PET (Polyethylene Terephthalate) protection film and preparation method thereof

A protective film and protective layer technology, applied in the direction of film/sheet adhesive, adhesive type, adhesive, etc., can solve the problems of difficult industrial production, large investment in equipment cost, and many composite layers, etc., to achieve Long service life, improved overall performance, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

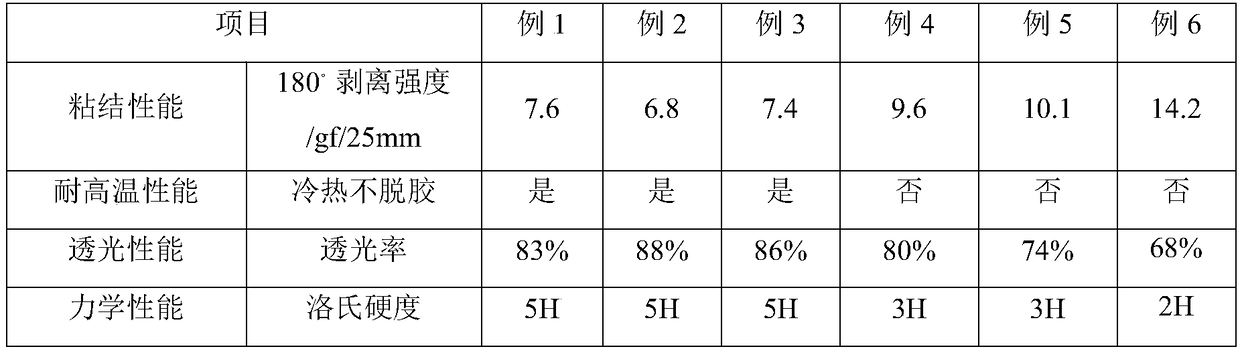

Examples

preparation example Construction

[0024] Correspondingly, the present invention also provides a preparation method of the PET protective film described in the above technical solution, comprising the following steps: coating the low-viscosity film on the corona-treated PET film, and drying it in an oven at 90°C , cool down, and attach a protective layer on the side coated with low-viscosity glue to obtain a PET protective film. It consists of parts by weight of functional monomer, 0.2-2 parts by weight of emulsifier, 0.5-3 parts by weight of initiator and 50-80 parts by weight of deionized water. The initiator is 1-methyl-3-peroxybenzyl Acyl imidazolium bromide salt ionic liquid.

[0025] Compared with the prior art, the present invention has the following advantages and beneficial effects:

[0026] (1) PET protective film of the present invention is made up of PET substrate layer, low-viscosity intermediate layer and protective layer, and its preparation process is simple, easy to operate, and is suitable fo...

Embodiment 1

[0034] The preparation method of initiator is as follows:

[0035]Add 1-methylimidazolium bromide, benzoyl chloride and sodium bicarbonate to hydrogen peroxide, wherein the molar ratio of N-methylimidazolium bromide, benzoyl chloride, sodium bicarbonate and hydrogen peroxide is 1:1:0.2:2 , stirred at 50° C. for 12 hours at 500 r / min, and vacuum-dried at 80° C. for 24 hours to obtain an initiator, which is ready for use.

[0036] The low-viscosity intermediate layer is formed by low-viscosity glue, and the low-viscosity glue is made of 100 parts by weight of viscosity monomer ethyl acrylate, 30 parts by weight of internal polymer monomer methyl acrylate, and 10 parts by weight of functional monomer (meth)glycidyl acrylate , 2 parts by weight of emulsifier SDS, 0.5 parts by weight of initiator and 80 parts by weight of deionized water, the specific preparation method is as follows:

[0037] (4) Stir the viscous monomer, internal polymer monomer and functional monomer at room te...

Embodiment 2

[0042] The preparation method of initiator is as follows:

[0043] Add 1-methylimidazolium bromide, benzoyl chloride and sodium bicarbonate to hydrogen peroxide, wherein the molar ratio of N-methylimidazolium bromide, benzoyl chloride, sodium bicarbonate and hydrogen peroxide is 1:1:0.25:3 , stirred at 80° C. for 6 hours at 1000 r / min, and vacuum-dried at 80° C. for 24 hours to obtain an initiator, which was set aside.

[0044] The low-viscosity middle layer is formed by low-viscosity glue, which consists of 100 parts by weight of viscous monomer butyl acrylate, 20 parts by weight of internal polymer monomer styrene, and 8 parts by weight of functional monomer N-methylolacrylamide acrylamide , 1 weight part of emulsifier SDBS, 2 weight parts of initiator and 50 weight parts of deionized water, the specific preparation method is as follows:

[0045] (7) Stir the viscous monomer, internal polymer monomer and functional monomer at room temperature for 0.5 h at 1000 r / min to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com