A method for rapid electrodeposition coating on the surface of magnesium alloy

A magnesium alloy and electrodeposition technology, applied in the field of metal surface treatment, can solve problems such as environmental pollution and complex pretreatment, and achieve the effects of simplifying the electroplating process, simplifying the electroplating process and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

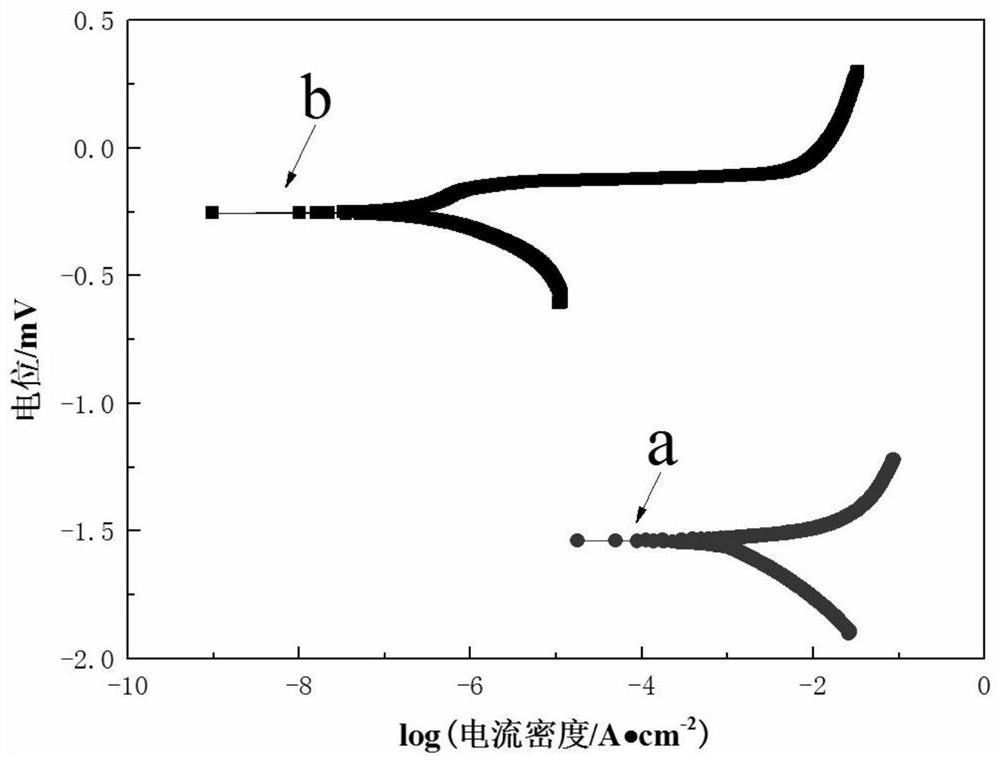

[0035] Due to the high chemical activity of the magnesium alloy, the reaction is violent in the acidic bath with a pH of 4, and cannot be directly electroplated. The present invention adopts a rapid electrodeposition method to deposit a nickel-molybdenum alloy coating on the surface of the magnesium alloy. The specific steps are as follows:

[0036] 1. Sand blast the surface of the magnesium alloy and place it in absolute ethanol for ultrasonic cleaning. The working gas for sand blasting is compressed air with a pressure of 0.4-0.6 MPa;

