Aluminum alloy fluoride-free ammonium-free four-in-one sand surface pretreatment process

A treatment process and aluminum alloy technology, which is applied in the field of aluminum alloy fluorine-free and ammonium-free four-in-one sand treatment process, which can solve the problems of insufficient sanding capacity, many slots, improper selection of sodium dodecylsulfonate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5- 4

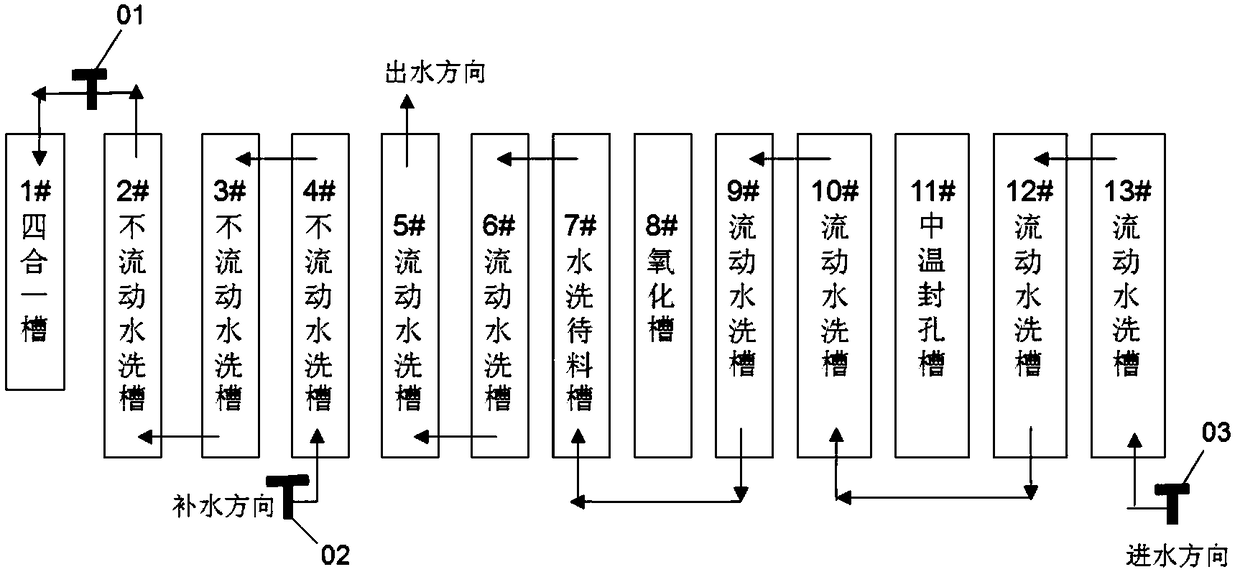

[0258] Example 5 - production of four-in-one sand surface material

[0259] The medicine formula and working index of each tank are:

[0260] 1# Four-in-one sand tank: sodium hydroxide 40g / L, sodium chloride 100 g / L, sodium thiosulfate 2.5g / L, sodium tripolyphosphate 2.5g / L, sorbitol 2.5g / L, glucose Sodium acid 2.5g / L, balance water; working temperature is 80°C, processing time is 10 minutes, trickling for 1 minute;

[0261] 2# Non-flowing water washing tank: water washing for 2 minutes, dripping for 30 seconds;

[0262] 3# Non-flowing water washing tank: water washing for 1.5 minutes, dripping for 30 seconds;

[0263] 4# Non-flowing water washing tank: water washing for 1 minute, dripping for 30 seconds;

[0264] 5# Flowing water washing tank: washing for 1 minute, dripping for 30 seconds;

[0265] 6# Flowing washing tank: washing for 1 minute, dripping for 30 seconds;

[0266] 7# Flowing water washing waiting tank: water washing for 1 minute, dripping for 30 seconds;

...

Embodiment 6- 4

[0274] Example 6 - Production of four-in-one sand surface material

[0275] Except that the working temperature of the 1# four-in-one sand surface tank is 90°C, the formulations and working indexes of other tanks are consistent with the treatment in Example 5. From Example 5 and Example 6, it can be concluded that as the temperature of the bath liquid increases, the reaction speed is accelerated, and the concentration of the medicament can be appropriately reduced to shorten the reaction time.

Embodiment 7- 4

[0276] Example 7 - Production of four-in-one sand surface material

[0277] The medicine formula and working index of each tank are:

[0278] 1# Four-in-one sand surface tank: sodium hydroxide 40g / L, sodium chloride 100g / L, sodium thiosulfate 2.5g / L, sodium tripolyphosphate 2.5g / L, sorbitol 2.5g / L, gluconic acid Sodium 2.5g / L, balance water; working temperature is 85°C, processing time is 8 minutes, trickling for 1 minute;

[0279] 2# Non-flowing water washing tank: water washing for 2 minutes, dripping for 30 seconds;

[0280] 3# Non-flowing water washing tank: water washing for 1.5 minutes, dripping for 30 seconds;

[0281] 4# Non-flowing water washing tank: water washing for 1 minute, dripping for 30 seconds;

[0282] 5# Flowing water washing tank: washing for 1 minute, dripping for 30 seconds;

[0283] 6# Flowing washing tank: washing for 1 minute, dripping for 30 seconds;

[0284] 7# Flowing water washing waiting tank: water washing for 1 minute, dripping for 30 seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com