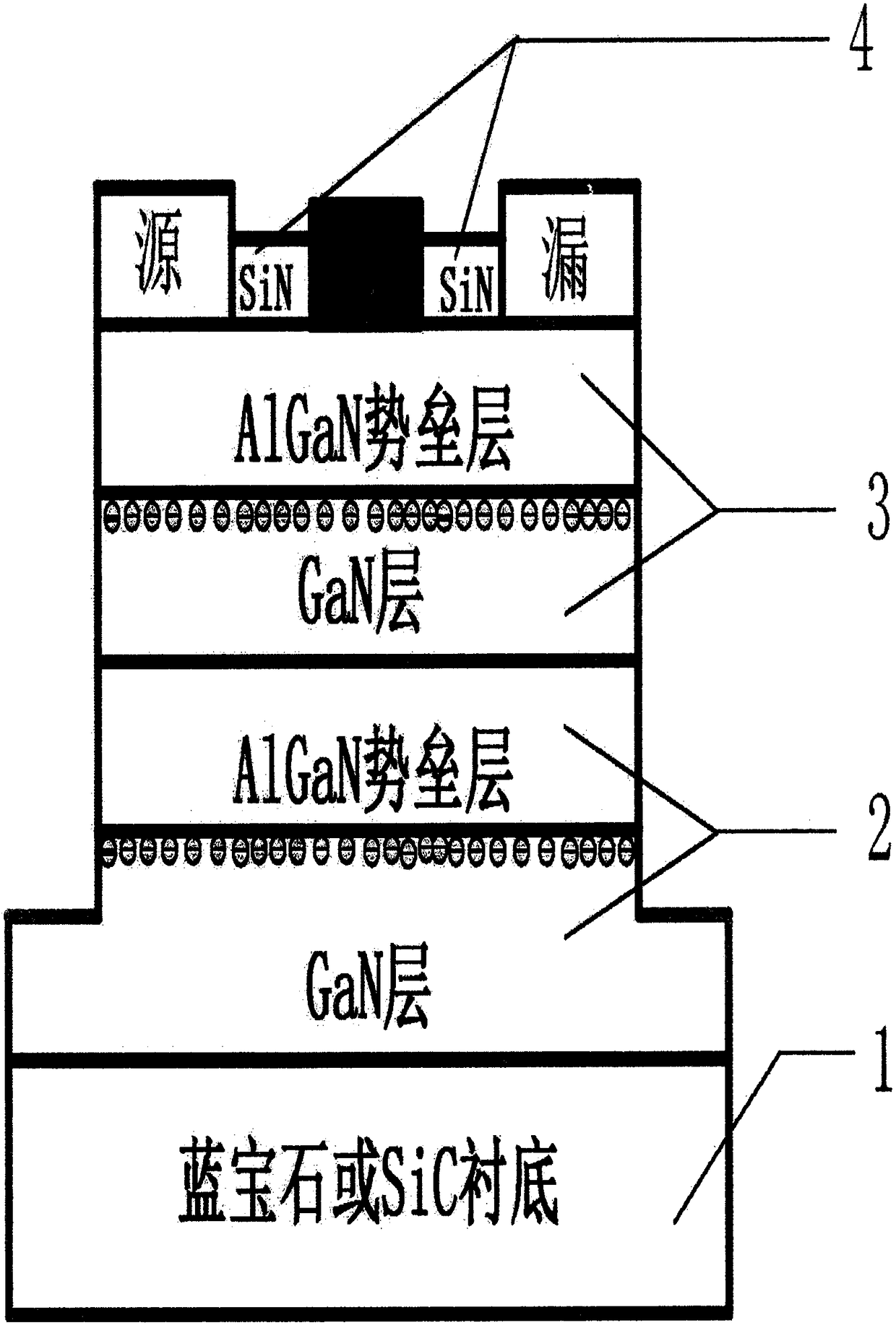

AlGaN/GaN high electron mobility transistor with multi-channel fin-type structure

A high electron mobility, fin structure technology, applied in the field of microelectronics, can solve the problems of low current driving capability and poor gate control capability of FinFET structure devices, and achieves improved device gain capability, enhanced gate control capability, and high current drive. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