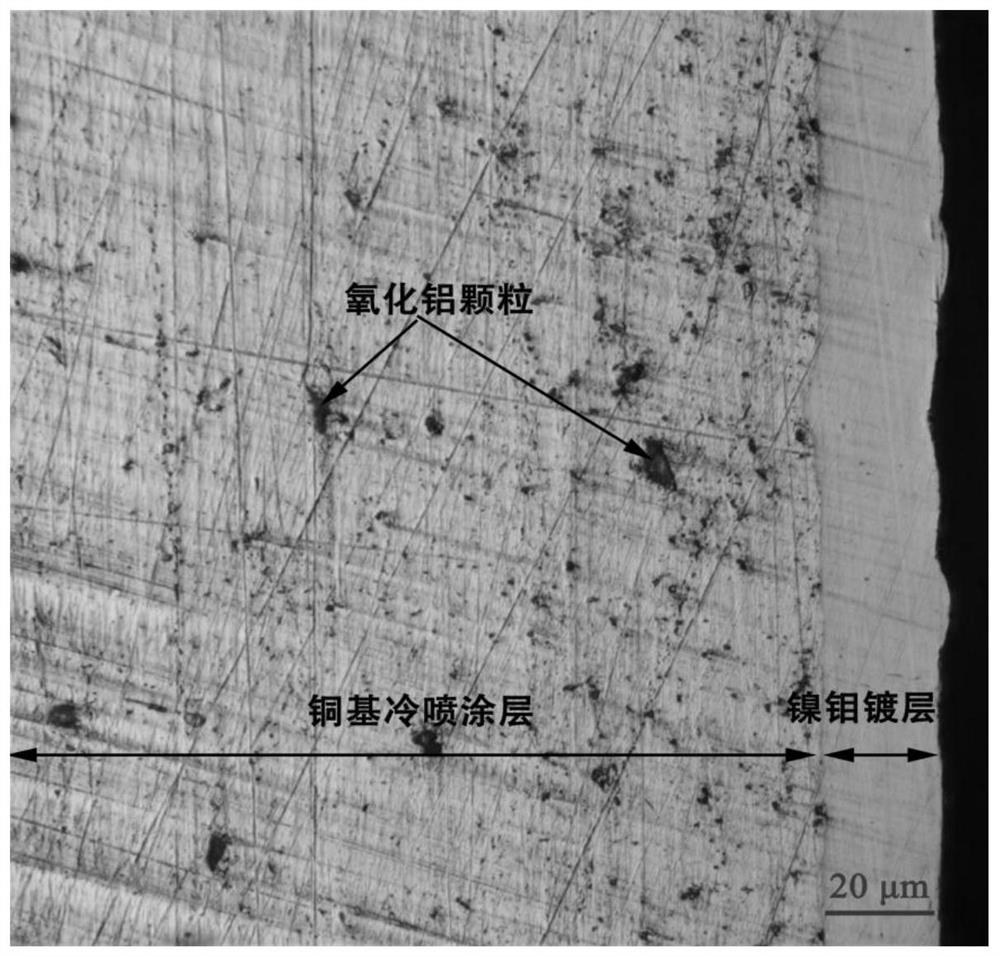

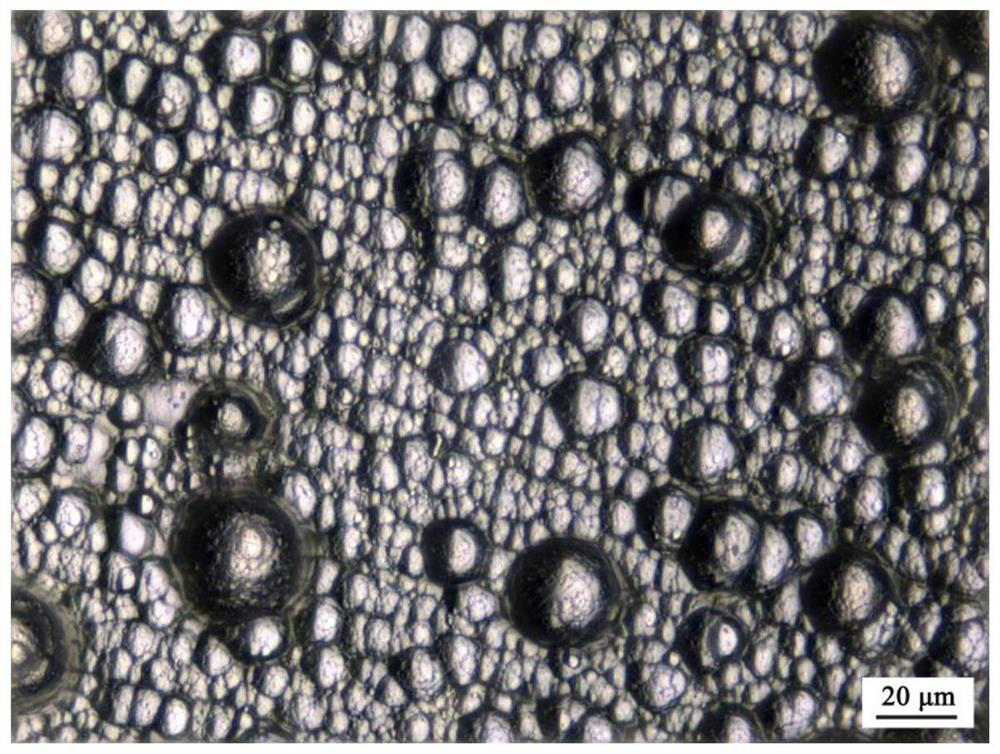

[0037] 2. Prepare a cold spray coating on the surface of the magnesium alloy after sandblasting by cold spraying. The coating material is a mechanically mixed powder of dendritic copper powder and irregular alumina powder, wherein the mass fraction of alumina powder 20%, the cold spraying gas preheating temperature is 600°C, the powder feeding rate is 25g / min, and the powder feeding distance is 10mm, so that the surface of the magnesium alloy ...

Embodiment 2

[0046] Adopt rapid electrodeposition method to prepare cobalt coating on the surface of magnesium alloy, its specific steps are as follows:

[0047] 1. Sand blast the surface of the magnesium alloy and place it in absolute ethanol for ultrasonic cleaning. The working gas for sand blasting is compressed air with a pressure of 0.6 MPa;

[0048] 2. Prepare a cold spray coating on the surface of the magnesium alloy after sandblasting by cold spraying. The coating material is a mechanically mixed powder of dendritic copper powder and irregular alumina powder, wherein the mass fraction of alumina powder 20%, the cold spraying gas preheating temperature is 600°C, and the powder feeding distance is 10mm, so that the surface of the magnesium alloy forms a cold sprayed copper-based coating;

[0049] 3. Place the cold-sprayed copper-based coating in the electroplating solution (CoSO with a concentration of 110g / L 4 ·6H 2 O, Na with a concentration of 100g / L 2 SO 4 , with a concentrat...

Embodiment 3

[0052] Different from Example 1 in that: the electroplating solution described in step 3 is 60g / L NiSO 4 ·6H 2 O, 75g / L Na 3 C 6 h 5 o 7 2H 2 O, 5g / L Na 2 MO 4 2H 2 O, 35g / L NiCl 2 , 25g / L of H 3 BO 3 , 1g / L sodium saccharin, 0.1g / L sodium lauryl sulfate; the parameters of the electroplating are: the duty cycle of the power pulse signal is 18%, and the average current density is 5A / dm 2 , the temperature is 25°C, and the pole spacing of the electrodes is 15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com