Crystallization modifier capable of improving properties of chemical drug raw material powder and preparation method for crystallization modifier

The technology of raw material powder and modified substance is applied in the field of crystalline modification for improving the chemical properties of chemical raw material powder and its preparation, which can solve the problems of high cost, large consumption of organic solvent, hidden dangers in drug use safety, and the like. Outline reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

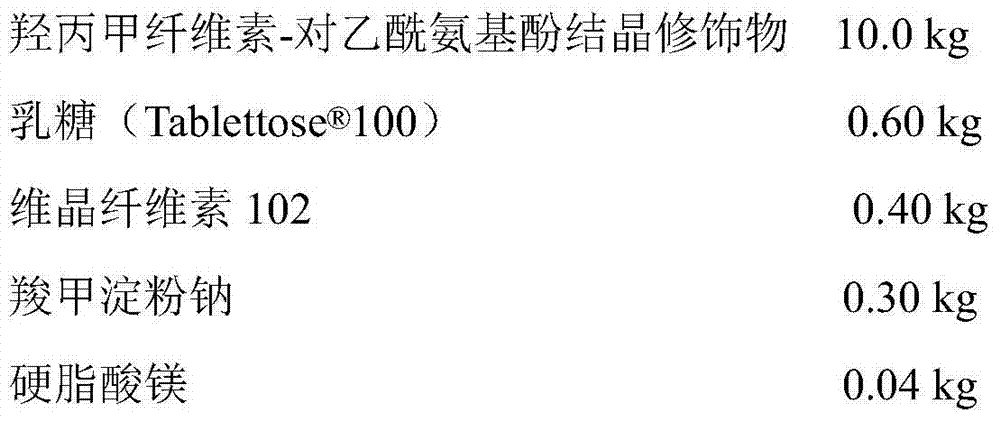

[0034] Example 1: Hypromellose-paracetamol crystalline modification tablet compression process (API: 87.30%)

[0035] Paracetamol (100 mesh) 10.10kg

[0036] Modifier A-1 2.10kg

[0037] Preparation Process:

[0038] 1. Modifier preparation

[0039] Take 0.10 kg of hypromellose (3-10 mPa·s) and dissolve it in 2.40 kg of water under stirring to obtain modifier A-1.

[0040] 2. Preparation of modifiers

[0041] (1) Take acetaminophen (needle crystal) and pulverize it, pass through a 100-mesh sieve to obtain I.

[0042] (2) Put I in a high-speed mixing granulator, stir at a low speed, slowly add modifier A-1, cut and granulate at a low speed, mix until the cutting current is 4.0A, and obtain II.

[0043] (3) Put II in the fluidized granulator, control the inlet air temperature to 70°C, the humidity to 45% to 65%, and the moisture to 1.5% to 2.5%. The obtained intermediate product was passed through a 30-mesh sieve to obtain 10.15 kg of hypromellose-paracetamol crystalline mod...

Embodiment 2

[0076] Example 2: Hypromellose-sulpiride crystalline modification tablet compression process (API: 77.93%)

[0077] Sulpiride (100 mesh) 10.20kg

[0078] Modifier A-2 2.40kg

[0079] Preparation Process:

[0080] 1. Modifier preparation

[0081] Take 0.05 kg of hypromellose (3-10 mPa·s) and dissolve it in 2.45 kg of alcohol-containing water (weight percentage: ethanol: water = 50:50) under stirring to obtain modifier A-2.

[0082] 2. Preparation of modifiers

[0083] ⑴ Take the raw material of sulpiride, pulverize it, and pass through a 100-mesh sieve to obtain I.

[0084] (2) Put I in a high-speed mixing granulator, stir at a low speed, slowly add modifier A-2, cut and granulate at a low speed, mix until the cutting current is 3.6A, and obtain II.

[0085] (3) Put II in the fluidized granulator, control the inlet air temperature to 70°C, the humidity to 45%-65%, and the moisture content to be 1.0%-2.0%. The obtained intermediate product was passed through a 30-mesh siev...

Embodiment 3

[0095] Example 3: Hypromellose-amlodipine besylate crystal modification tablet compression process (API: 3.93%)

[0096] Amlodipine besylate (100 mesh) 10.10kg

[0097] Modifier A-3 2.20kg

[0098] Preparation Process:

[0099] 1. Modifier preparation

[0100]Take 0.10 kg of hypromellose (3-10 mPa·s) and dissolve it in 2.40 kg of alcohol-containing water (weight percentage: ethanol: water = 30:70) under stirring to obtain modifier A-3.

[0101] 2. Preparation of modifiers

[0102] (1) Take amlodipine besylate raw material and pulverize it, pass through a 100-mesh sieve to obtain I.

[0103] (2) Put Ⅰ in a high-speed mixing granulator, turn on low-speed stirring, slowly add modifier A-3 into the granulator, turn on low-speed cutting and granulating, mix until the cutting current is 3.8A, and get Ⅱ.

[0104] (3) Put II in the fluidized granulator, control the inlet air temperature at 70°C, humidity at 45% to 65%, dry, and control the moisture at 2.0% to 2.5%. The obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com