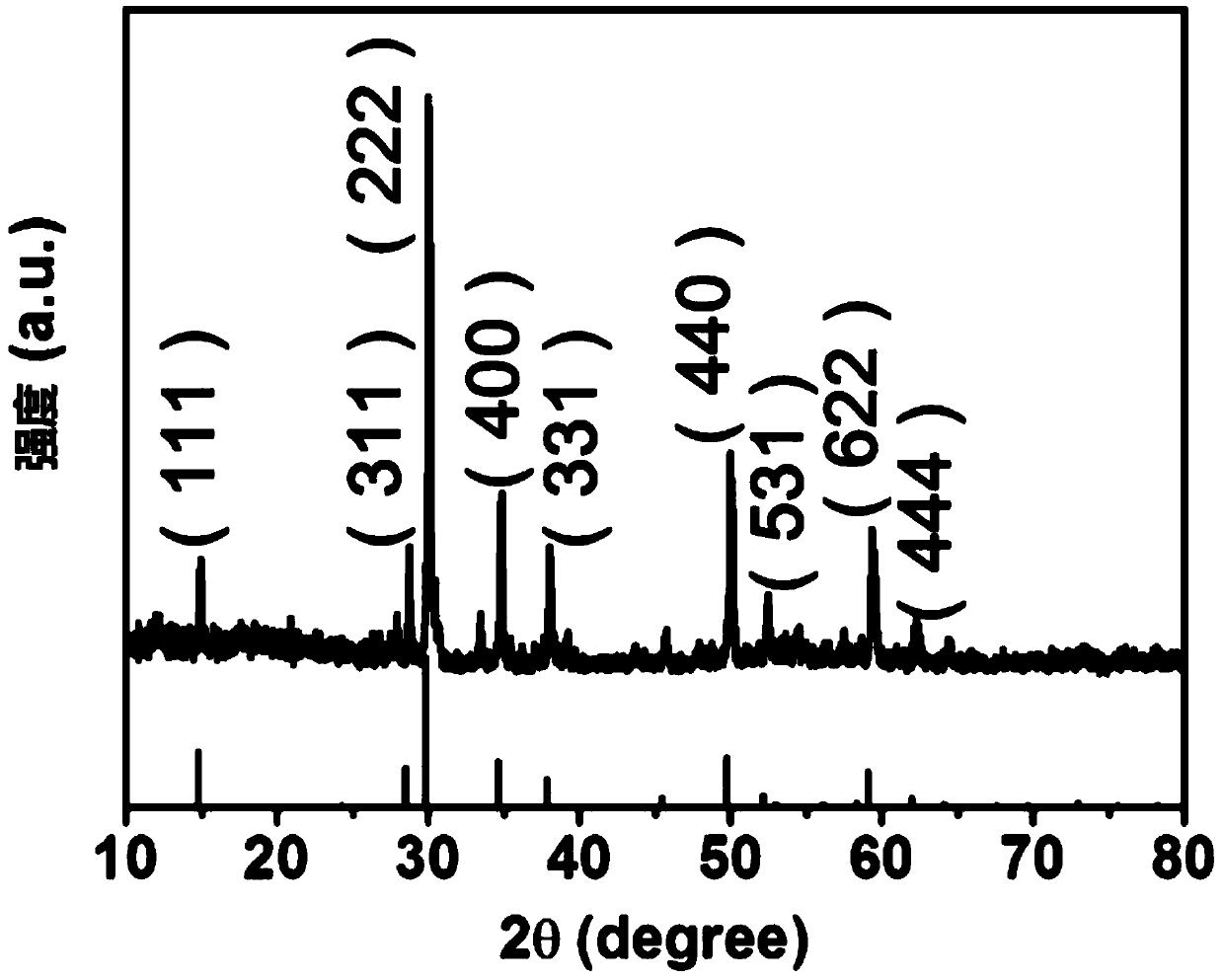

[0038] S6. Dry powder E at 80°C for 6-12 hours, and then calcine at 650-900°C to obtain Bi 2 Ti ...

Embodiment 1

[0044] Dissolve bismuth nitrate and erbium nitrate in 10 ml of acetic acid at a mass ratio of 1:1, and form a transparent solution by magnetic stirring in a water bath; adjust the temperature of the water bath to 10°C, and slowly add 13 ml of ammonia water to the transparent solution In the solution, a milky white product is produced, and the pH of the whole system is neutral, and the reaction is completed. Subsequently, the reacted solution was subjected to solid-liquid separation with a centrifuge at a centrifugation rate of 5000 rpm to obtain a white powder. The white powder was dried at 80°C for 6 hours, then transferred to a muffle furnace and calcined at 800°C for 1 hour to obtain Bi 2 Ti 2 o 7 : Er nano powder.

