A soft lead-free low-temperature sealing glass and its preparation method

A sealing glass and low-temperature technology, which is applied in the field of lead-free soft low-temperature sealing glass and its preparation, can solve the problems of high cost and achieve the effects of low production cost, inhibition of glass crystallization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the soft lead-free low-temperature sealing glass specifically includes the following operations:

[0027] 1) Ingredients and mixing; Weigh each component raw material according to the ratio, put it into a ball mill tank and mix it evenly;

[0028] 2) Melting: Melt the prepared material at 800-1100°C and keep it warm for 0.5-3 hours; quench the melted glass to obtain glass frit;

[0029] 3) Grinding and granulation: crushing, grinding, and sieving glass frit to obtain glass powder; mixing glass powder with binder, dispersant and solvent to form a slurry, drying and granulating to obtain a particle size of 100-200 mesh Granulated glass powder;

[0030] 4) Pressing and sintering; use a tablet press to press the granulated powder into the desired shape, and heat up at a rate of 1-5°C / min, keep warm at 300-400°C for 2-5 hours to remove the glue, and then use a 5- Raise the temperature at a rate of 10°C / min to 370-450°C for 0.5-2 hours for sinterin...

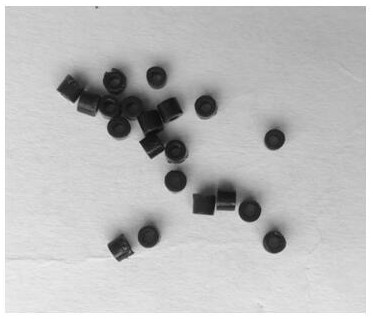

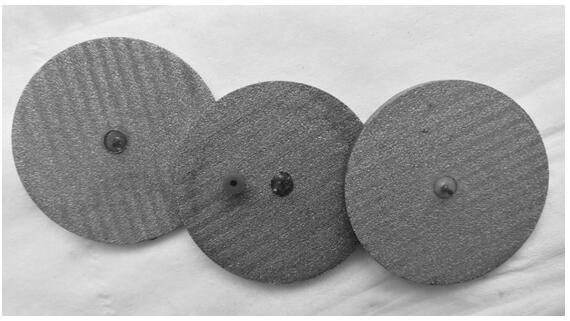

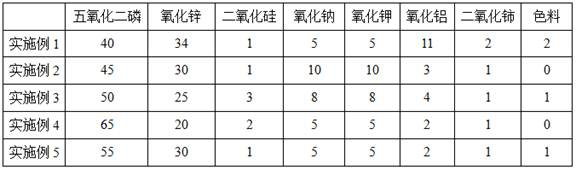

Embodiment 1

[0038] Weigh a certain amount of raw materials according to the ratio in Table 1. According to the preparation method of the present invention, it is melted at 1100° C. for 1 hour and then quenched to obtain a glass block, which is pulverized, ground and granulated. The molded pressed parts are heated to 350°C at a rate of 1°C / min and held for 4 hours to remove the glue, and then heated to 430°C at a rate of 5°C / min for 1 hour and sintered to obtain a spare preform such as figure 1 shown. Place the prefab in such as figure 2 In the aluminum alloy sealing device perforated in the middle, the prefabricated part is a hollow cylindrical glass bead, and the Kovar alloy needle is put into the glass bead, and the temperature is raised in an electric furnace at a rate of 10°C / min, and the temperature is kept at 520°C for 0.5 hours. Cool down to room temperature at a rate of 2°C / min to complete the sealing. figure 2 The sealing part on the left is the sample diagram of Example 1 a...

Embodiment 2

[0040]Weigh a certain amount of raw materials according to the ratio in Table 1. According to the preparation method of the present invention, it is melted at 1000° C. for 1 hour and then quenched to obtain a glass block, which is pulverized, ground and granulated. The molded pressed parts were heated at a rate of 1 °C / min to 350 °C for 4 hours for debinding, and then heated at a rate of 5 °C / min to 370 °C for 1 hour for sintering. Place the prefab in such as figure 2 In the aluminum alloy sealing device perforated in the middle, the prefabricated part is a hollow cylindrical glass bead, and the Kovar alloy needle is put into the glass bead, and the temperature is raised in an electric furnace at a rate of 10°C / min, and the temperature is kept at 480°C for 0.5 hours , cooling down to room temperature at a rate of 2°C / min to complete the sealing. Table 2 tests the air tightness, water resistance and thermal expansion coefficient of each embodiment. The air tightness of embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com