Chemical solvent-resistant conduction type PC/ABS composite material

A composite, conductive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

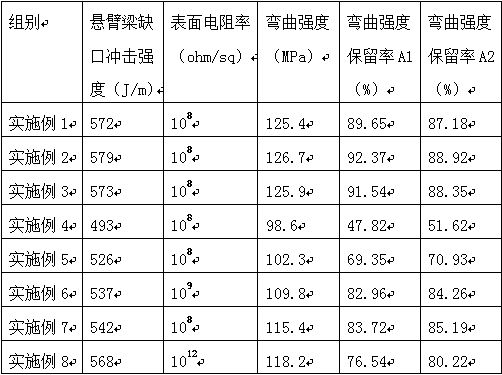

Examples

Embodiment 1

[0021] A conductive PC / ABS composite material resistant to chemical solvents, comprising the following raw materials in parts by weight: 62 parts of PC resin, 31 parts of ABS resin, 18 parts of modified o-cresol novolac epoxy resin, 2.9 parts of barium titanate ceramic powder, 1.2 parts of imide salt, 0.7 part of antioxidant, 0.2 part of initiator, 0.2 part of zinc stearate;

[0022] The melting temperature of the PC resin is 225°C, and the melt flow rate is 40g / 10min;

[0023] The ABS resin is an acrylonitrile-butadiene-styrene copolymer, and its relative molecular weight is 160000-200000g / mol; wherein the weight percentage of acrylonitrile monomer is 38%, and the weight ratio of butadiene monomer is 18% , the balance is styrene monomer;

[0024] The preparation method of modified o-cresol novolac epoxy resin is as follows: in parts by weight, take 70 parts of o-cresol novolac epoxy resin with a mass ratio content of easily saponifiable chlorine lower than 100 μg / g, 5 parts ...

Embodiment 2

[0034] A conductive PC / ABS composite material resistant to chemical solvents, comprising the following raw materials in parts by weight: 60 parts of PC resin, 34 parts of ABS resin, 16 parts of modified o-cresol novolac epoxy resin, 2.6 parts of barium titanate ceramic powder, 0.8 part of imide salt, 0.6 part of antioxidant, 0.3 part of initiator, 0.1 part of zinc stearate;

[0035] The melting temperature of the PC resin is 220°C, and the melt flow rate is 50g / 10min;

[0036] The ABS resin is an acrylonitrile-butadiene-styrene copolymer, and its relative molecular weight is 160000-200000g / mol; wherein the weight percentage of acrylonitrile monomer is 36%, and the weight ratio of butadiene monomer is 20% , the balance is styrene monomer;

[0037]The preparation method of modified o-cresol novolac epoxy resin is as follows: in parts by weight, take 75 parts of o-cresol novolac epoxy resin with a mass ratio content of easily saponifiable chlorine lower than 100 μg / g, 4 parts of...

Embodiment 3

[0047] A conductive PC / ABS composite material resistant to chemical solvents, comprising the following raw materials in parts by weight: 65 parts of PC resin, 28 parts of ABS resin, 20 parts of modified o-cresol novolac epoxy resin, 3.2 parts of barium titanate ceramic powder, 1.6 parts of imide salt, 0.8 part of antioxidant, 0.1 part of initiator, 0.3 part of zinc stearate;

[0048] The melting temperature of the PC resin is 230°C, and the melt flow rate is 30g / 10min;

[0049] The ABS resin is an acrylonitrile-butadiene-styrene copolymer, and its relative molecular weight is 160000-200000g / mol; wherein the weight percentage of acrylonitrile monomer is 40%, and the weight ratio of butadiene monomer is 15% , the balance is styrene monomer;

[0050] The preparation method of the modified o-cresol novolac epoxy resin is as follows: in parts by weight, take 65 parts of o-cresol novolac epoxy resin, 6 parts of C5 petroleum resin, and 1 6 parts, 6 parts of diisocyanate, after heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com