A kind of synthetic method of 2,4,6-tribromophenyl allyl ether

A technology of tribromophenyl allyl ether and synthesis method, applied in chemical instruments and methods, ether preparation, ether preparation by ester reaction, etc., can solve the problem of slow etherification reaction process, serious hydrolysis of chloropropene, affecting market application, etc. problems, to avoid the formation of by-products, to avoid hydrolysis, and to facilitate large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of synthesis of 2,4,6-tribromophenyl allyl ether, it comprises the following steps successively:

[0026] 1) Synthesis of the ethanol solution of tribromophenol sodium salt:

[0027] Add 94g of phenol, 470g of organic solvent dichloromethane into the four-necked flask, add 0.47g of catalyst I iron powder, and when the reaction temperature is controlled at 15°C, add 346.2g of brominating agent bromine chloride (control the reaction temperature not to exceed 20°C ), heat up to 25°C and then keep the temperature for 4 hours, then remove the catalyst I by filtration, recycle the organic solvent by distillation, and the remaining product is tribromophenol; g After the reaction is complete, the ethanol solution of tribromophenol sodium salt is obtained.

[0028] 2) Synthesis of 2,4,6-tribromophenyl allyl ether:

[0029] Add 0.94 g of dispersant p-octylphenol polyoxyethylene ether and 1.88 g of catalyst II tetramethylammonium chloride to the ethanol solution of tribro...

Embodiment 2

[0031] A kind of synthetic method of 2,4,6-tribromophenyl allyl ether, it comprises the following steps successively:

[0032] 1) Synthesis of the ethanol solution of tribromophenol sodium salt:

[0033] Add 94g of phenol, 940g of ethylene dichloride as the organic solvent, 4.7g of catalyst I tin powder, and control the reaction temperature at 20°C (control the reaction temperature not to exceed 20°C) and add the brominating agent bromine chloride to the four-neck flask After 357.7g, heat up to 30°C and keep warm for 5h, then filter to remove catalyst Ⅰ, distill and recover organic solvent, and the remaining product is tribromophenol; g After the reaction is complete, the ethanol solution of tribromophenol sodium salt is obtained.

[0034] 2) Synthesis of 2,4,6-tribromophenyl allyl ether:

[0035] In the ethanolic solution of tribromophenol sodium salt that step 1) makes, add dispersant sodium dodecylsulfonate 4.7g and catalyzer II tetraethylammonium bromide 9.4g, first be w...

Embodiment 3

[0037] A kind of synthetic method of 2,4,6-tribromophenyl allyl ether, it comprises the following steps successively:

[0038] 1) Synthesis of the ethanol solution of tribromophenol sodium salt:

[0039] Add 94g of phenol, 705g of chloroform as the organic solvent, 2.4g of antimony powder as the catalyst I, and control the reaction temperature at 16°C (control the reaction temperature not to exceed 20°C), add brominating agent to chlorinate After 346.2g of bromine, heat up to 26°C and keep it warm for 5 hours, then filter to remove catalyst Ⅰ, distill and recover the organic solvent, and the remaining product is tribromophenol; then add tribromophenol to the ethanol solution with a mass concentration of 15% sodium ethoxide After 527.4 g of the reaction was completed, an ethanol solution of tribromophenol sodium salt was obtained.

[0040] 2) Synthesis of 2,4,6-tribromophenyl allyl ether:

[0041] Add 2.1 g of dispersing agent sodium dodecylbenzenesulfonate and 3.2 g of catal...

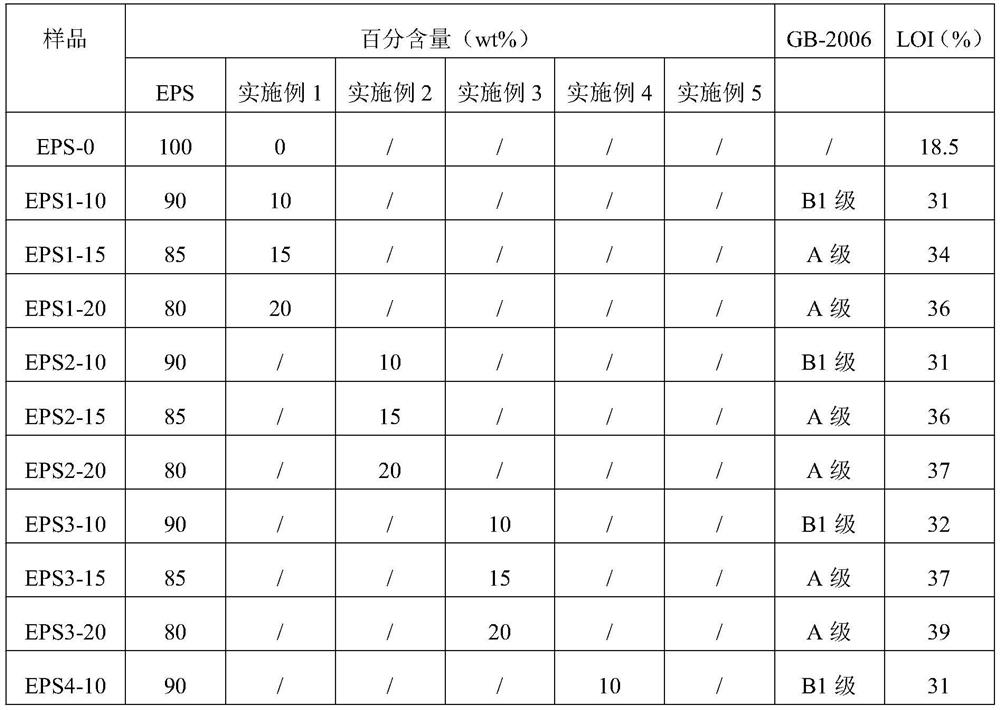

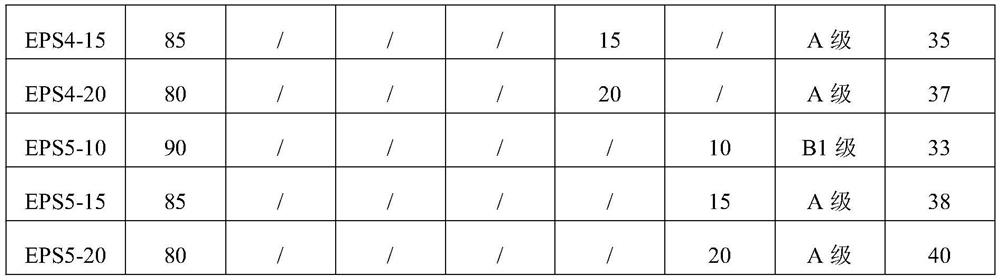

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com