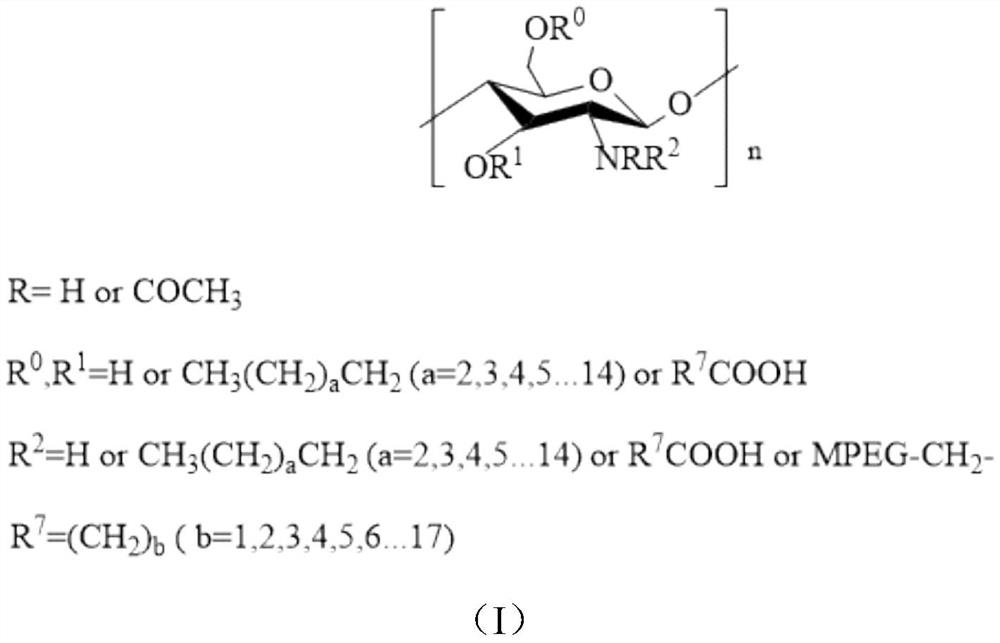

A kind of polyether grafted oil-in-water type crude oil demulsifier and preparation method thereof

A crude oil demulsifier and oil-in-water type technology, which is applied in chemical dehydration/demulsification, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of secondary pollution, poor environmental friendliness of demulsifier, etc., and achieve a clean oil-water interface , strong competitive adsorption capacity, good effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

