A hydrophobic sio 2 Coated halogen-free intumescent flame retardant and its preparation method and application

An intumescent flame retardant and hydrophobic modifier technology, applied in the field of flame retardants, can solve the problems of increasing the difficulty of waste liquid separation and treatment, and achieve the effects of avoiding dissolution loss, strong operability, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Add 5mL of cationic polyelectrolyte polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 2% and 95mL of absolute ethanol into the three-necked bottle and stir evenly, then disperse 15g of the halogen-free expansion flame retardant ammonium polyphosphate Pretreatment was performed in the above solution, and after stirring at room temperature for 6 minutes, solid-liquid separation was carried out to obtain a halogen-free intumescent flame retardant ammonium polyphosphate with positive charges on the surface.

[0038] 2) Add 100mL absolute ethanol, 2.0mL ultrapure water, 3.0mL NH 3 ·H 2 O, after stirring for 2min, directly add 3.0mL orthosilicate ethyl ester, and after magnetic stirring reaction for 4.0h, the nano-SiO with negative charge on the surface is obtained. 2 Collagen solution.

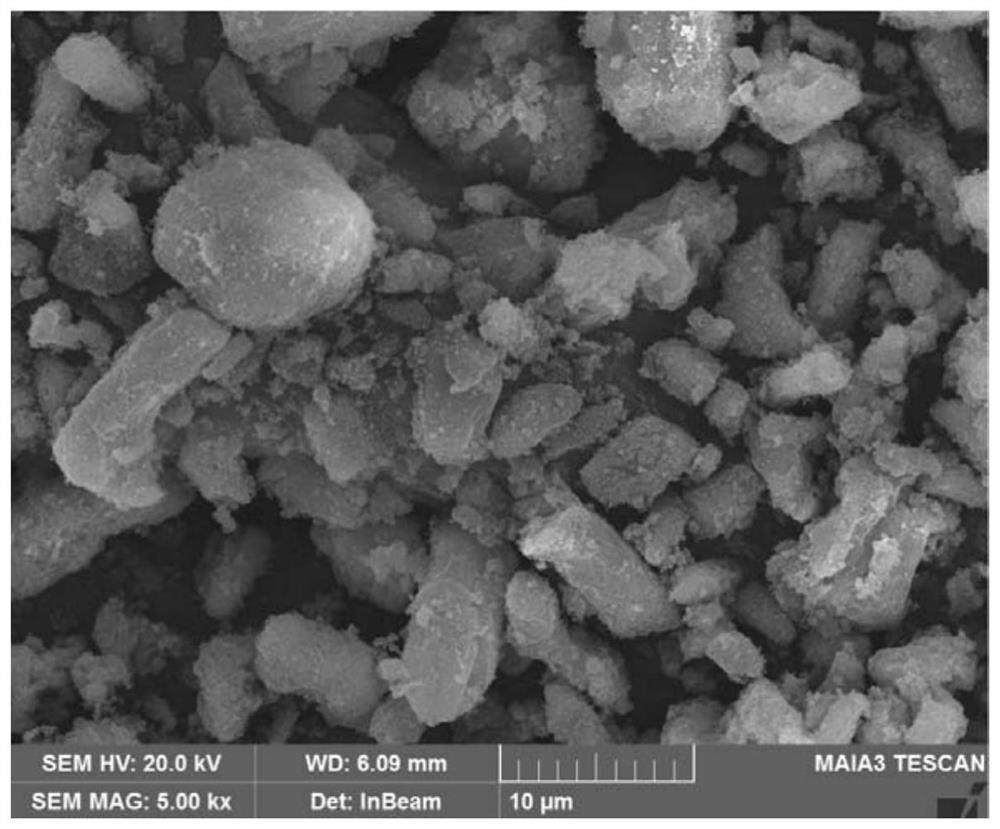

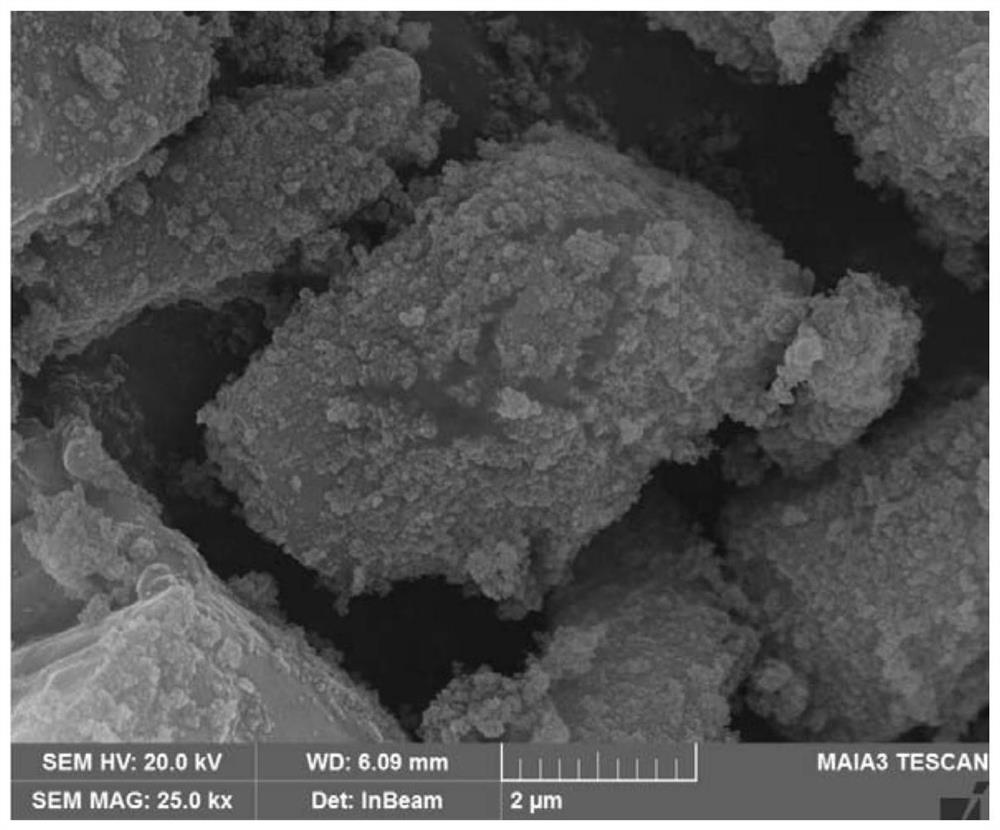

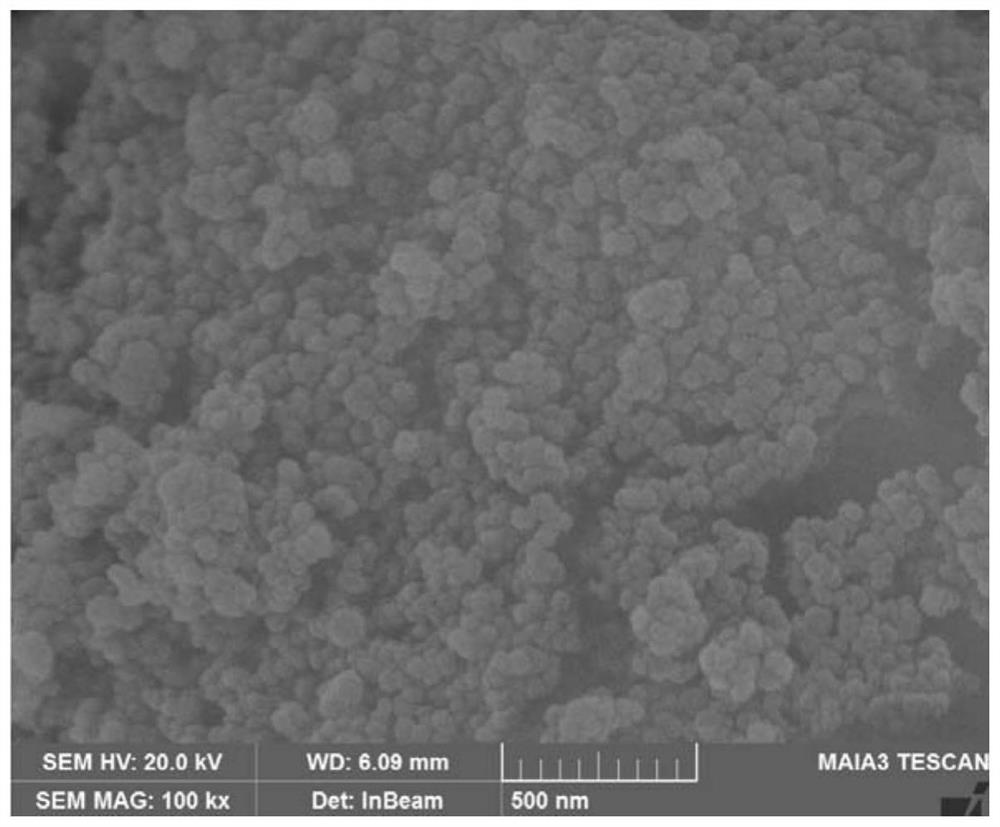

[0039] 3) The positively charged halogen-free intumescent flame retardant prepared in step 1) is directly added to the negatively charged nano-SiO in st...

Embodiment 2

