Rare earth-doped cyano-based material, preparation method and application, and sodium-ion battery

A sodium-ion battery, rare earth doping technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lower battery energy density, poor material processing performance, and unstable structure, and achieve improved conductivity and low cost , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In a second aspect, in at least one embodiment, a method for preparing the above-mentioned rare earth-doped cyano-based material is provided, comprising the following steps:

[0065] (a) Sodium ferrocyanide, sodium salt and water are mixed to obtain solution A;

[0066] (b) soluble divalent manganese salt is mixed with water to obtain solution B;

[0067] (c) mixing a soluble salt containing a rare earth type doping element M with water to obtain a solution C;

[0068] (d) Add solution B and solution C gradually to solution A at the same time, and obtain rare earth-doped cyano-based materials after co-precipitation reaction.

[0069] The preparation method of the present invention can not only improve the lattice stability, corrosion resistance, electrical conductivity and density of the cyano-based material, thereby significantly promoting the improvement of the cycle stability and rate performance of the material, and prolonging the service life of the material. Mor...

Embodiment 1

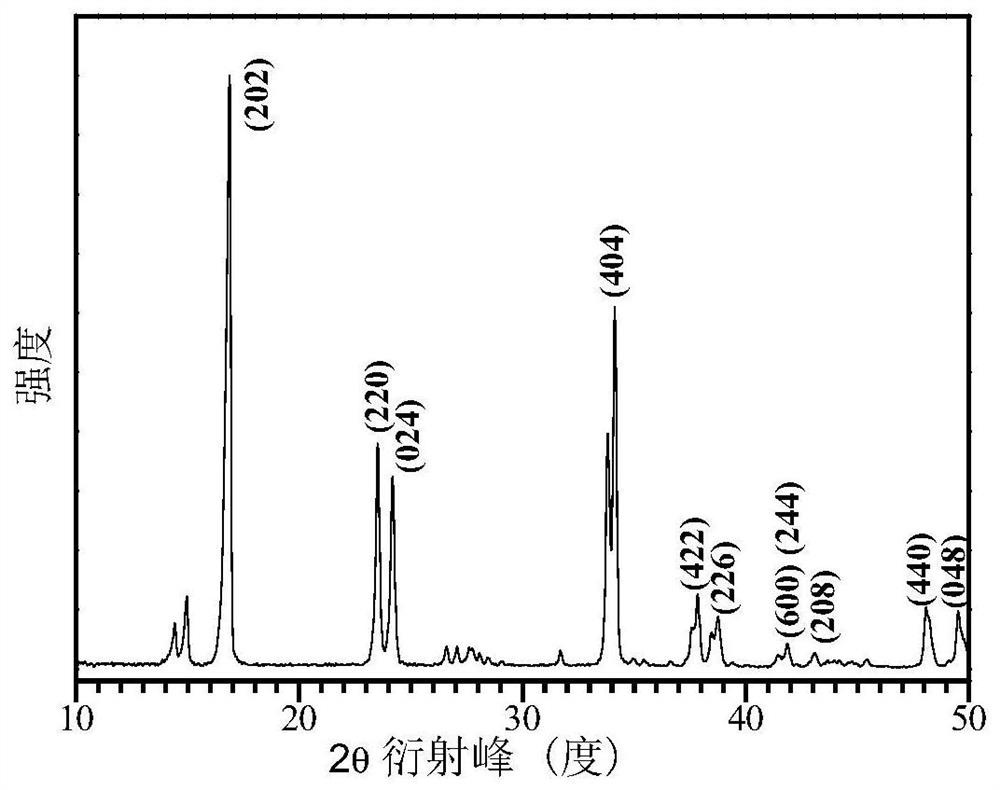

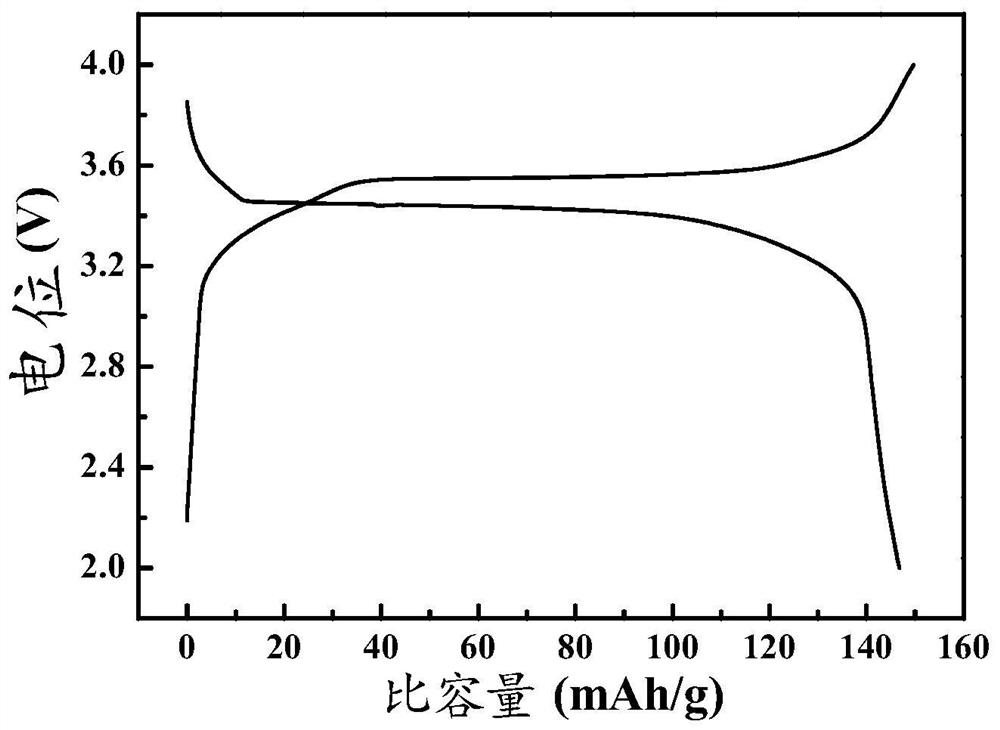

[0098] A rare earth doped cyano-based material, the chemical formula of the cyano-based material is Na x mn 1-y La y [Fe(CN) 6 ], where, 0<x≤2, 0<y≤0.2; the cyano-based material has a rhombohedral crystal structure.

[0099] The preparation method of the doped cyano-based material comprises the following steps:

