A method for suppressing cyanide dissolution of copper minerals in refractory copper-bearing gold ores

A technology for refractory and gold mines, applied in the direction of improving process efficiency, etc., to achieve the effects of improving utilization rate, reducing cyanide consumption, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

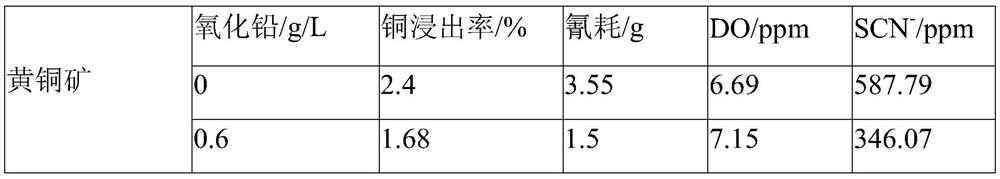

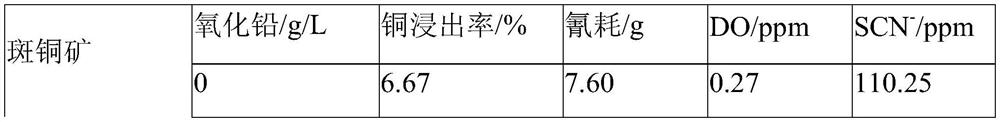

[0021] In this embodiment, two single minerals, chalcopyrite and bornite, are treated by the method of the present invention. Grind the above two kinds of copper minerals with a three-head grinder to -200 mesh and account for 100%, respectively take a certain amount of two kinds of copper minerals (the amount of copper metal is 5g), press the liquid-solid ratio 27:1, pH=11.5 , NaCN concentration 5g / L, stirring speed 901r / min, leaching temperature 25°C, leaching time 12h for leaching test. The test results are shown in the table below.

[0022]

[0023]

[0024]

[0025] As can be seen from the above table, the addition of 0.6g / L of lead oxide reduces the leaching rate of chalcopyrite copper from 2.4% when no lead oxide is added to 1.68%, and the leaching rate of bornite copper is reduced from 2.4% when no lead oxide is added. 6.67% was reduced to 2.33%, which indicated that the addition of lead oxide inhibited the dissolution of chalcopyrite and bornite in the cyanid...

Embodiment 2

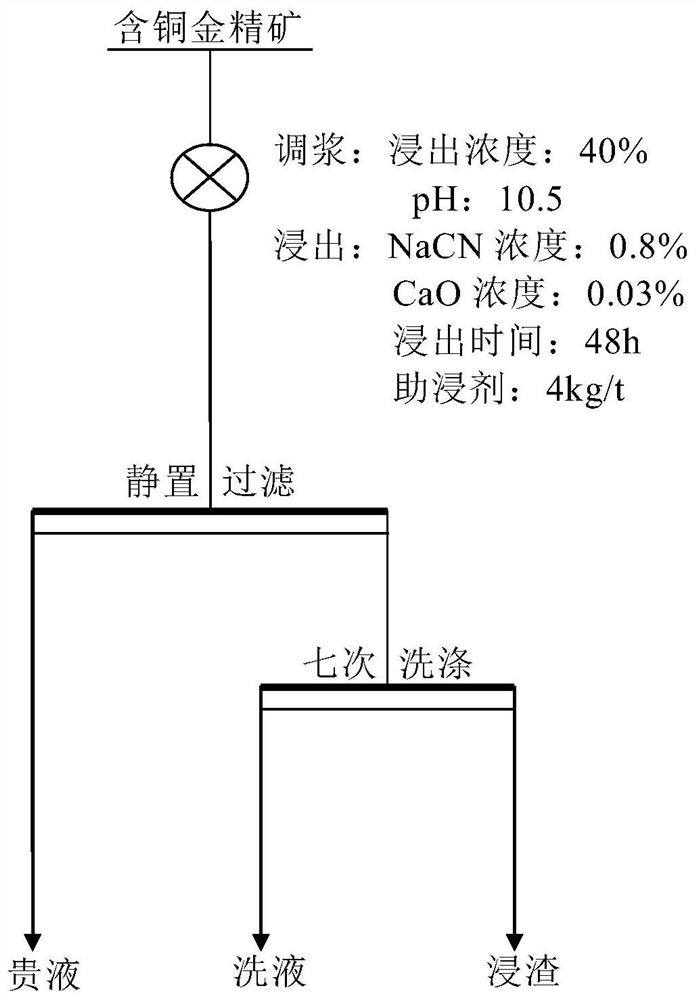

[0027] In this embodiment, the method of the present invention is used to treat a copper-containing gold concentrate in Lingbao, Henan. The main metal minerals in the copper-bearing gold concentrate are chalcopyrite, sphalerite and pyrite, the main gangue minerals are quartz and muscovite, and the gold and copper grades are 38.97g / t and 2.35% respectively. test attached figure 1 Carried out, the test results are shown in the table below.

[0028] Lead oxide / kg / t Gold leaching slag / g / t Gold leaching rate / % Copper leaching rate / % Sodium cyanide unit consumption / kg / t 0.0 3.94 89.9 33.19 19.28 4.0 2.91 92.53 27.66 15.88

[0029] It can be seen from the above table that the addition of 4.0kg / t of lead oxide reduces the copper leaching rate from 33.19% to 27.66% when no lead oxide is added, and the gold leaching rate increases from 89.90% when no lead oxide is added to 92.53%, and the cyanide consumption is also reduced from 19.28kg / t without ...

Embodiment 3

[0031] In this embodiment, the method of the present invention is used to treat three kinds of copper-containing gold concentrates in Fujian (respectively A mine, B mine and C mine). The metal minerals in these three kinds of copper-bearing gold concentrates are mainly pyrite, with a roughly content of about 40%, followed by chalcopyrite, galena, pyrrhotite, and copper blue and tetrahedrite, sphalerite. Zinc ore and trace lead sulfur salt minerals. The gangue minerals are mainly quartz, with a content of about 35%, followed by sericite (white) mica (about 15-25%), and the rest are chlorite (about 5-10%), kaolinite and calcite, a small amount of feldspar, etc. , There are silver minerals (natural silver and argentite, etc.) when there is obvious presence of carbon. The grades of gold and copper in mine A, mine B and mine C are 115.2g / t, 2.48%, 51.8g / t, 1.89%, 109.2g / t, 0.48%, respectively.

[0032] Routine test conditions: leaching time is 48 hours, leaching sodium cyanide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com