[0042] 1) Add 3mL of cationic polyelectrolyte polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 4% and 97mL of absolute ethanol into the there-necked bottle and stir evenly, then disperse 20g of halogen-free intumescent flame retardant melamine in the above-mentioned Pretreatment is carried out in the solution, and after stirring at room temperature for 8 minutes, solid-liquid separation is carried out to obtain the positively charged halogen-free intumescent flame retardant melamine on the surface.

[0043] 2) Add 100mL absolute ethanol, 2.8mL ultrapure water, 4.0mL NH 3 ·H 2 O, after stirring for 4min, directly add 4.5mL orthosilicate ethyl ester, and after magnetic stirring for 5.5h, the nano-SiO with negative charge on the surface is obtained. 2 Collagen solution.

[0044] 3) The positively charged halogen-free intumescent flame retardant melamine prepared in step 1) is directly added to the negatively charged nano-SiO in step 2). 2 Coll...

Embodiment 3

[0047] 1) Add 2.5mL of cationic polyelectrolyte polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 6% and 97.5mL of absolute ethanol into the there-necked bottle and stir evenly, then mix the halogen-free expansion flame retardant melamine phosphate 25 g was dispersed in the above solution for pretreatment, and after stirring at room temperature for 10 minutes, solid-liquid separation was carried out to obtain a halogen-free intumescent flame retardant melamine phosphate with a positive charge on the surface.

[0048] 2) Add 100mL absolute ethanol, 1.0mL ultrapure water, 5.0mL NH 3 ·H 2 O, after stirring for 5min, directly add 5.5mL orthosilicate ethyl ester, and after magnetic stirring for 7.5h, the nano-SiO with negative charge on the surface is obtained. 2 Collagen solution.

[0049] 3) Add the positively charged halogen-free intumescent flame retardant melamine phosphate prepared in step 1) directly to the negatively charged nano-SiO in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com