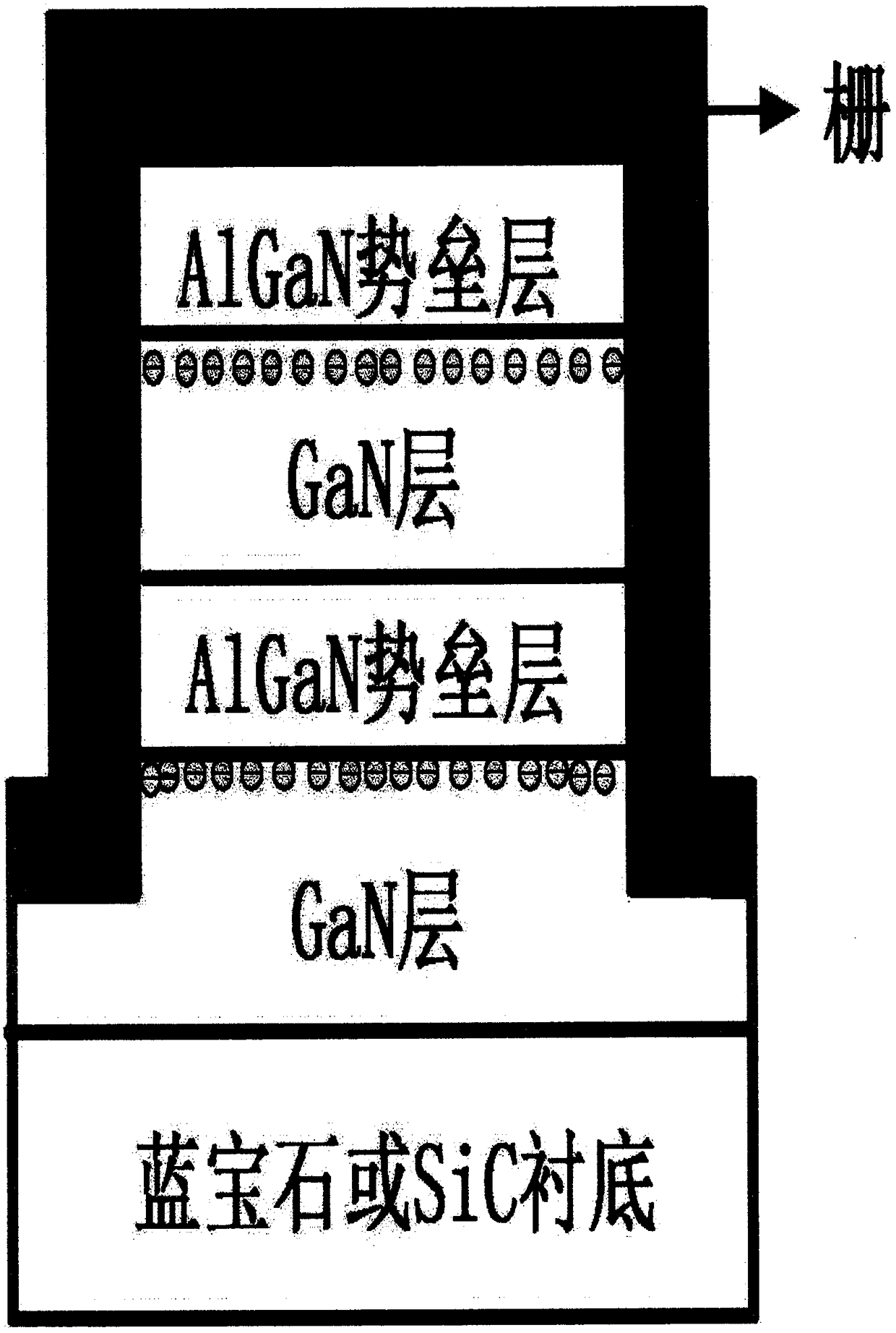

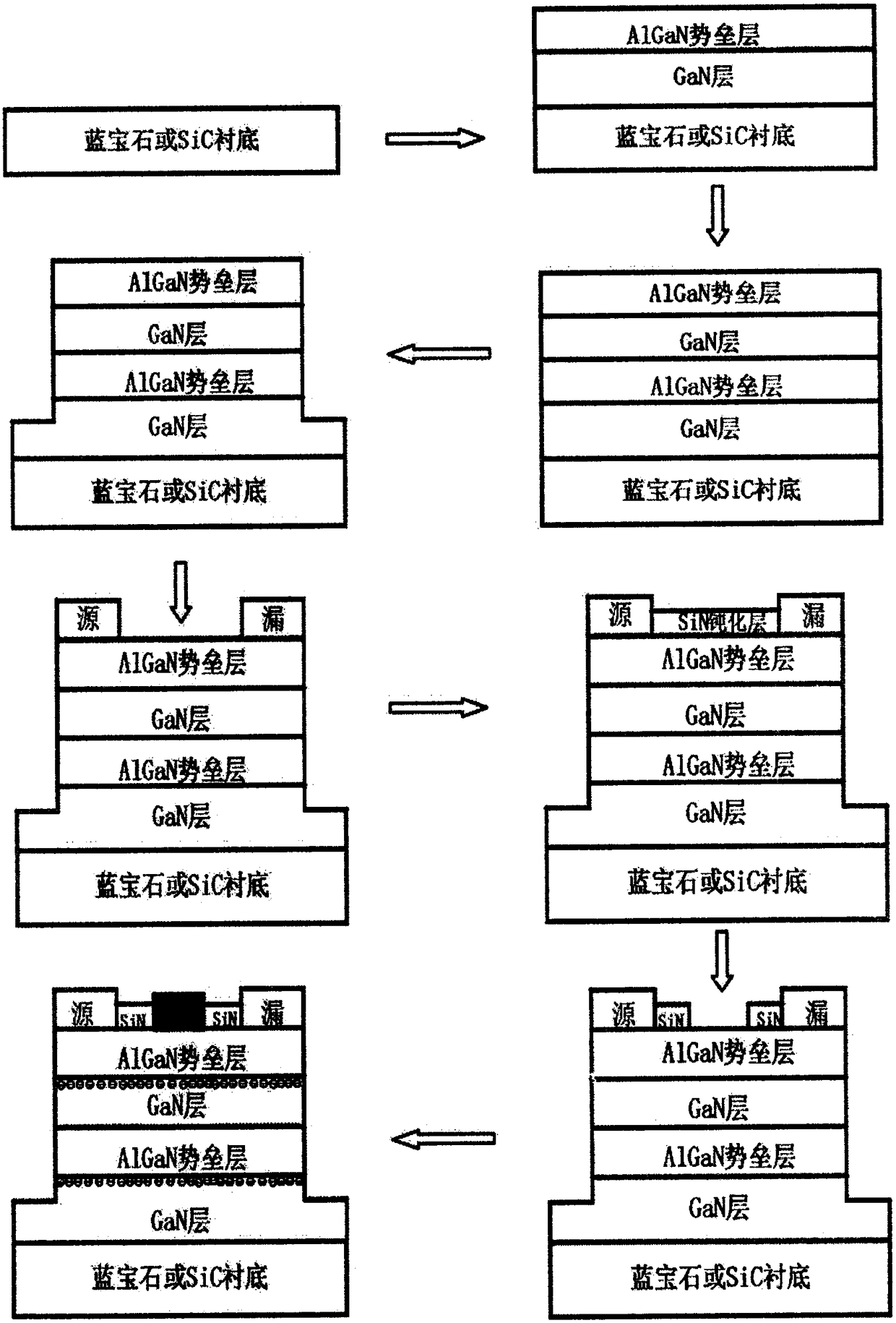

[0035] Embodiment 1: Fabricate a dual-channel fin-type AlGaN / GaN high electron mobility transistor with a gate fin width of 100 nm.

[0036] Step 1. Using the MOCVD process, epitaxially grow the double heterojunction.

[0037] 1.1) On the SiC substrate, grow an intrinsic GaN layer with a thickness of 1 μm;

[0038] 1.2) A 15nm-thick AlGaN barrier layer is grown on the intrinsic GaN layer, wherein the Al composition is 35%, and a two-dimensional electron gas is formed at the contact position between the intrinsic GaN layer and the AlGaN barrier layer, and the first layer of AlGaN / GaN heterojunction;

[0039] 1.3) regrowing a second intrinsic GaN layer with a thickness of 20 nm on the 15 nm thick AlGaN barrier layer;

[0040] 1.4) A second 15nm-thick AlGaN barrier layer is grown on the second intrinsic GaN layer, wherein the Al composition is 35%, to obtain a second layer of AlGaN / GaN heterojunction.

[0041] The process condition of this step is: with NH 3 is the N source,...

Embodiment 2

[0063] Embodiment 2: Manufacturing a three-channel fin-type AlGaN / GaN high electron mobility transistor with a gate fin width of 50 nm.

[0064] Step 1. Using the MOCVD process, epitaxially grow the triple heterojunction.

[0065] 1a) On a sapphire substrate, with NH 3 N source, MO source is Ga source, the growth temperature is 1000°C, and the intrinsic GaN layer with a thickness of 1.5 μm is grown;

