A kind of niobium steel clad plate and its preparation method

A composite board and niobium steel technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of high production site requirements, high production noise, waste gas pollution, etc., and achieves low production site requirements. High processing efficiency and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

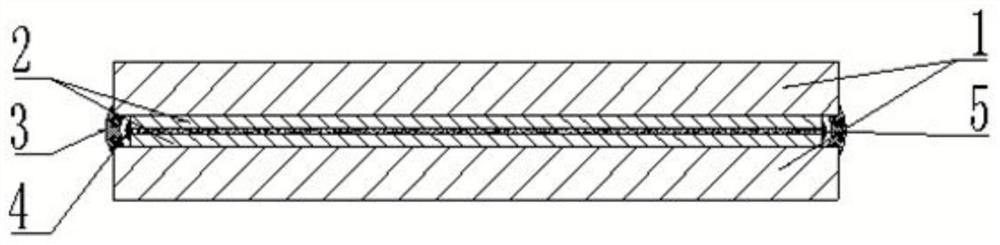

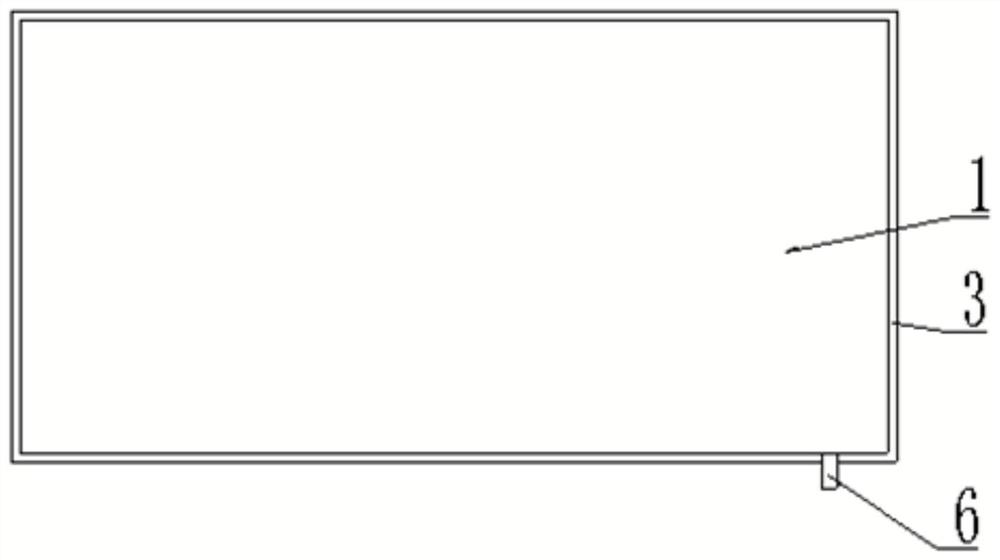

[0027] A preparation method of a niobium steel clad plate mainly comprises the following steps: material selection - surface treatment - application of release agent - welding niobium plate - forming blank (sealing and welding periphery - welding vent pipe - air tightness inspection - vacuuming - filling inert gas )—heating—rolling—heat treatment—leveling—edge trimming—surface treatment—finished composite sheet.

[0028] The preparation method of the niobium steel clad plate specifically includes the following steps:

[0029] Step (1) selecting a carbon steel plate with a thickness of 100mm and a niobium plate with a thickness of 10mm, and grinding the surfaces to be bonded between the niobium plate and the steel plate, so that the surfaces to be bonded are free of oxide layers, impurities and voids, and present a fresh metal surface;

[0030] Step (2) To prepare a release agent, take alumina powder and polyvinyl chloride powder with a mesh number greater than 200 meshes and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com