A kind of anode material for seawater aluminum-air battery and preparation method thereof

An anode material and air battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex production process of anode materials, low high-power discharge efficiency, high battery cost, etc., and increase the effective utilization of alloys , Improving current efficiency and inhibiting hydrogen evolution corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

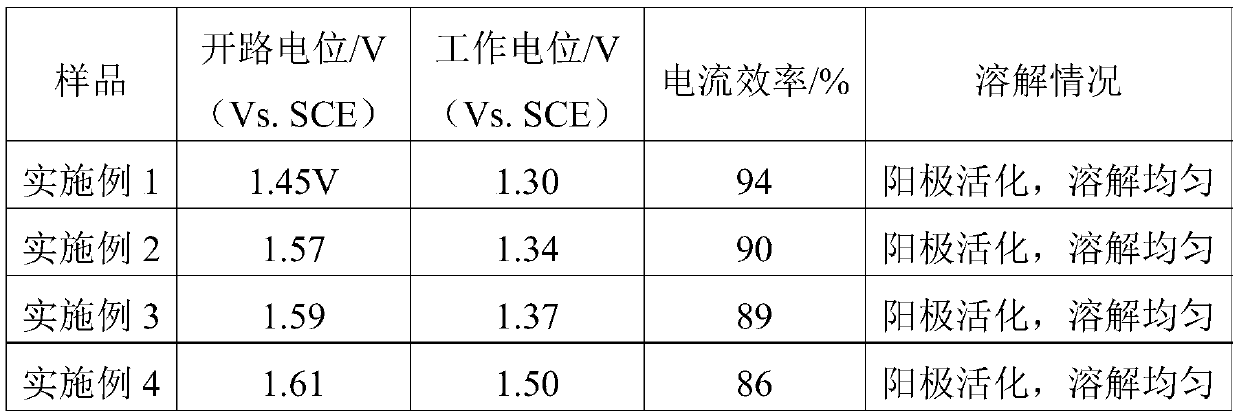

Examples

Embodiment 1

[0038] According to the composition and ingredients of sample A in Table 1, commercially pure aluminum (99.8wt% Al) was put into the melting furnace and melted (760°C) to form an aluminum alloy melt, and argon gas was introduced during the above process for protection. When the melt temperature is 730°C, use a graphite pressure cover to press the low melting point alloy elements Sn (99.9%), Ga (99.99%), Mg (99.85%), Zn (99.8wt%) (wrapped in aluminum foil) into the melt for 3 minutes, The completely melted aluminum alloy melt was stirred by electromagnetic for 10 min. Then the melt is introduced into a static furnace at 740°C, and a mixed gas composed of argon and hexachloroethane powder (hexachloroethane 50g / m 3 ) for 5 minutes, then inject pure argon for 10 minutes, the pressure of argon is 0.1MPa, and then stand still for 15 minutes to remove the oxidation scum on the surface of the aluminum alloy melt with a graphite tool. Cast the melt in the static furnace at a casting t...

Embodiment 2

[0040] According to the composition and ingredients of sample B in Table 1, industrial pure aluminum (99.8wt% Al) was put into the melting furnace and melted (760°C) to form an aluminum alloy melt. When the melt temperature is 730°C, use a graphite pressure cover to press the low melting point alloy elements Sn (99.9%), Ga (99.99%), Mg (99.85%), Zn (99.8wt%) (wrapped in aluminum foil) into the melt for 3 minutes, The completely melted aluminum alloy melt was stirred by electromagnetic for 10 min. Then the melt is introduced into a static furnace at 740°C, and a mixed gas composed of argon and hexachloroethane powder (hexachloroethane 50g / m 3 ) for 5 minutes, then inject pure argon for 10 minutes, the pressure of argon is 0.1MPa, and then stand still for 15 minutes to remove the oxidation scum on the surface of the aluminum alloy melt with a graphite tool. Cast the melt in the standing furnace at a casting temperature of 730°C, a casting speed of 300mm / min, and a cooling water...

Embodiment 3

[0042] According to the composition and ingredients of sample C in Table 1, commercially pure aluminum (99.8wt% Al) was put into a melting furnace and melted (760°C) to form an aluminum alloy melt, and argon gas was introduced for protection during the above process. When the melt temperature is 730°C, use a graphite pressure cover to press the low melting point alloy elements Sn (99.9%), Ga (99.99%), Mg (99.85%), Zn (99.8wt%) (wrapped in aluminum foil) into the melt for 3 minutes, The completely melted aluminum alloy melt was stirred by electromagnetic for 10 min. Then the melt is introduced into a static furnace at 740°C, and a mixed gas composed of argon and hexachloroethane powder (hexachloroethane 50g / m 3 ) for 5 minutes, then inject pure argon for 10 minutes, the pressure of argon is 0.1MPa, and then stand still for 15 minutes to remove the oxidation scum on the surface of the aluminum alloy melt with a graphite tool. Cast the melt in the static furnace at a casting tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com