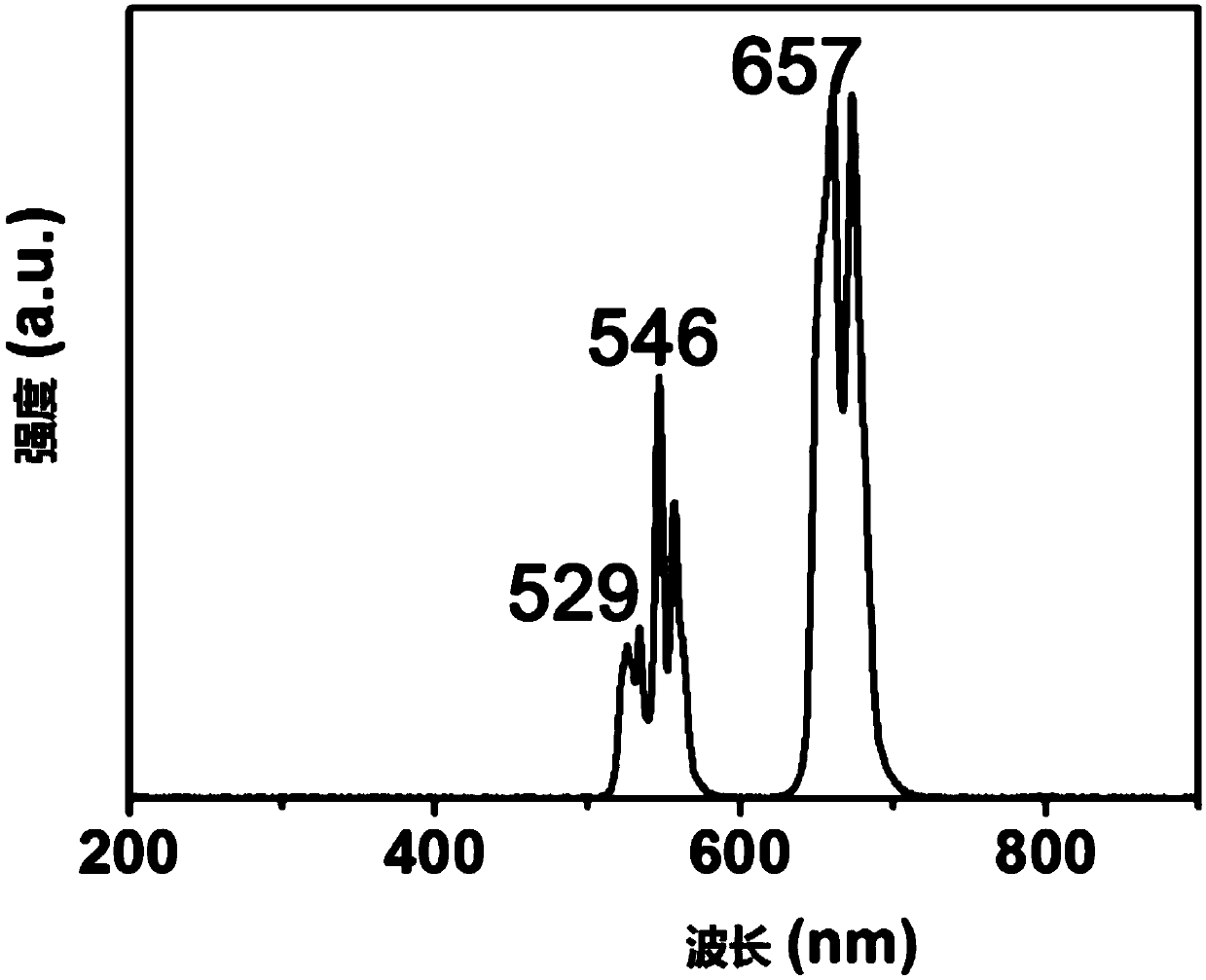

[0045] figure 1 The near-infrared light source with a wavelength of 980nm is given as the excitation source, and the obtained up-conversion luminescence performance is obtained. The test wavelength range is 200-900nm, and the integration time is 10ms. It ...