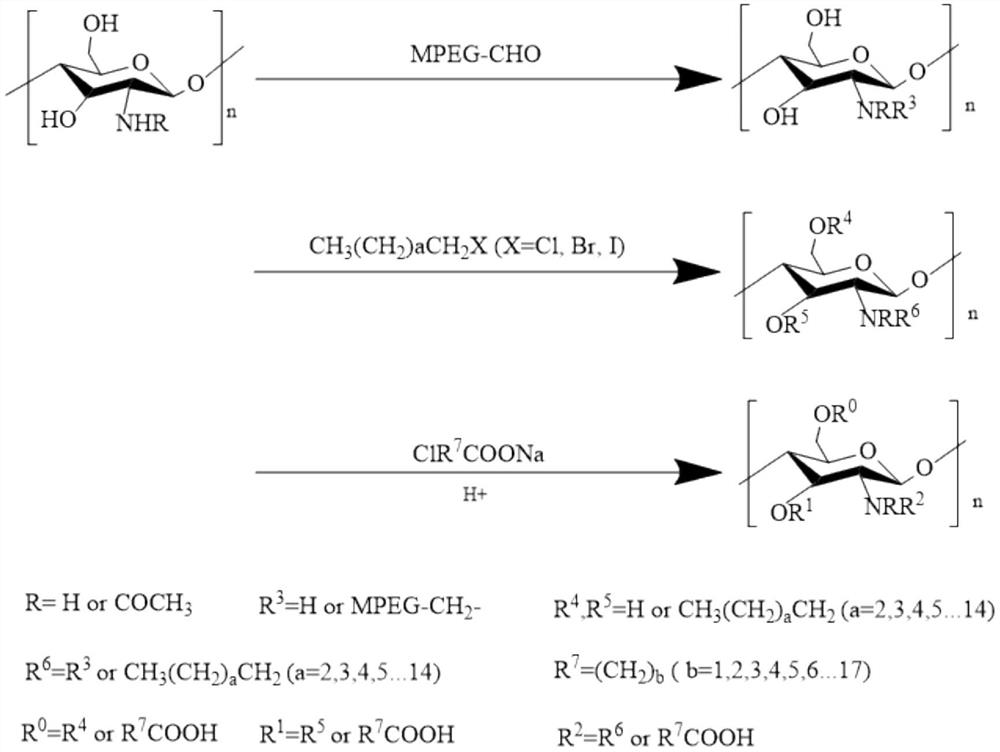

Method used

Image

Examples

Embodiment 1

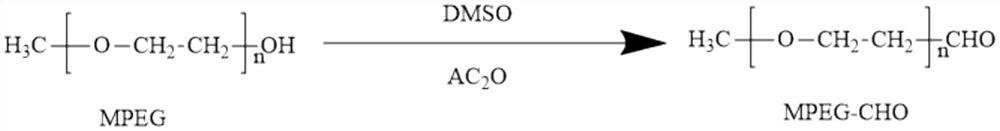

[0042] The preparation of the butyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0043] (1) Synthesis of formylated polyethylene glycol monomethyl ether: get polyethylene glycol monomethyl ether (M n =5000) 5g (1mmol) dissolved in 2mL chloroform, keep the reaction in a nitrogen environment, add 1.1mL (10mmol) acetic anhydride and 30mL anhydrous dimethyl sulfoxide at room temperature under constant stirring, raise the temperature to 35°C, and react at constant temperature for 15h . After the reaction was completed, the reaction solution was added to 400 mL of anhydrous ether, and the obtained precipitate was dissolved in chloroform and then recrystallized with ether solution (repeat this step once), and then vacuum-dried at room temperature for 24 h to obtain the formylated polyethylene glycol mono methyl ether.

[0044] (2) Synthesis of chitosan grafted with polyethylene glycol monomethyl ether: accurately weigh 1...

Embodiment 2

[0048] The preparation of the hexyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0049] (1) Synthesis of formylated polyethylene glycol monomethyl ether: get polyethylene glycol monomethyl ether (M n =1900) 1.9g (1mmol) dissolved in 2mL chloroform, keep the reaction in a nitrogen atmosphere, add 1.1mL (10mmol) acetic anhydride and 30mL anhydrous dimethyl sulfoxide at room temperature under constant stirring, raise the temperature to 35°C, and react at a constant temperature 15h. After the reaction was completed, the reaction solution was added to 400 mL of anhydrous ether, and the obtained precipitate was dissolved in chloroform and then recrystallized with ether solution (repeat this step once), and then vacuum-dried at room temperature for 24 h to obtain the formylated polyethylene glycol mono methyl ether;

[0050] (2) Synthesis of chitosan grafted with polyethylene glycol monomethyl ether: accurately weigh 1.0...

Embodiment 3

[0054] The preparation of the octyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0055] (1) Synthesis of formylated polyethylene glycol monomethyl ether: get polyethylene glycol monomethyl ether (M n =750) 0.75g (1mmol) dissolved in 2mL chloroform, keep the reaction in a nitrogen environment, add 1.1mL (10mmol) acetic anhydride and 30mL anhydrous dimethyl sulfoxide under constant stirring at room temperature, raise the temperature to 35°C, and react at a constant temperature 15h. After the reaction was completed, the reaction solution was added to 400 mL of anhydrous ether, and the obtained precipitate was dissolved in chloroform and then recrystallized with ether solution (repeat this step once), and then vacuum-dried at room temperature for 24 h to obtain the formylated polyethylene glycol mono methyl ether;

[0056] (2) Synthesis of octylcarboxymethyl chitosan grafted with polyethylene glycol monomethyl ether: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com