[0066] 1b) On the intrinsic GaN layer, grow a 20nm-thick AlGaN barrier layer, in which the Al composition is 30%, and form a two-dimensional electron gas at the contact position between the intrinsic GaN layer and the AlGaN barrier layer, and obtain the first layer of AlGaN / GaN heterojunction;

[0067] 1c) growing a second intrinsic GaN layer with a thickness of 25 nm on the first AlGaN barrier layer with a thickness of 20 nm;

[0068] 1d) growing a second 20nm-thick AlGaN barrier layer on the second intrinsic GaN layer, wherein the Al composition is 30%, to obtain a second l...

Embodiment 3

[0091] Embodiment 3: Manufacturing a double-channel fin-type AlGaN / GaN high electron mobility transistor with a gate fin width of 30 nm.

[0092] Step A. Using the MOCVD process, epitaxially grow the double heterojunction.

[0093] in NH 3 is the N source, the MO source is the Ga source, and the growth temperature is 1000°C, first grow an intrinsic GaN layer with a thickness of 2 μm on the SiC substrate; then grow a 25nm thick GaN layer on the intrinsic GaN layer. The AlGaN barrier layer, in which the Al composition is 25%, forms a two-dimensional electron gas at the contact position between the intrinsic GaN layer and the AlGaN barrier layer, and obtains the first layer of AlGaN / GaN heterojunction; then the 25nm thick AlGaN barrier layer A second intrinsic GaN layer with a thickness of 30nm is grown on the barrier layer; finally, a second AlGaN barrier layer with a thickness of 25nm is grown on the second intrinsic GaN layer, wherein the Al composition is 25%, and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com