Embodiment 2

[0047] Dissolve bismuth nitrate and erbium nitrate in 40 ml of acetic acid at a mass ratio of 9:1, and form a transparent solution by magnetic stirring in a water bath; adjust the temperature of the water bath to 12°C, and slowly add 15 ml of ammonia water to the transparent solution In the solution, a milky white product is produced, and the pH of the whole system is neutral, and the reaction is completed. Subsequently, the reacted solution was subjected to solid-liquid separation with a centrifuge at a centrifugation rate of 8000 rpm to obtain a white powder. The white powder was dried at 80°C for 8 hours, then transferred to a muffle furnace and calcined at 800°C for 1 hour to obtain Bi 2 Ti 2 o 7 : Er nano powder.

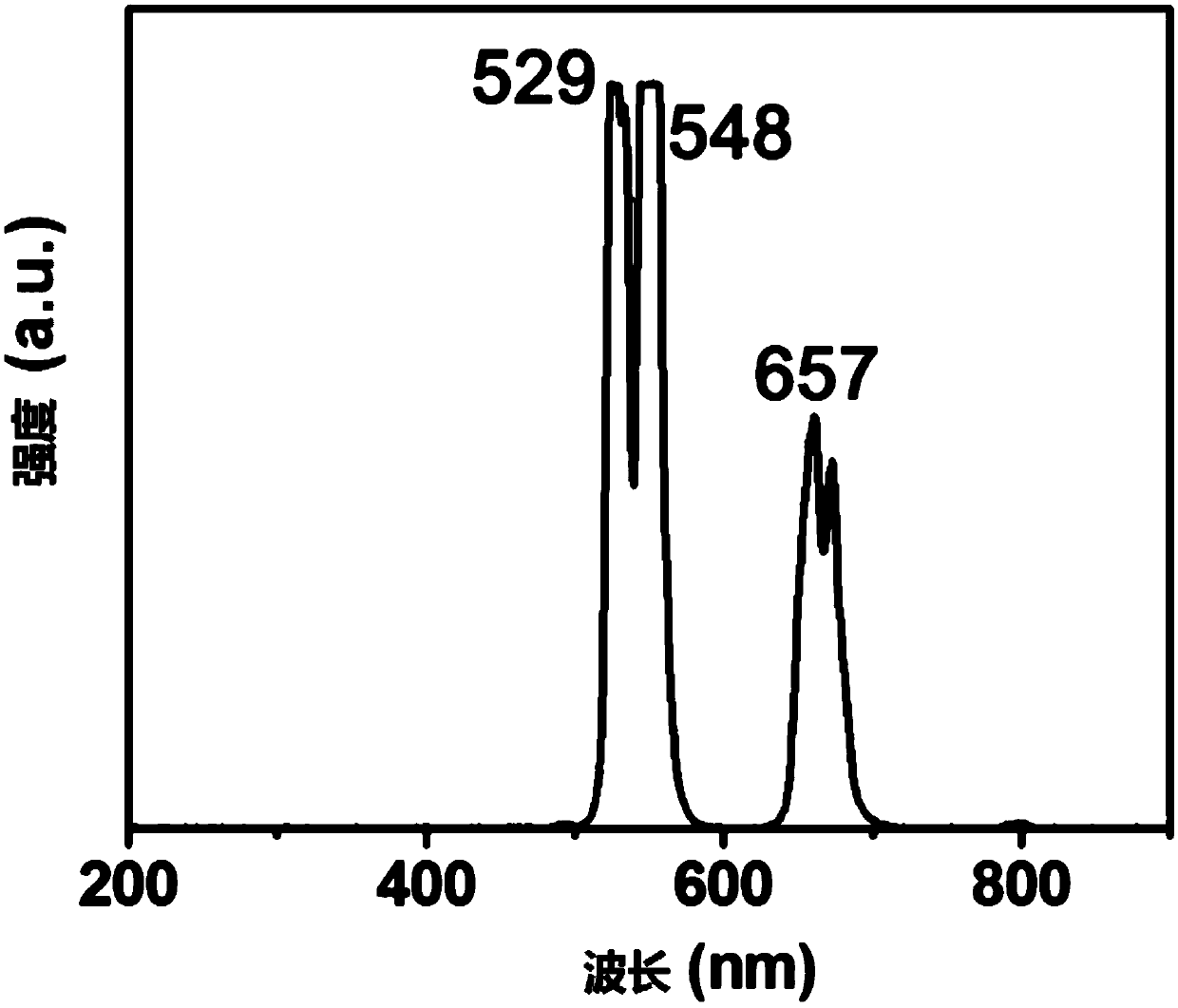

[0048] figure 2 Given that the laser with a wavelength of 980nm is used as the excitation source, the obtained up-conversion luminescence performance is obtained. The test wavelength range is 200-900nm, and the integration time is 10ms. It can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com