Preparation method for 2XXX aluminum and aluminum alloy surface high-wear-resistance self-lubricating micro-arc oxide film layer

A technology of aluminum alloy surface, micro-arc oxidation, applied in surface reaction electrolytic coating, anodizing, coating and other directions, can solve problems such as high cost, complexity, lubrication failure, etc., achieve uniform thickness, reduce instantaneous current impact, combine good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

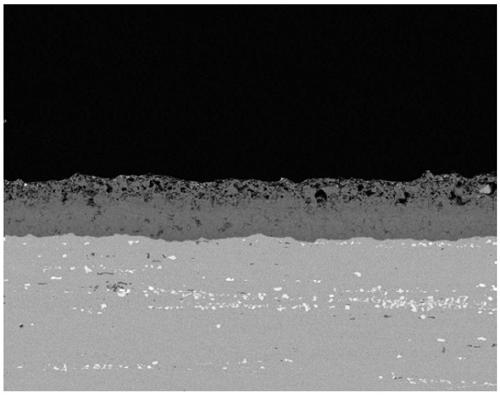

Image

Examples

Embodiment 1

[0033] 1. Material preparation: After the 2A12 aluminum alloy is cut and polished, it is cleaned and degreased by ultrasonic waves in acetone solution.

[0034] 2. DC copper-rich passivation: In the passivation electrolyte, water glass 20g / L, sodium adipate 5g / L, stabilizer 2g / L, and the rest is water. The temperature is 20-45°C, and it is treated for 10 minutes. After taking it out, it is immediately washed with tap water for 1-2 minutes, and then with deionized water for 1-2 minutes. The thickness of the obtained copper-rich dense passivation film is 2 µm.

[0035] 3. AC α-Al 2 o 3Sintering of self-lubricating dense film layer: In the electrolyte, sodium gluconate 20g / L, sodium silicate 2g / L, molybdenum disulfide 10g / L, sodium borate 5g / L, combustion agent 2g / L, and the rest is water.

[0036] The first stage: oxidation time: 60min, forward voltage: 400V, forward current density: 2A / cm 2 , negative voltage: 60V, negative current density: 3A / cm 2 , Pulse frequency: 400Hz;...

Embodiment 2

[0041] 1. Material preparation: After the 2A16 aluminum alloy is cut and polished, it is cleaned and degreased by ultrasonic in acetone solution.

[0042] 2. DC copper-rich passivation: In the passivation electrolyte, water glass 30g / L, sodium adipate 8g / L, stabilizer 2g / L, and the rest is water. The temperature is 20-45°C, and it is treated for 20 minutes. After taking it out, it is immediately washed with tap water for 1-2 minutes, and then with deionized water for 1-2 minutes. The thickness of the obtained copper-rich dense passivation film is 5 µm.

[0043] 3. AC α-Al 2 o 3 Sintering of self-lubricating dense film layer: In the electrolyte, sodium gluconate 20g / L, sodium silicate 3g / L, molybdenum disulfide 20g / L, sodium borate 2g / L, combustion agent 5g / L, and the rest is water.

[0044] The first stage: oxidation time: 80min, forward voltage: 450V, forward current density: 3A / cm 2 , negative voltage: 80V, negative current density: 3A / cm 2 , Pulse frequency: 400Hz; posi...

Embodiment 3

[0049] 1. Material preparation: After the 2A70 aluminum alloy is cut and polished, it is cleaned and degreased by ultrasonic in acetone solution.

[0050] 2. DC copper-rich passivation: In the passivation electrolyte, water glass 15g / L, sodium adipate 8g / L, stabilizer 3g / L, and the rest is water. The temperature is 20-45°C, and it is treated for 20 minutes. After taking it out, it is immediately washed with tap water for 1-2 minutes, and then with deionized water for 1-2 minutes. The thickness of the obtained copper-rich dense passivation film is 5 µm.

[0051] 3. AC α-Al 2 o 3 Sintering of self-lubricating dense film layer: In the electrolyte, sodium gluconate 30g / L, sodium silicate 3g / L, molybdenum disulfide 15g / L, sodium borate 2g / L, combustion agent 5g / L, and the rest is water.

[0052] The first stage: oxidation time: 80min, forward voltage: 450V, forward current density: 2A / cm 2 , negative voltage: 80V, negative current density: 5A / cm 2 , Pulse frequency: 200Hz; posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com