[0100] Dissolve sodium ferrocyanide and sodium chloride in deionized water, and stir evenly to obtain solution A. The concentration of ferrocyanide ions in the solution is 0.1mol / L, and the molar weight of sodium chloride is 80% of that of sodium ferrocyanide. times;

[0101] Dissolve manganese sulfate in deionized water to obtain Mn 2+ Solution B with a concentration of 0.2mol / L, the volume ratio of solution B to solution A is 1:1;

[0102] Dissolve lanthanum sulfate in deionized water to obtain 3+ Solution C with a concentration of 0.015mol / L, the volume ratio of solution C to solution B is 1:1;

[0103] Then, under constant stirring, add solution C and solu...

Embodiment 2

[0122] A rare earth doped cyano-based material, the chemical formula of the cyano-based material is Na x mn 1-y Ce y [Fe(CN) 6 ], where, 0<x≤2, 0<y≤0.2; the cyano-based material has a rhombohedral crystal structure.

[0123] The preparation method of the doped cyano-based material comprises the following steps:

[0124] Dissolve sodium ferrocyanide and sodium chloride in deionized water, stir well to obtain solution A, the concentration of ferrocyanide ions in the solution is 0.2mol / L, and the molar weight of sodium chloride is 90% of that of sodium ferrocyanide. times;

[0125] Dissolve manganous chloride in deionized water to obtain 2+ Solution B with a concentration of 0.4mol / L, the volume ratio of solution B to solution A is 1:1;

[0126] Dissolve cerium chloride in deionized water to obtain Ce 3+ Solution C with a concentration of 0.05mol / L, the volume ratio of solution C to solution B is 1:1;

[0127] Then, under constant stirring, add solution C and solution B t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com